Low-voltage low-loss electrolytic capacitor paper and preparation method and application thereof

An electrolytic capacitor paper, low-loss technology, applied in the field of low-voltage low-loss electrolytic capacitor paper and its preparation, can solve the problems of weakening the fiber bonding force in the wet paper web, poor fiber fiber bonding force, and short circuit of the electrolytic capacitor, so as to improve the quality of the paper Strength, good absorption, and the effect of reducing the short circuit rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

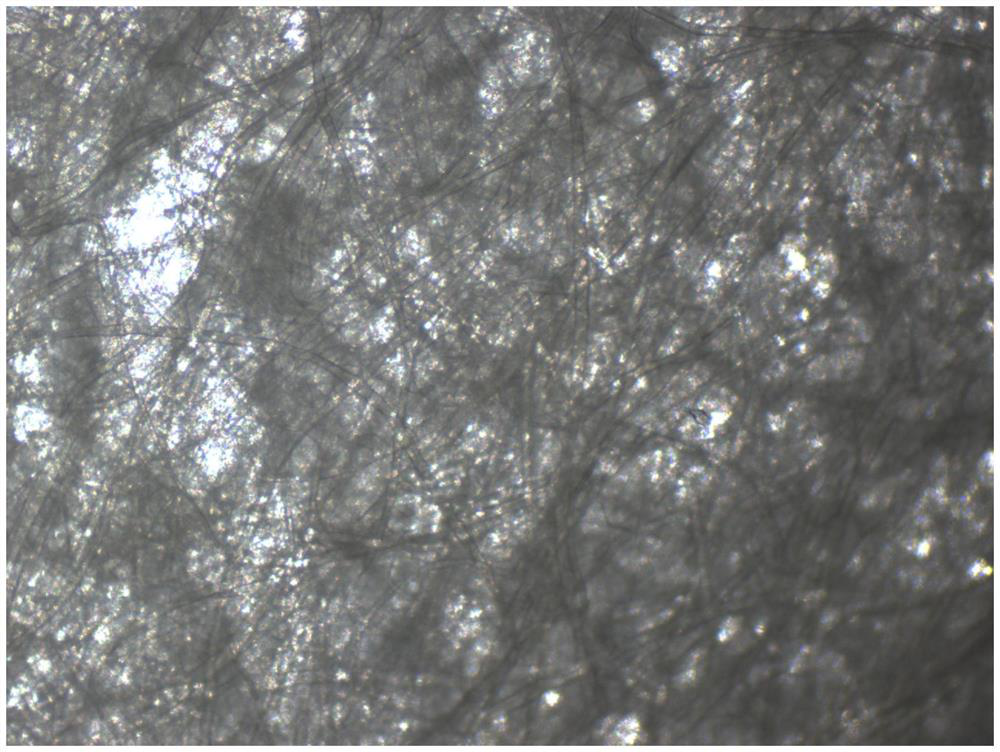

Image

Examples

example 2

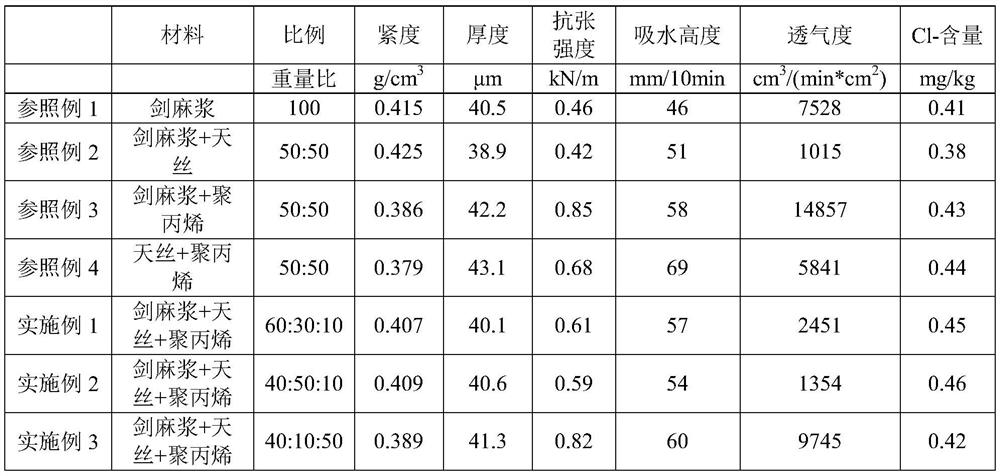

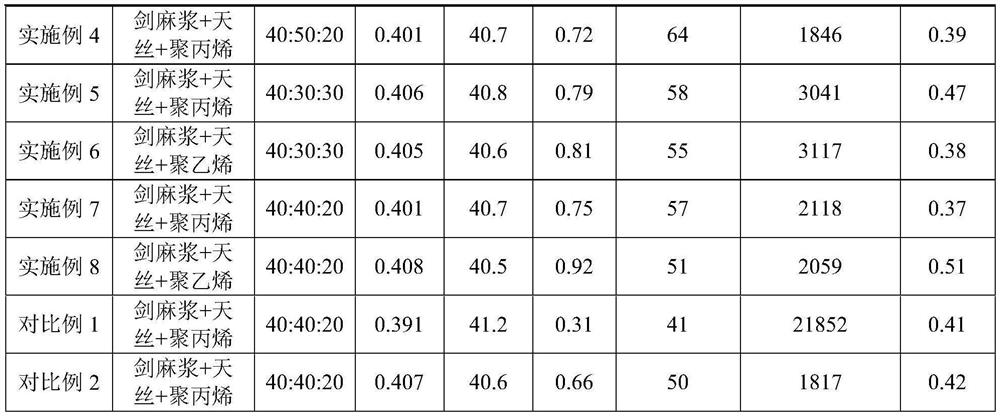

[0047] The beating degree of sisal pulp is 25°SR, the beating specific energy is 200kW*h / t, the tencel fiber is soaked for 24 hours and then beating, the beating degree is 50°SR, the beating specific energy is 60kW*h / t, the sisal pulp and tencel The fibers are mixed according to the absolute dry weight of 50% and 50% respectively, and sent to the paper machine papermaking system, and 0.05% of the total dry weight of the raw materials is added to the batching box of the paper machine flow delivery system. Non-ionic polyacrylamide solution , using inclined wire paper machine papermaking, papermaking process according to the conventional process.

[0048] Reference example 3

[0049] The beating degree of sisal pulp is 25°SR, the beating specific energy is 200kW*h / t, the specification of polypropylene fiber is 1.0dtex*5mm, the polypropylene fiber is stirred and dispersed for 40 minutes, and then filtered through a 60-mesh filter, and then added again Ionized water is configured ...

example 4

[0051] Tencel fibers are soaked for 24 hours and then beaten, the degree of beating is 50°SR, the specific energy of beating is 60kW*h / t, the specification of polypropylene fibers is 1.0dtex*5mm, the polypropylene fibers are stirred and dispersed for 40 minutes, and then filtered through a 60-mesh filter. After filtering, deionized water is added to form a fiber suspension with a concentration of 0.1% to 1.0%. The tencel pulp and polypropylene fiber are mixed at 50% and 50% by absolute dry weight and sent to the paper machine papermaking system. Add non-ionic polyacrylamide solution of 0.05% relative to the dry weight of the raw materials in the batching box of the paper machine flow delivery system, and use an inclined wire paper machine for papermaking. The base paper obtained by papermaking is shaped by a sizing machine, and the surface temperature of the sizing dryer is 240 ℃, setting speed 100m / min, setting once.

Embodiment 1

[0053] The beating degree of sisal pulp is 25°SR, the beating specific energy is 200kW*h / t, the tencel fiber is soaked for 24 hours and then beating, the beating degree is 50°SR, the beating specific energy is 60kW*h / t, and the specification of polypropylene fiber is 1.0dtex *5mm, polypropylene fibers were stirred and dispersed for 40 minutes, and then filtered through a 60-mesh filter. After filtration, deionized water was added to make a fiber suspension with a concentration of 0.1% to 1.0%. Sisal pulp, tencel fibers and polypropylene The fibers are mixed and sent to the paper machine papermaking system according to the dry weight ratio of 60%, 30%, and 10%, and 0.05% of the total dry weight of the raw materials is added to the batching box of the paper machine. The acrylamide solution is made by inclined wire paper machine, and the base paper obtained by papermaking is shaped by a setting machine. The surface temperature of the setting drying cylinder is 240°C, the setting s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com