Coating-enhanced carbonization-free solid electrolytic capacitor paper and preparation method thereof

A technology of electrolytic capacitor paper and solid-state electrolysis, applied in special paper, paper, papermaking, etc., can solve problems such as large energy consumption, high heating temperature, and structural damage of cathode and anode foils, so as to ensure smooth production, reduce side reactions, The effect of improving adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

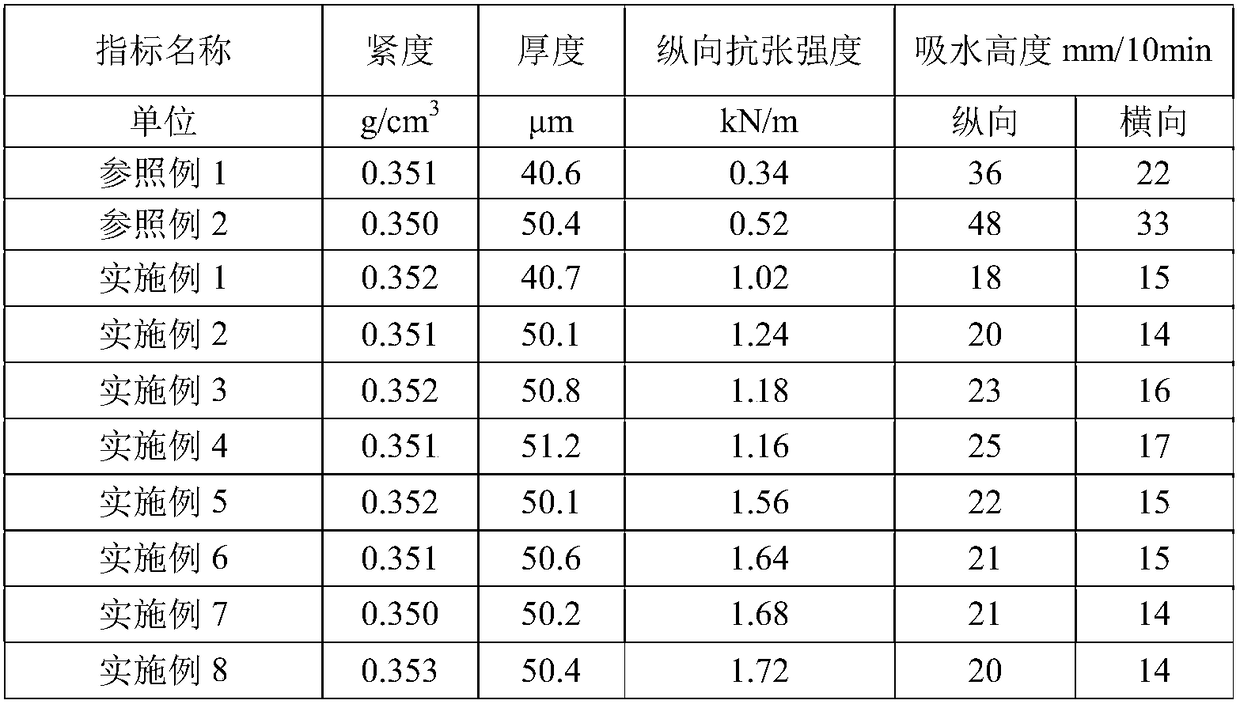

Examples

example 2

[0024] The beating degree and wet weight of the unbleached softwood pulp after deflaking were 13 °SR and 17.5g respectively, and the pulp concentration after deflaking was 2%; after the PET polyester fiber was dispersed, the pulp concentration was 2%, the fiber length was 6mm, and the fineness was 1.5 dtex. Mix the two kinds of fibers. After mixing, Manila wood pulp and PET polyester fiber account for 40% and 60% of the total fiber dryness respectively. After mixing, the slurry concentration is 1%. Forming, forming on the Internet with a concentration of 0.1%, and then obtaining the finished product after pressing, drying, coiling and cutting.

Embodiment 1

[0026] The beating degree and wet weight of the unbleached softwood pulp after deflaking were 13 °SR and 17.5g respectively, and the pulp concentration after deflaking was 2%; after the PET polyester fiber was dispersed, the pulp concentration was 2%, the fiber length was 5mm, and the fineness was 0.5dtex. Mix the two kinds of fibers. After mixing, the wood pulp and PET polyester fiber account for 50% and 50% of the total fiber dryness respectively. The pulp concentration after mixing is 1%. After the two fibers are evenly mixed, they are formed by a rotary screen , the online forming concentration is 0.05%, and then the finished product is obtained after pressing, drying, spray coating, drying, coiling and slitting. The coating liquid is polyvinyl alcohol aqueous solution, the mass concentration is 1.5%, and the coating amount is coating 2.4% of the absolute dry mass of the final paper.

Embodiment 2

[0028] The beating degree and wet weight of the unbleached softwood pulp after deflaking were 13 °SR and 17.5g respectively, and the pulp concentration after deflaking was 2%; after the PET polyester fiber was dispersed, the pulp concentration was 2%, the fiber length was 6mm, and the fineness was 1.5 dtex. Mix the two kinds of fibers. After mixing, the wood pulp and PET polyester fiber account for 50% and 50% of the total fiber dryness respectively. The pulp concentration after mixing is 1%. After the two fibers are evenly mixed, they are formed by a rotary screen , the online forming concentration is 0.1%, and then the finished product is obtained after pressing, drying, spray coating, drying, coiling and slitting. The coating liquid is a polyvinyl alcohol aqueous solution with a mass concentration of 1.8%, and the coating amount is 3.0% of the absolute dry mass of the final paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com