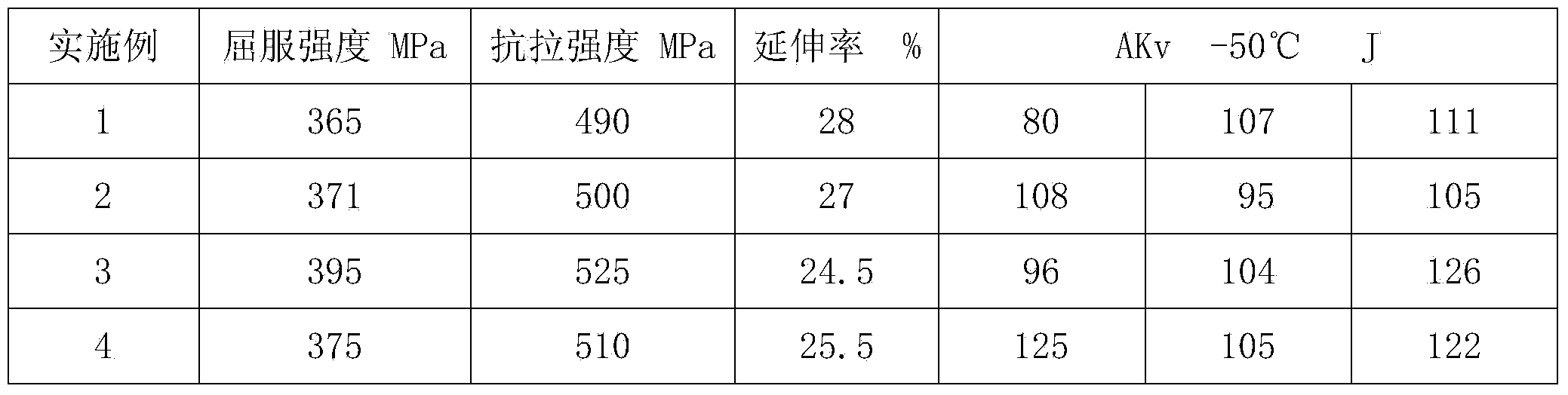

355MPa-class thick plate and production method thereof

A production method and technology for steel plates, applied in the field of high-strength extra-thick steel plates and their production, can solve the problems of cumbersome processes, uneven performance of normalized extra-thick steel plates, and high production costs, so as to improve production efficiency, improve remedial effects, and reduce raw materials. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific chemical composition is shown in Table 1.

[0031] Table 1 Example 1 chemical composition wt% content table

[0032] C

Si

mn

P

S

V

Cr

Ti

als

N

0.16

0.33

1.6

0.012

0.004

0.05

0.039

0.01

0.029

0.0149

[0033] Converter nitrogen blowing volume 68m 3 / min, tapping temperature 1640℃, tapping Als0.065%;

[0034] The argon station controls the bottom blowing argon flow rate at 37m 3 / min; the argon blowing time is 4min; the nitrogen content in the molten steel at the argon outlet station is 0.018%.

[0035] The billet thickness is 300mm, heated to 1150°C, kept for 240min, soaking time 90min.

[0036] The rolling start temperature is 1120°C, the deformation of each pass is controlled at 15%-25%, and the final rolling temperature is 965°C. The thickness of the finished steel plate is 130mm;

[0037] After rolling, it is air-cooled to 550°C, the stacking height is 3.6...

Embodiment 2

[0039] The specific chemical composition is shown in Table 2.

[0040] Table 2 Example 1 chemical composition wt% content table

[0041] C

Si

mn

P

S

V

Cr

Ti

als

N

0.145

0.18

1.5

0.013

0.003

0.03

0.038

0.011

0.027

0.015

[0042] Converter nitrogen blowing volume 65m 3 / min, tapping temperature 1610℃, tapping Als0.066%;

[0043] The argon station controls the bottom blowing argon flow rate at 40m 3 / min; the argon blowing time is 3min; the nitrogen content in the molten steel at the argon outlet station is 0.0173%.

[0044] The billet thickness is 250mm, heated to 1170°C, held for 200min, soaking time 90min.

[0045] The starting rolling temperature is 1160°C, the deformation of each pass is controlled at 15%-25%, and the final rolling temperature is 943°C. The thickness of the finished steel plate is 80mm;

[0046] After rolling, it is air-cooled to 670°C, the stacking height is...

Embodiment 3

[0048] The specific chemical composition is shown in Table 3.

[0049] Table 3 Example 3 chemical composition wt% content table

[0050] C

Si

mn

P

S

V

Cr

Ti

als

N

0.132

0.27

1.65

0.01

0.002

0.037

0.028

0.008

0.015

0.013

[0051] Converter nitrogen blowing volume 55m 3 / min, tapping temperature 1630℃, tapping Als0.058%;

[0052] The argon station controls the bottom blowing argon flow rate at 45m 3 / min; 3.5min when blowing argon; the nitrogen content in molten steel at the argon outlet station is 0.0156%.

[0053] The billet thickness is 230mm, heated to 1150°C, held for 180min, and soaked for 70min.

[0054] The starting rolling temperature is 1145°C, the pass deformation is controlled at 15%-25%, and the final rolling temperature is 935°C. The thickness of the finished steel plate is 50mm;

[0055] After rolling, air-cool to 700°C, the stacking position is 5m high, and the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com