Die-cutting machine with waste recovering function

A waste recycling and die-cutting machine technology, applied in metal processing, etc., can solve the problems of single die-cutting, low utilization rate of raw materials, increased production costs, etc., to achieve the effect of reducing raw material costs, improving operation value, and facilitating later use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

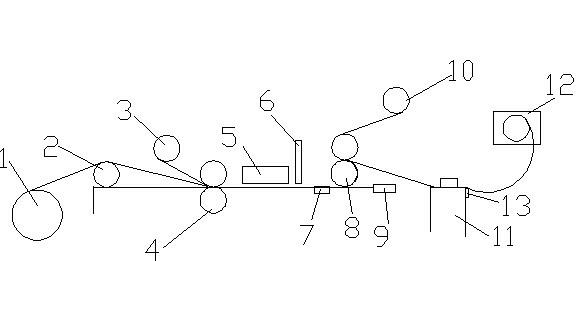

[0014] like figure 1 As shown, a die-cutting machine with waste recycling function is installed with a feeding device 1, a stripping device 2, a mounting bracket 3, a peritoneal stick 4, a die-cutting seat 5, a second-degree electric eye device 6, and a waste coiling device in sequence. 10 and a rewinding and cutting device 9, a composite material rubber stick 8 is installed between the second-degree electric eye device 6 and the waste coiling device 10, and a release paper device 12 is installed behind the composite material rubber stick 8.

[0015] After the material enters the die-cutting device, the finished product is taken up by the rewinding and cutting device 9, and the die-cut waste material and the release paper on the release paper device 12 pass through the composite material rubber roller 8 synchronously, and the waste material is pasted on the On the rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com