Preparation process of environmental protection liner paper

A preparation process and a technology for liner paper, applied in the field of preparation technology of environmentally friendly liner paper, can solve the problems of complex preparation process, large power consumption and high energy consumption, and achieve the effects of low raw material cost, low power consumption and obvious energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

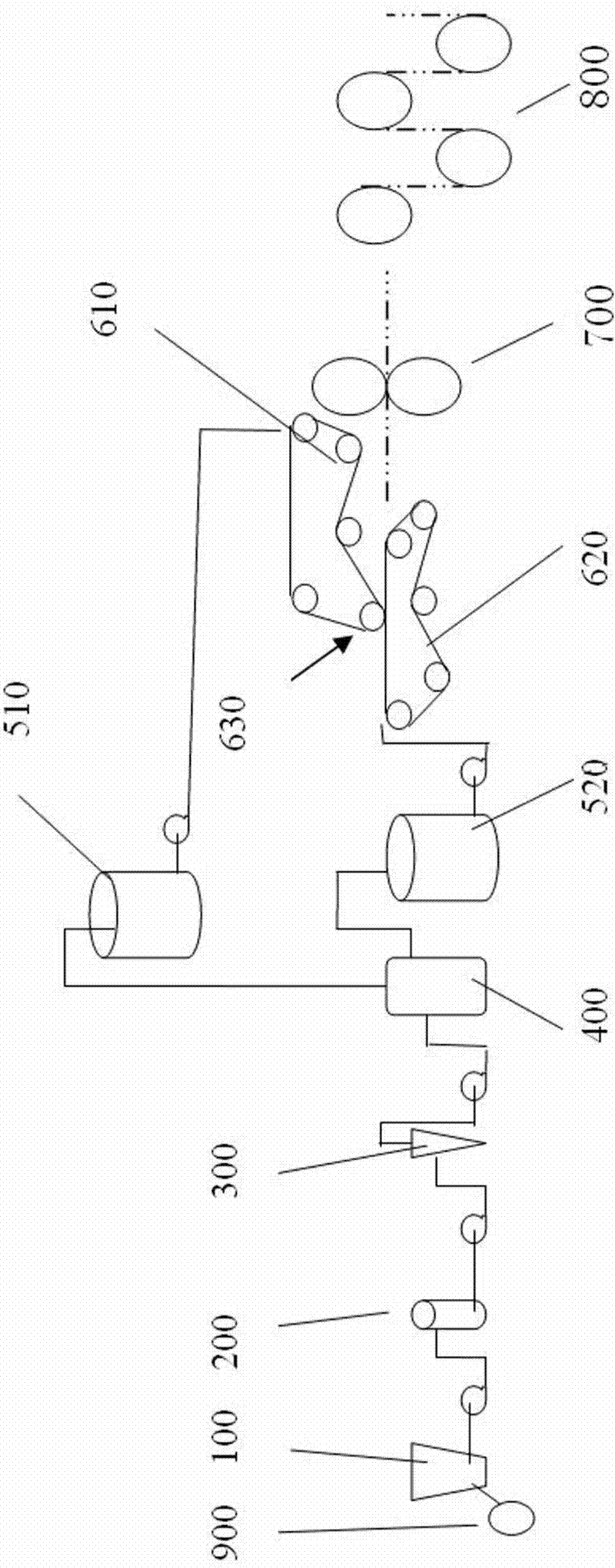

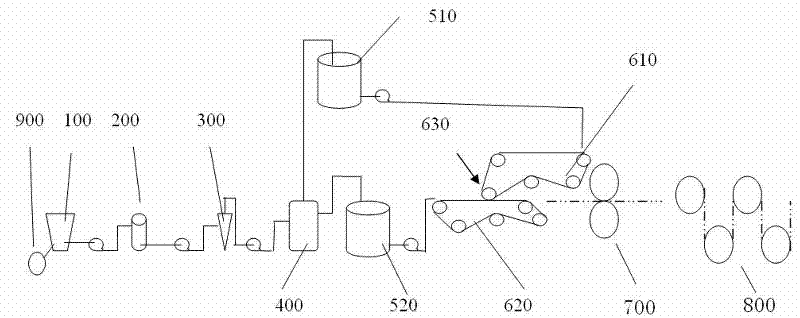

[0048] A kind of preparation technology of environment-friendly liner paper adopts such as figure 1 The apparatus shown is carried out, including the following steps.

[0049] a, Add national waste and European waste as waste paper to the pulper 100 for disintegration, and the undisintegrated large pieces of pulp in the pulper are further processed by the hydraulic slag cleaner 900 to form pulp. The ratio of national waste and European waste is average Set to 1:2~1:4. The choice of national waste and European waste as raw materials has the characteristics of low cost. The hydraulic slag cleaner 900 can effectively remove impurities, increase the strength of early slag removal, and ensure product quality.

[0050] b. Afterwards, the pulp passes through the coarse screen 200 and the deslagging device 300 to remove impurities.

[0051] c. The pulp after impurity removal is input to the classifying screen 400, and the classifying screen 400 divides the pulp into long fibers and...

Embodiment 2

[0060] A kind of preparation technology of environment-friendly liner paper adopts such as figure 1 The apparatus shown is carried out and includes the following steps.

[0061] a, Add national waste and European waste as waste paper to the pulper 100 for disintegration, and the undisintegrated large pieces of pulp in the pulper are further processed by the hydraulic slag cleaner 900 to form pulp. The ratio of national waste and European waste is average Set to 1:2~1:4. The choice of national waste and European waste as raw materials has the characteristics of low cost. The hydraulic slag cleaner 900 can effectively remove impurities, increase the strength of early slag removal, and ensure product quality.

[0062] b. Afterwards, the pulp passes through the coarse screen 200 and the deslagging device 300 to remove impurities.

[0063] c. The pulp after impurity removal is input to the classifying screen 400, and the classifying screen 400 divides the pulp into long fibers a...

Embodiment 3

[0072] A kind of preparation technology of environment-friendly liner paper adopts such as figure 1 The apparatus shown is carried out and includes the following steps.

[0073] a, Add national waste and European waste as waste paper to the pulper 100 for disintegration, and the undisintegrated large pieces of pulp in the pulper 100 are further processed by the hydraulic slag cleaner 900 to form pulp, the ratio of national waste and European waste The setting is 3:7, that is, the content of national waste is 30%, and the content of European waste is 70%. The choice of national waste and European waste as raw materials has the characteristics of low cost. The hydraulic slag cleaner 900 can effectively remove impurities, increase the strength of early slag removal, and ensure product quality.

[0074] b. The pulp passes through the coarse screen 200 and the deslagging device 300 to remove impurities.

[0075] c. The pulp after impurity removal is input to the classifying scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com