Multifunctional dura mater repairing material based on biomimetic design and preparation method thereof

A technology for repairing materials and dura mater, which is applied in medical science, nonwovens, filament/thread forming, etc. It can solve the problems of liquid leakage, difficulty in large-scale production and application, and adhesion, so as to reduce production costs and raw materials Cost, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A multifunctional dura mater repair material based on bionic design and a preparation method thereof, comprising the following steps:

[0040] 1) Electrospun polylactic acid film

[0041] Inject 1ml of 8.5% (W / V) PLLA (polylactic acid) stirred magnetically for 24 hours into a glass syringe (D=12mm). The molecular weight of polylactic acid in the polylactic acid solution is 286,000, and the solvent is dichloromethane. No. needle, set the distance between the positive and negative electrodes to 15cm, the positive voltage to 10V, the negative voltage to -5V, and the propulsion rate to 0.5ml / h for electrospinning to form a polylactic acid electrospinning film with a micron thickness and a diameter of about 1 micron.

[0042] 2) Electrospun chitosan-polylactic acid film

[0043] A solution of chitosan and polylactic acid containing 2.5% w / v total amount was magnetically stirred for 24 hours, wherein the mass ratio of chitosan and polylactic acid was 8:2, and the solvent was...

Embodiment 2

[0048] A multifunctional dura mater repair material based on bionic design and a preparation method thereof, comprising the following steps:

[0049] 1) Electrospun polylactic acid film

[0050] Inject 1ml of 6% (W / V) PLLA (polylactic acid) stirred magnetically for 24 hours into a glass syringe (D=12mm). The molecular weight of polylactic acid in the polylactic acid solution is 286,000, and the solvent is dichloromethane. No. needle, set the distance between the positive and negative electrodes to 15cm, the positive voltage to 10V, the negative voltage to -5V, and the propulsion rate to 0.5ml / h for electrospinning to form a polylactic acid electrospinning film with a micron thickness and a diameter of about 1 micron.

[0051] 2) Electrospun chitosan-polylactic acid film

[0052] A solution of chitosan and polylactic acid containing 2.5% w / v total amount was magnetically stirred for 24 hours, wherein the mass ratio of chitosan and polylactic acid was 8:2, and the solvent was h...

Embodiment 3

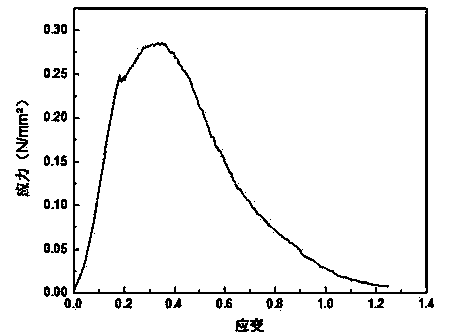

[0058] Such as figure 1 As shown, the surface of the hydrogel layer structure is very smooth, which is the general surface morphology of the hydrogel after drying. The hydrogel layer at the junction of the hydrogel-double-layer spinning membrane is located under the spinning, showing uneven Morphology; moreover, chitosan-PLA spun-embedded within the hydrogel layer and connected the hydrogel layers. Among them, in the interface between the hydrogel and the spinning, the chitosan-polylactic acid spinning wrapped in the polylactic acid spinning is closely combined with the hydrogel, and drives the polylactic acid to combine with the hydrogel, so that the surface of the polylactic acid wraps a layer of hydrogel.

[0059] Human cerebrospinal fluid was prepared in vitro according to the formula of cerebrospinal fluid, and the contact angle experiment was carried out on the electrospun surface of polylactic acid in the material. The results show that the average value of the contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com