Preparation method for ferroferric oxide nano particle targeted MRI contrast agent

A technology of ferric oxide and nanoparticles, applied in preparations for in vivo tests, pharmaceutical formulations, etc., can solve the problems of no iron oxide nanoparticles, etc., achieve good water solubility, easy operation, and efficient targeting sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1.26g FeCl 2 4H 2 Pour O into a beaker, add 7.75mL of ultrapure water, and add 6.25mL of NH 3 ·H 2 O, the above mixed solution was continuously stirred for 10-15 minutes under the air atmosphere, so that the ferrous iron was fully oxidized, and then the mixed solution was transferred to a high-pressure reactor. 0.52g PEI was ultrasonically dissolved in 5mL aqueous solution, transferred to the reactor with a pipette gun, fully mixed with the solution in the reactor, and reacted at 134°C for 3 hours. After the reaction was over, it was naturally cooled to room temperature, and the obtained black precipitate Fe 3 o 4 -PEI magnetic separation to remove the supernatant, add an appropriate amount of ultrapure water to ultrasonically disperse, and then magnetically separate, repeat the ultrapure water washing five times to remove impurities, and then redisperse in 20mL ultrapure water to obtain PEI coating Fe 3 o 4 Nanoparticles (Fe 3 o 4 -PEI).

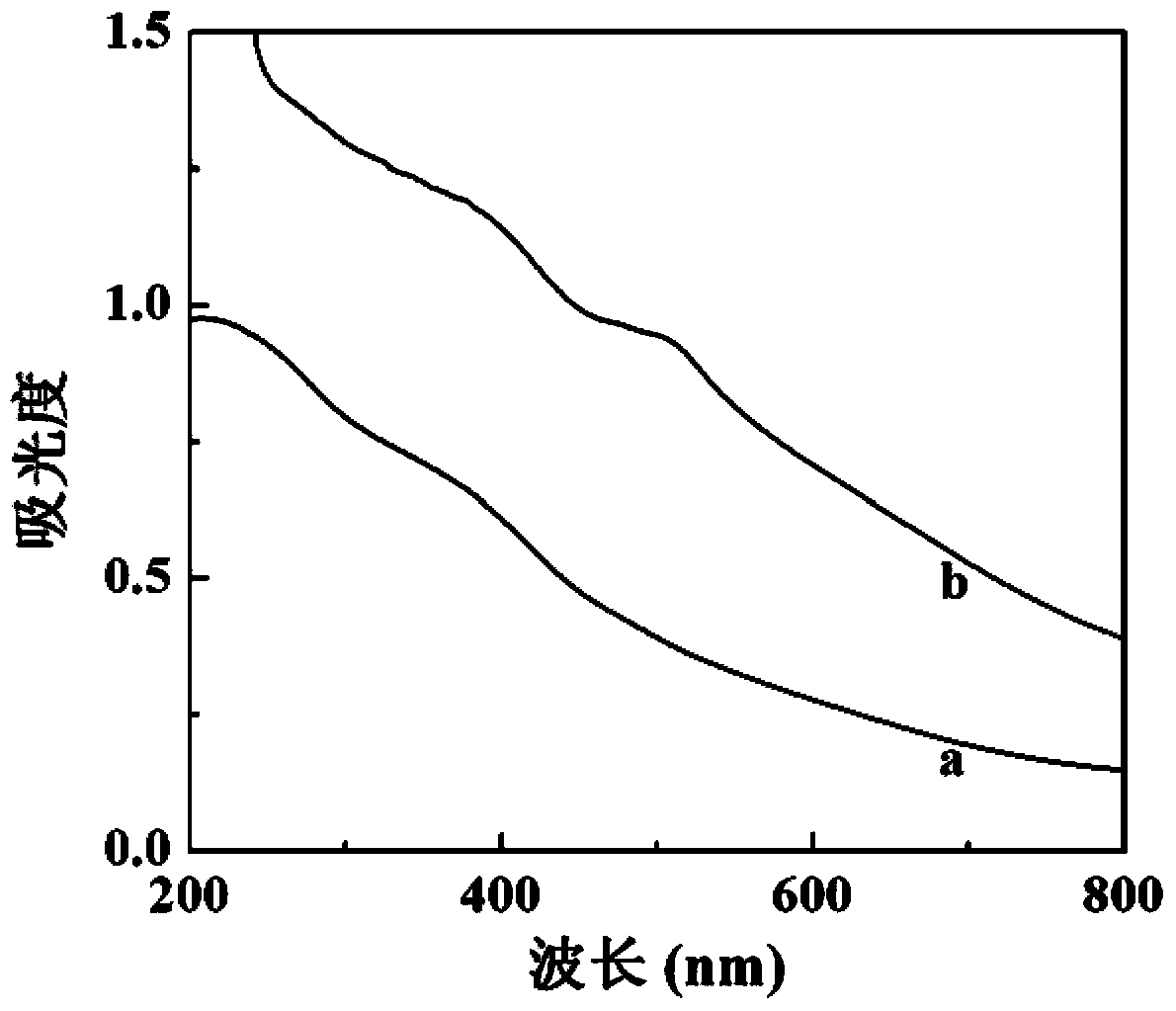

[0066] Take the pre...

Embodiment 2

[0069] HA with different molecular weights (Mw=5805, 23.5mg; Mw=31200, 124.8mg) were dissolved in 5mL ultrapure water at 70°C, and then 5mL containing EDC (7.7mg) and NHS (4.6mg) were added to it. DMSO solution. After the solution was mixed evenly, it was stirred and activated for 3h. Then the activated HA solution was added dropwise to 4 mL of Fe prepared in Example 1. 3 o 4 -in PEI-FI solution, stirred and reacted for three days, then washed with ultrapure water magnetic separation, and redispersed in 5mL ultrapure water to obtain HA-modified Fe with different molecular weights 3 o 4 Aqueous solutions of nanoparticles (respectively defined as Fe 3 o 4 -PEI-FI-HA 6K and Fe 3 o 4 -PEI-FI-HA 31K ).

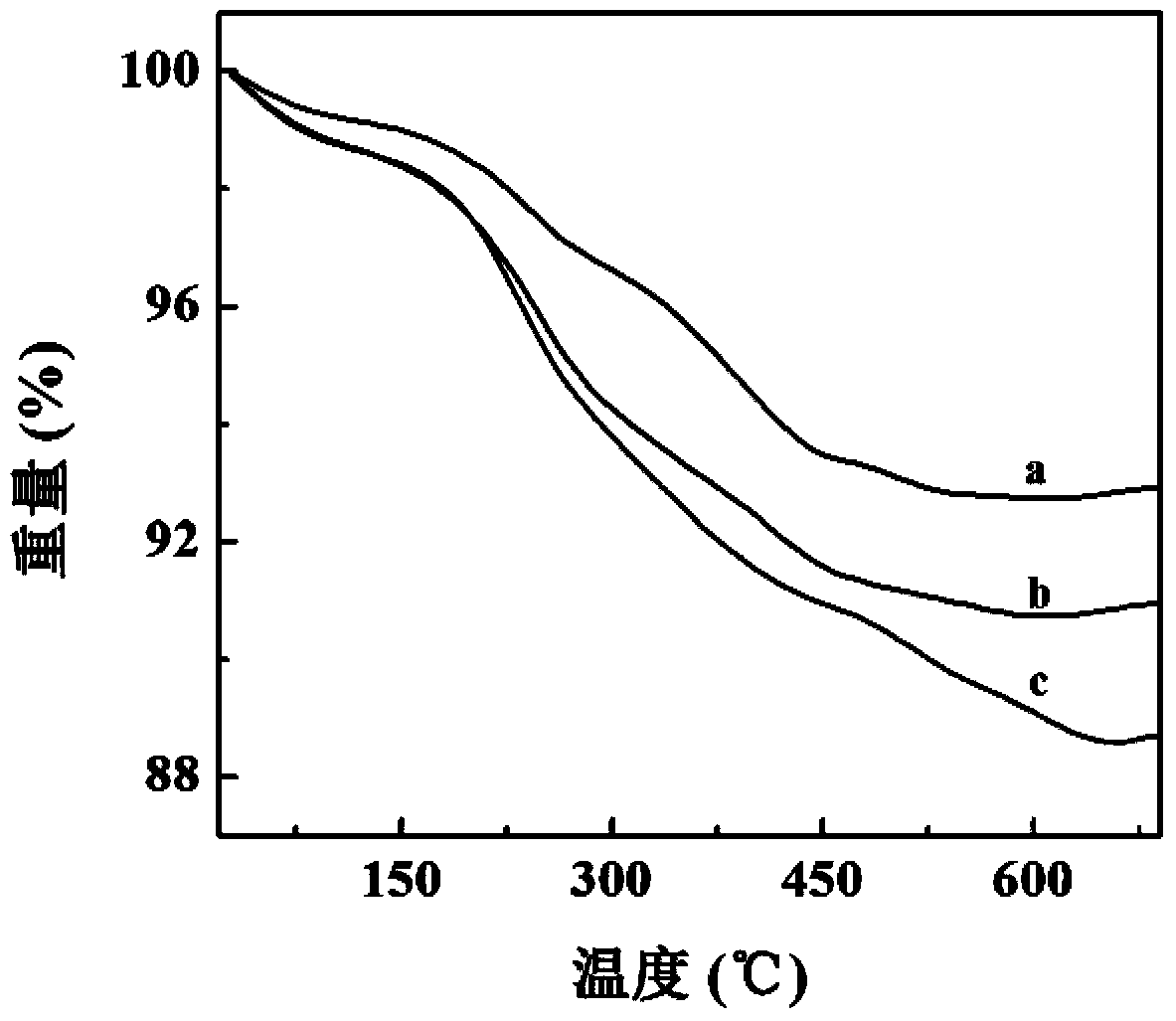

[0070] Take Fe 3 o 4 -PEI-FI (Example 1), Fe 3 o 4 -PEI-FI-HA 6K and Fe 3 o 4 -PEI-FI-HA 31K 0.5 mL each of the aqueous solution was vacuum freeze-dried, and then the three materials were subjected to thermogravimetric analysis (e.g. figure 2 shown). Depend on ...

Embodiment 3

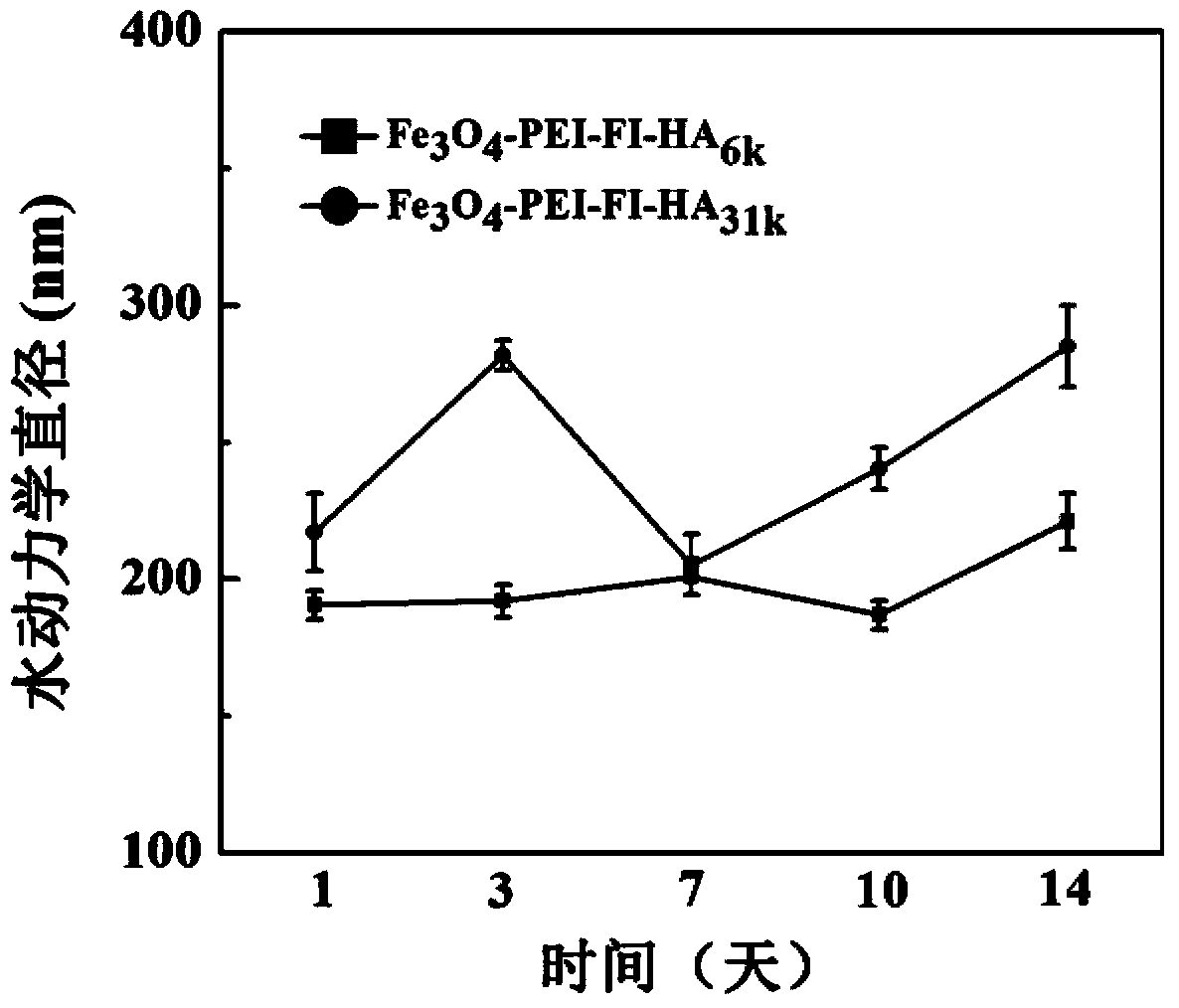

[0072] Take Fe respectively 3 o 4 -PEI-FI (Example 1), Fe 3 o 4 -PEI-FI-HA 6K and Fe 3 o 4 -PEI-FI-HA 31K (Example 2) Each 0.1mL aqueous solution was prepared with ultrapure water to prepare 1.5mL aqueous solutions for measuring surface potential (as in Table 1) and hydrodynamic diameter (as in image 3 ). Potentiometric results showed that Fe 3 o 4 -The surface potential of PEI-FI nanoparticles reached +26.1mV. After modification, the obtained Fe 3 o 4 -PEI-FI-HA 6K and Fe 3 o 4 -PEI-FI-HA 31K The surface potential of the nanoparticles decreased to -16.3mV and -21.9mV, respectively.

[0073] The results further proved that HA was successfully modified to the surface of nanoparticles. Subsequently, we measured the prepared Fe 3 o 4 -PEI-FI-HA 6K and Fe 3 o 4 -PEI-FI-HA 31K The hydrodynamic diameter of nanoparticles at different storage times was used to evaluate their colloidal stability, such as image 3 shown. Fe 3 o 4 -PEI-FI-HA 6K and Fe 3 o 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com