Method for preparing annular moderate-temperature Ag-Cu-Sn brazing filler metal piece

A technology of ag-cu-sn and circular ring, which is applied in the field of preparation of circular Ag-Cu-Sn medium-temperature solder, can solve the problems such as the difficulty of forming medium-temperature solder, and achieve the reduction of raw material costs, easy control, and particle size The effect of uniform diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

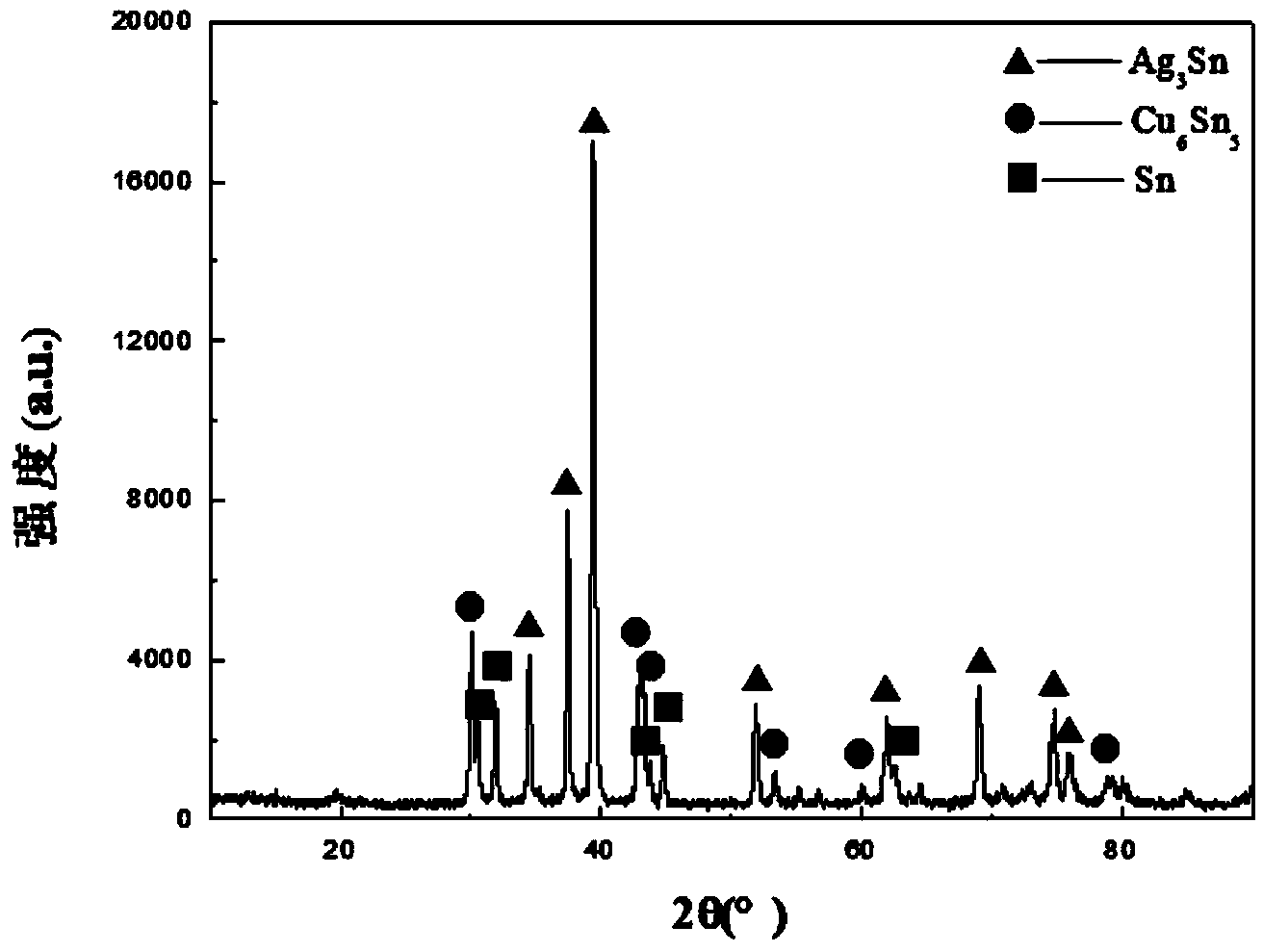

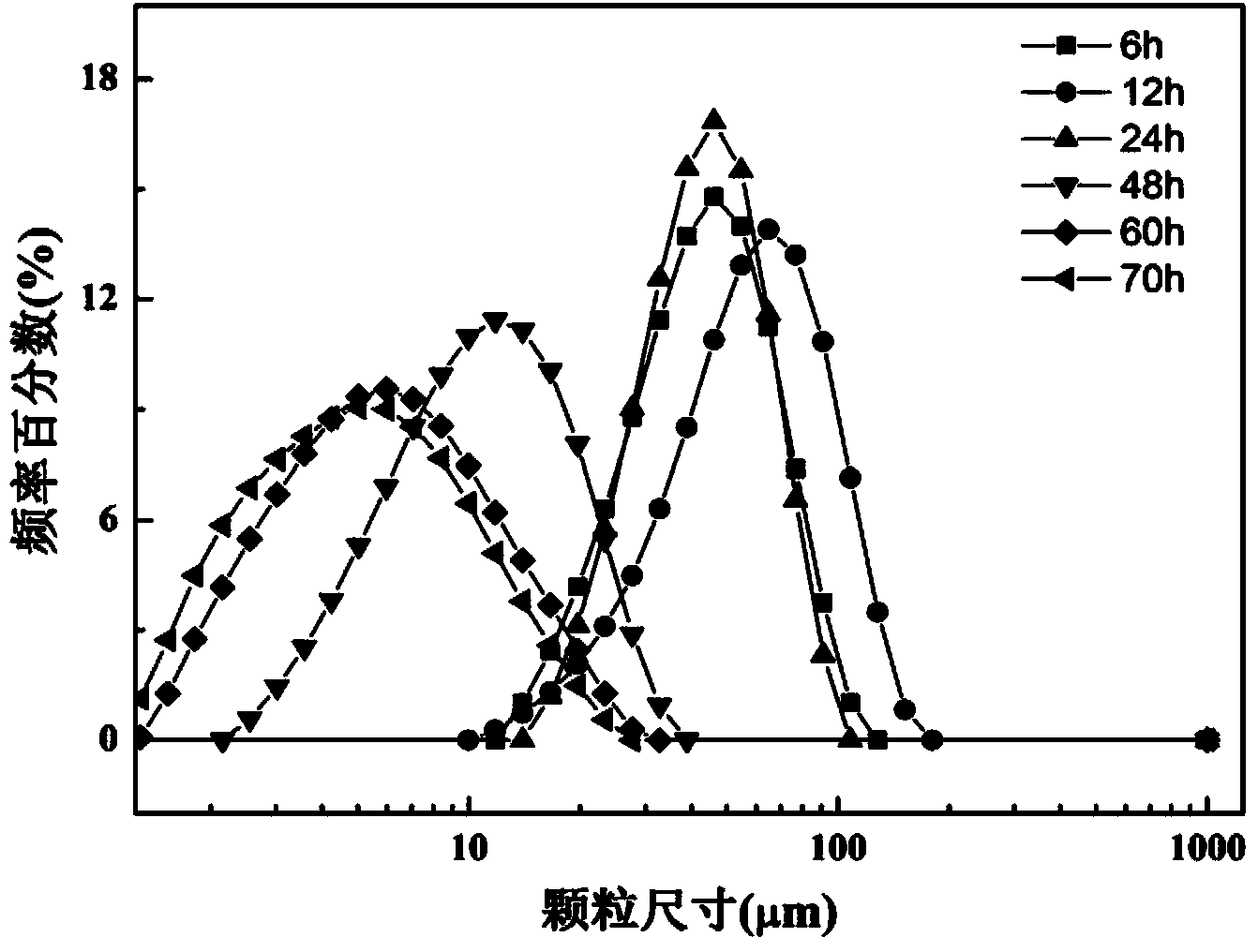

[0021] Ag powder, Cu powder and Sn powder were used as the original powder in the experiment. Choose Ag content 43 wt.%, Sn content 45 wt.%, Cu content 12 wt.%. The particle size range of the Ag powder is 2-10 μm, the particle size range of the Cu powder is 2-15 μm, and the particle size range of the Sn powder is 20-35 μm. According to the ratio of ball to material 2:1, put it into a polytetrafluoroethylene ball mill tank, the diameter of the carbide ball is 6, 8 and 10mm, the ratio is 40:50:10, and the ball mill tank is filled with argon protective gas . The speed of the ball mill is 200-500r / min, and the ball milling time is 40-70h. After ball milling, place the alloyed powder in a designed ring-shaped mold with an outer diameter of Φ5 and an inner diameter of Φ3, and press with a pressing pressure of 5-35 MPa to obtain an alloy sheet with an outer diameter of Φ5 and an inner diameter of Φ3 and a thickness of 200 μm. Finally, the formed alloy sheet is placed in a reducing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com