Method for making hand-made paper by dry method

A kind of soil paper and dry method technology, which is applied in papermaking, paper machine, textile and papermaking, etc. It can solve the problems of uncontinuous production, low production efficiency, large water consumption, etc., and achieve low cost, fast burning speed and high output of a single machine Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

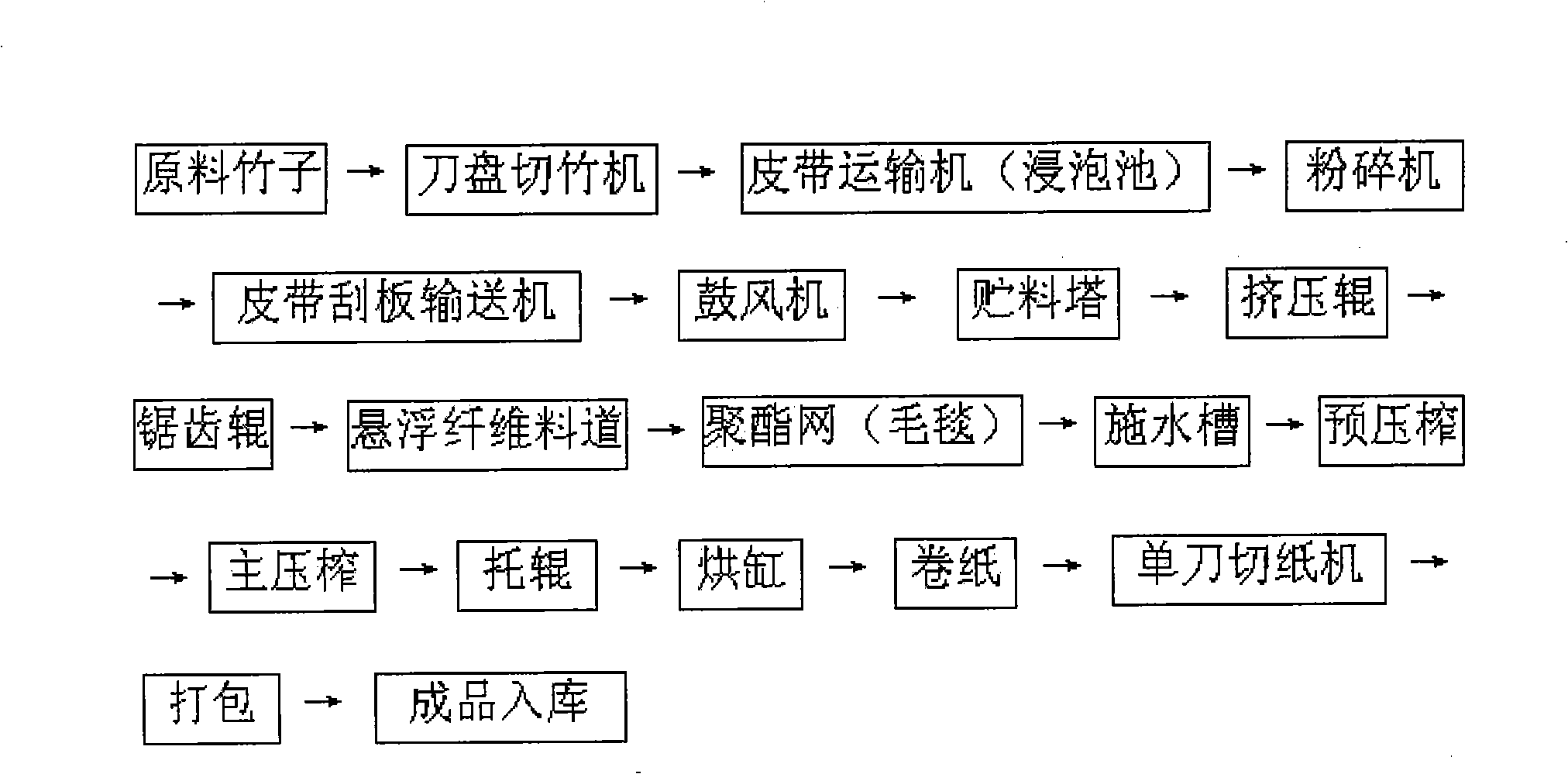

[0038] The raw bamboo is cut into bamboo slices with a length of 30mm-50mm with a knife-disc bamboo cutting machine. The bamboo slices are slowly passed through the lye pool with a belt conveyor. The time is generally 5-10 minutes. The lye used is 10-20. % Sodium hydroxide solution, the bamboo chips in the lye pool are stacked for 24 hours to fully absorb the lye, so that the lignin between the fibers is dissolved, and then the bamboo chips after absorbing the lye are input into the crusher, the crusher There is a high-speed rotating flying blade to cut the bamboo material, splitting the filaments, and brooming the fiber. The high-speed rotating flying blade collides with the raw material, and the friction generates a large amount of heat energy to reduce the water content of the crushed pulp from 40% to 15%. Heating and evaporating the moisture of the pulp can meet the requirements of the pulp required by the dry-laid paper machine and save energy.

[0039] The dry pulp in the pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com