Double-layer papermaking process for paper-making reconstituted tobacco and equipment for double-layer papermaking process

A technology of reconstituted tobacco leaf and papermaking method, which is applied in the double-layer papermaking process of reconstituted tobacco leaf by papermaking method and its equipment field. It can solve the problems of poor uniformity of the ratio of added fiber pulp and tobacco pulp, affecting production efficiency, and many fine components. The effect of large length, improved utilization efficiency, and less impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

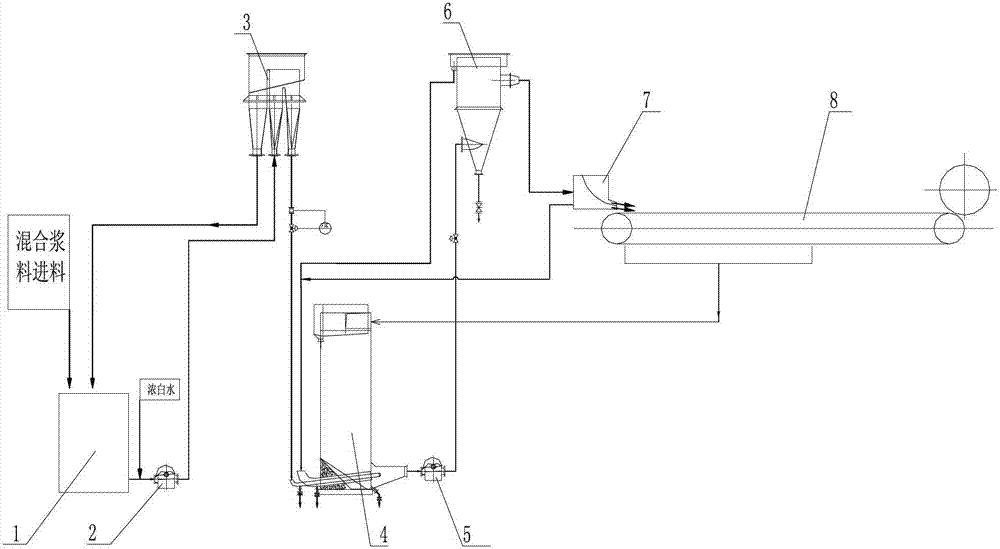

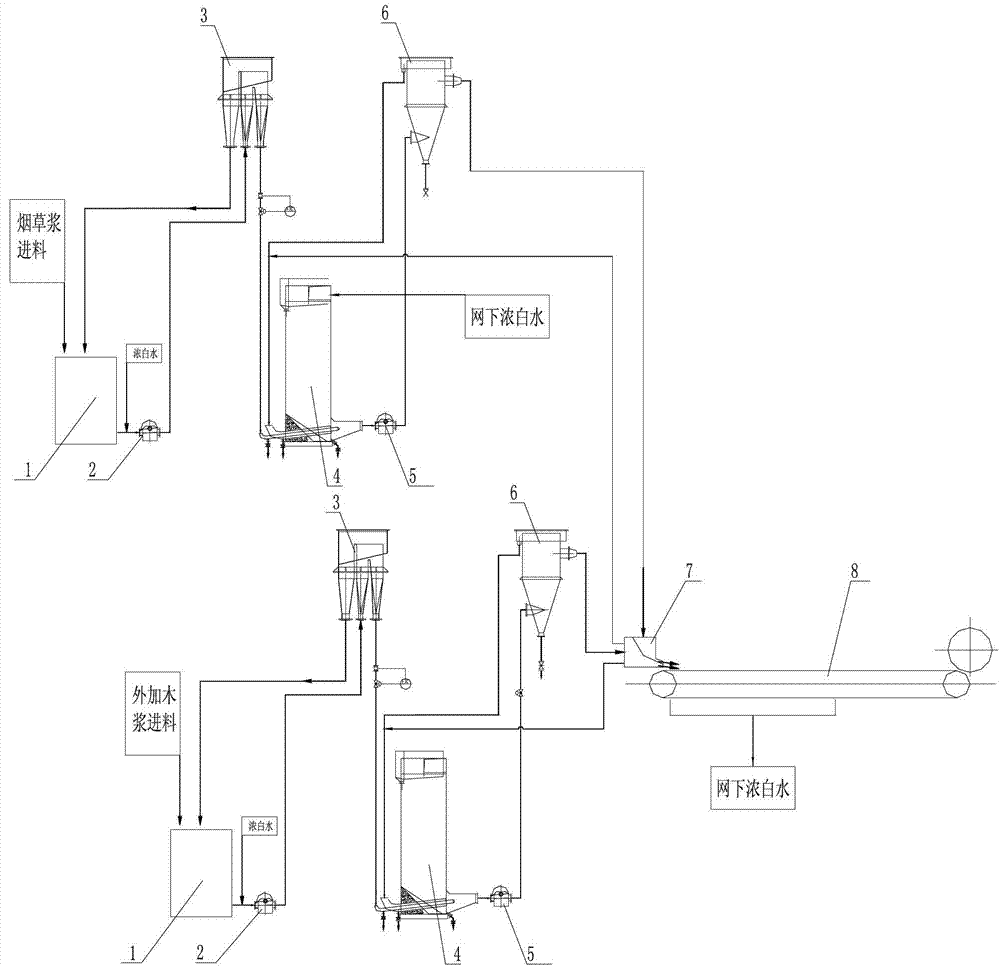

[0023] 1. Independent pulp preparation: Tobacco pulp and fiber pulp are prepared separately,

[0024] Wherein, the weight configuration ratio of tobacco and water is 2.5%.

[0025] The weight configuration ratio of added fiber and water is 2.5%.

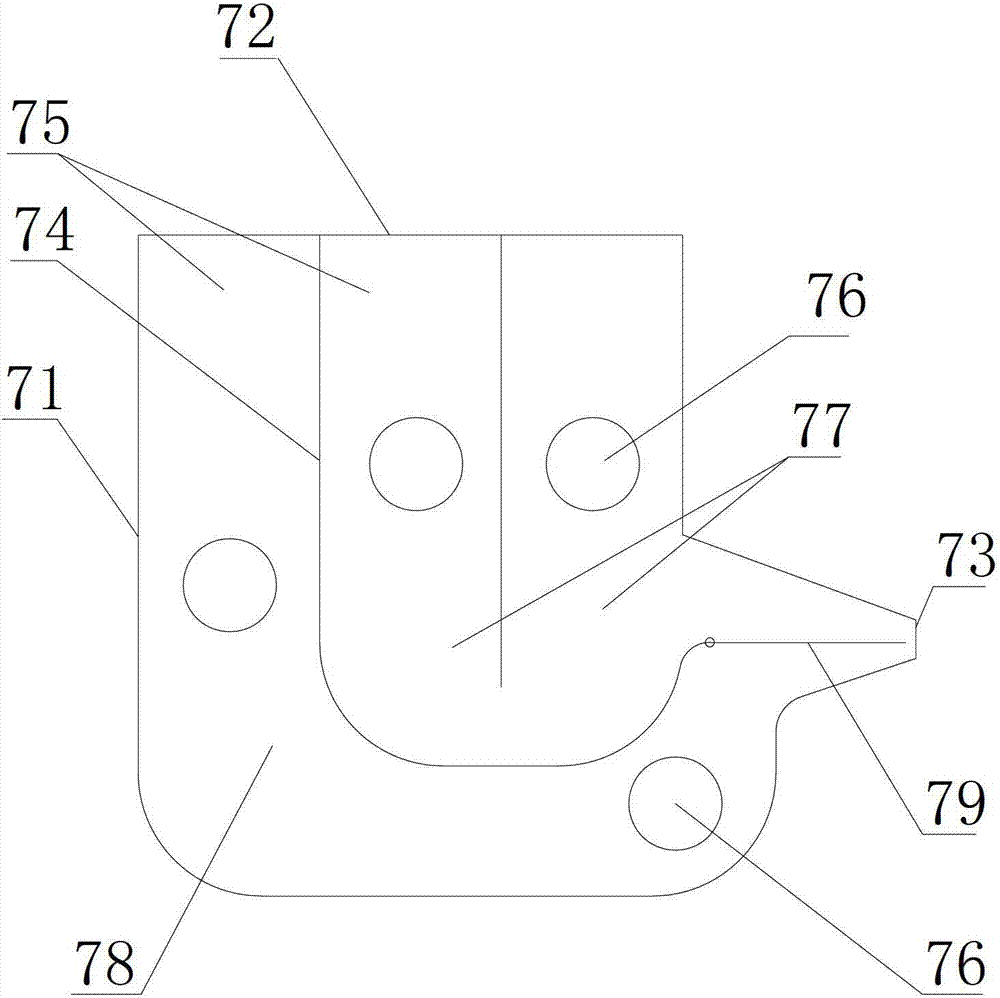

[0026] Heading: Send the configured tobacco pulp and additional fiber pulp into the double-layer headbox, and when the pulp is discharged from the double-layer headbox, in the formed slurry, the tobacco pulp is located in the upper layer, and the added wood pulp is located in the lower layer . When the pulp is discharged from the double-layer headbox, the flow rate ratio of the added wood pulp pulp and tobacco pulp is 1:5.

[0027] The specific parameters of the final product

[0028] 10% increase in tensile strength,

[0029] The fine fiber content in concentrated white water is less than 0.1%.

[0030] Product yield increased by 10%

Embodiment 2

[0032] 1. Independent pulp preparation: Tobacco pulp and fiber pulp are prepared separately,

[0033] Wherein, the weight configuration ratio of tobacco and water is 3%.

[0034] The weight configuration ratio of the added fiber and water is 3%.

[0035] Heading: Send the configured tobacco pulp and additional fiber pulp into the double-layer headbox, and when the pulp is discharged from the double-layer headbox, in the formed slurry, the tobacco pulp is located in the upper layer, and the added wood pulp is located in the lower layer . When the pulp is discharged from the double-layer headbox, the flow rate ratio of the added wood pulp pulp and tobacco pulp is 1:6.

[0036] The specific parameters of the final product

[0037] Tensile strength increased by 8.5%,

[0038] The fine fiber content in concentrated white water is less than 0.1%.

[0039] Product yield increased by 8.6%

Embodiment 3

[0041] 1. Independent pulp preparation: Tobacco pulp and fiber pulp are prepared separately,

[0042] Wherein, the weight configuration ratio of tobacco and water is 3.2%.

[0043] The weight configuration ratio of added fiber and water is 3.2%.

[0044] Heading: Send the configured tobacco pulp and additional fiber pulp into the double-layer headbox, and when the pulp is discharged from the double-layer headbox, in the formed slurry, the tobacco pulp is located in the upper layer, and the added wood pulp is located in the lower layer . When the pulp is discharged from the double-layer headbox, the flow rate ratio of the added wood pulp pulp and tobacco pulp is 1:7.

[0045] The specific parameters of the final product

[0046] Tensile strength increased by 8%,

[0047] The fine fiber content in concentrated white water is less than 0.1%.

[0048] Product yield increased by 8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com