Laser markable polyethylene composition and preparation method thereof

A technology for laser marking and polyethylene, which is applied to the field of laser-markable polyethylene composition and its preparation, can solve the problems of high price, excessive addition of laser marking, decreased physical properties of materials, etc. The effect of good laser marking and improved impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

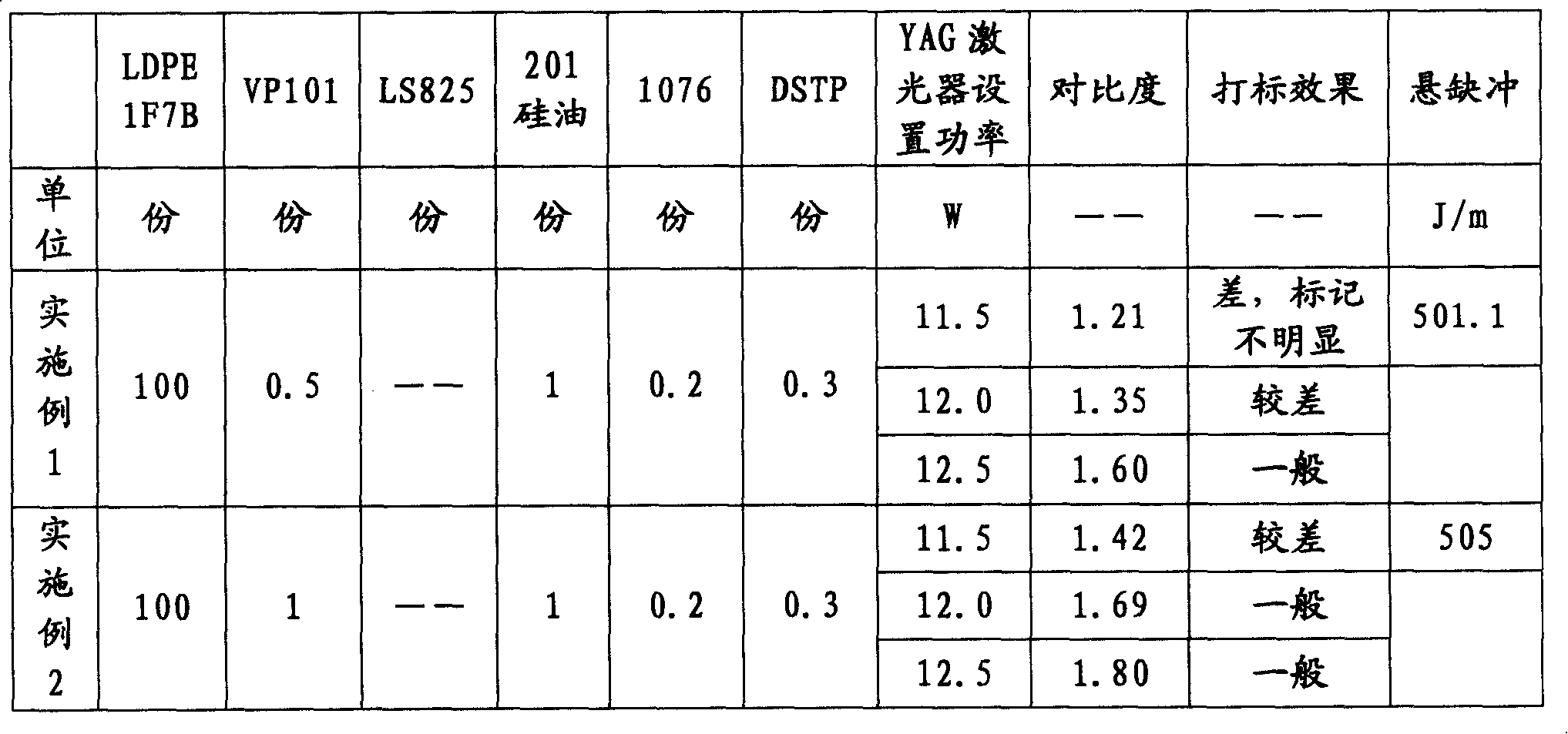

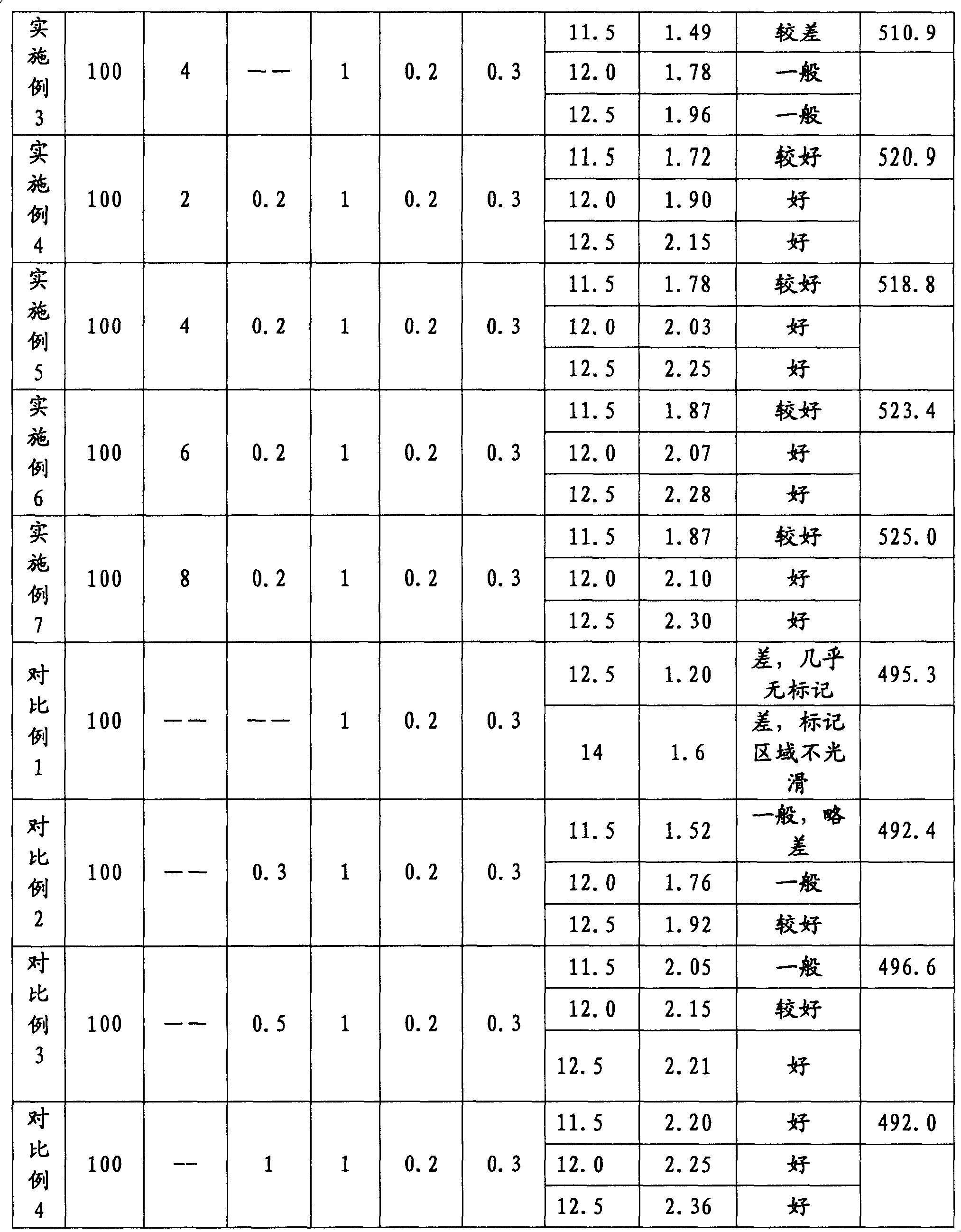

Embodiment 1~7

[0036] Put polyethylene resin (low-density polyethylene, LDPE, grade 1F7B, Yanshan Branch of Sinopec) and simethicone (grade 201, viscosity of 1000 centipoise, Beijing Second Chemical Plant) in a high-speed mixer for processing; then The treated polyethylene, ultrafine fully vulcanized powder styrene-butadiene rubber (brand VP101, Beijing Beihuayan Chemical New Technology Co., Ltd., particle size 80nm, gel content 90%), laser additives (brand LS825, Merck, Germany) , Antioxidant 1076 (Beijing Chemical No. 3 Factory) and Antioxidant DSTP (Beijing Chemical No. 3 Factory) are mixed evenly, then the mixture is added to the twin-screw extruder (Germany WP company, model ZSK-25) for melting After mixing and extruding, pelletizing, the extrusion temperature is 130~190℃, and the screw speed is 300rpm. Dry the extruded pellets in an oven at 80°C for 6 hours, and then inject them into standard specimens at 150-210°C for laser marking tests and related performance tests. The specific formula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com