Method for preparing manganese-aluminium hard-magnetic alloy

A hard magnetic alloy and alloy technology, applied in the field of manganese-aluminum hard magnetic alloy manufacturing, can solve the problem of high magnetic properties, achieve the effects of improved magnetic properties, low cost of raw materials, and easy operation and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] First determine the molecular formula of the manganese-aluminum alloy, calculate the mass percentage of each element (as shown in Table 1) and weigh the corresponding weight (raw material purity: 99wt% or higher). The alloy raw materials smelted in a vacuum induction furnace are used to make ingot billets.

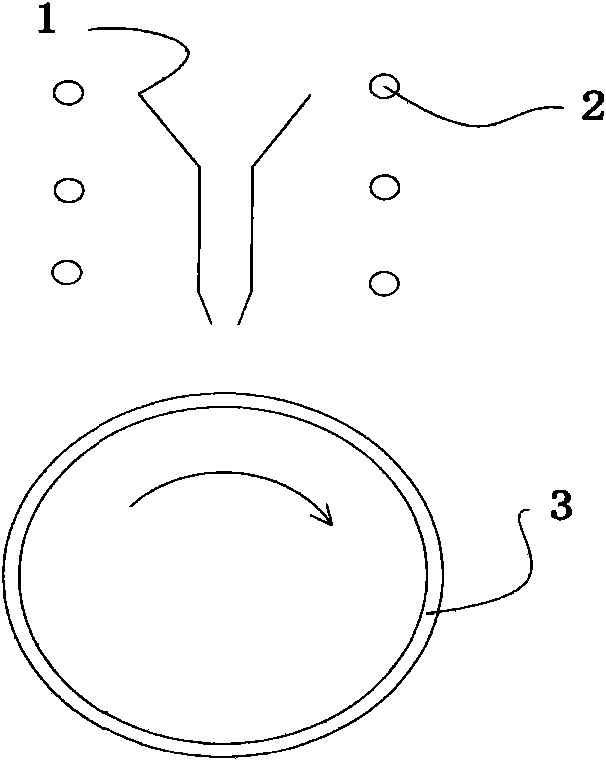

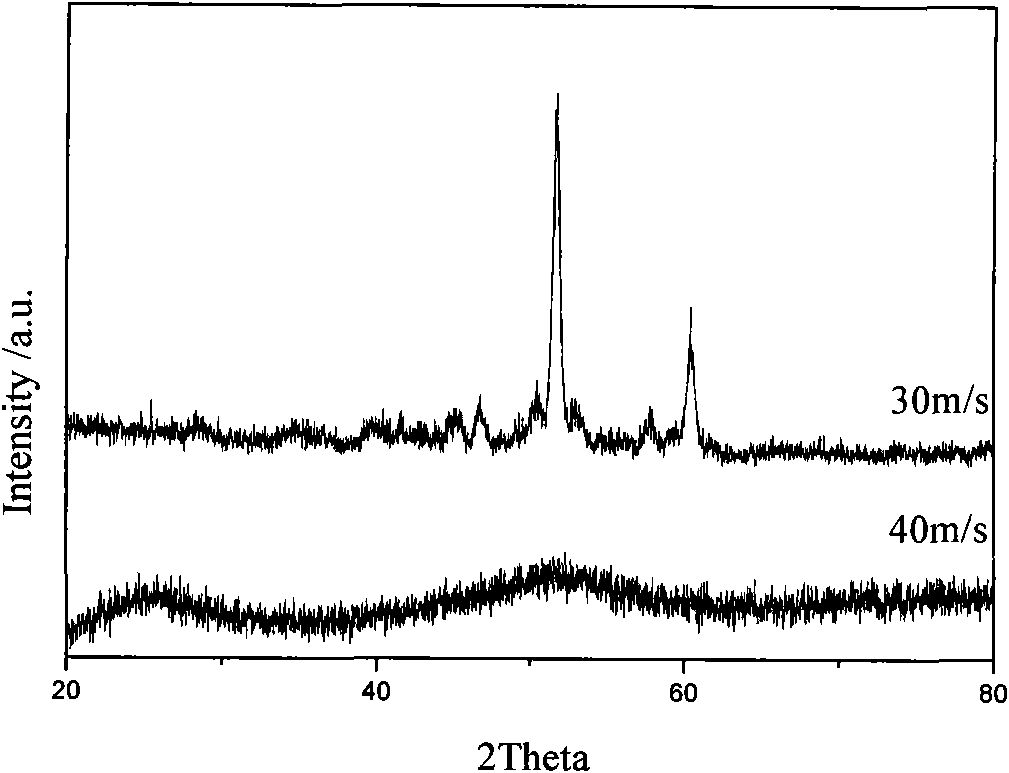

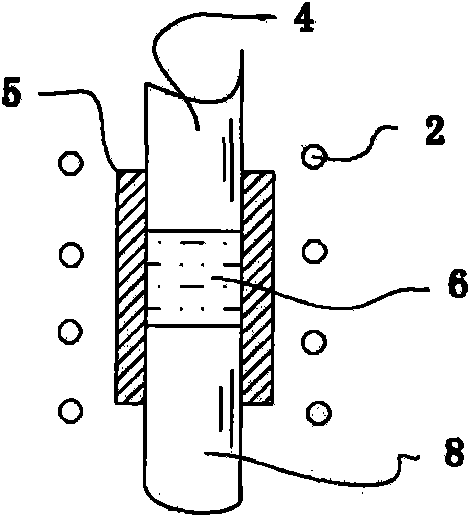

[0039] Using rapid quenching equipment (such as figure 1 ), the molten alloy is loaded into the crucible 1, the heating source 2 provides heat to the molten state, pours it on the water-cooled copper roller 3 rotating at a peripheral speed of 30-50 m / s, and the cooling rate is close to 10 6 °C / sec. A collection bucket or collection tank can be set in the direction of the alloy thin strip injection. The thickness of the thin alloy strip is about 20-50 μm. The X-ray diffraction pattern of the alloy powder is as figure 2 As shown, when the line speed of the copper roll is 40 m / s, the alloy powder presents an amorphous structure; when the line speed of the copper r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com