UV-curable organosilicon pressure-sensitive adhesive composition

A silicon pressure-sensitive adhesive and composition technology, applied in the direction of adhesives, etc., can solve the problems of high viscosity of the system, difficulty in coating, difficulty in reaching the degree of cross-linking, etc., and achieve excellent high temperature resistance, increase in cross-linking density and cohesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

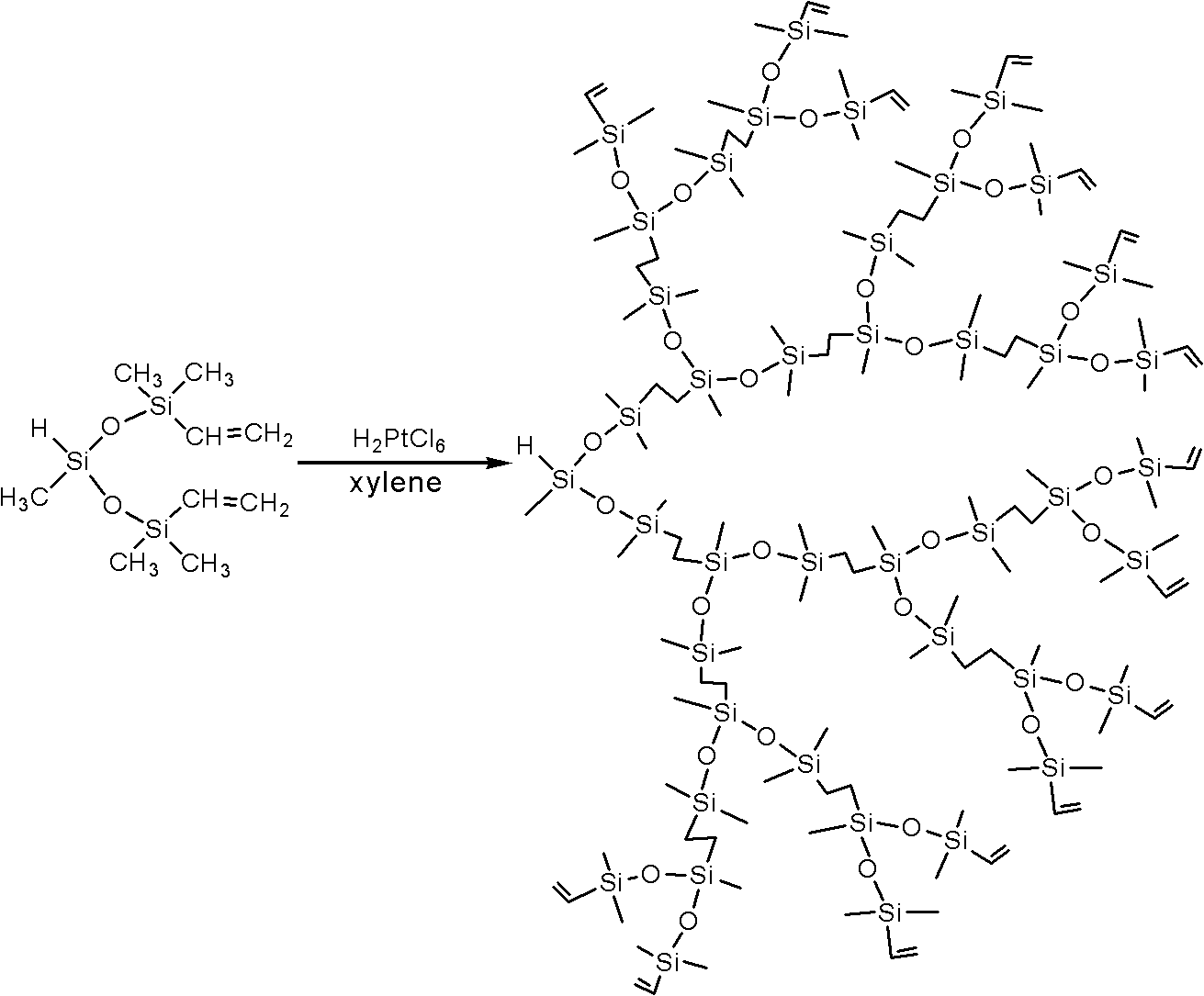

[0027] 1. Preparation of unsaturated hyperbranched polyorganosiloxane:

[0028] Take methyl-bis(dimethyl-vinyl)siloxysilane as AB 2 Type monomer, under chloroplatinic acid catalyzed hydrosilylation reaction to prepare unsaturated hyperbranched polyorganosiloxane. Add 50mL xylene, 10g monomeric methyl-bis(dimethyl-vinyl)siloxysilane and 0.1g chloroplatinic acid catalyst to a 100mL round-bottomed flask successively, and react in a constant temperature oil bath at 60°C with magnetic stirring. Monitor the progress of the reaction by FTIR, when there is no silicon-hydrogen bond characteristic absorption peak in the reaction system (IR: 2159cm -1 )

[0029] end the reaction. Then the solvent xylene was distilled off under reduced pressure to obtain a colorless liquid which was unsaturated hyperbranched polyorganosiloxane. The hyperbranched polyorganosiloxane has a branching degree DB=0.4; a molecular weight Mn=8000. Its synthesis and structure are shown in the following formula...

Embodiment 2

[0034] The UV-curable silicone pressure-sensitive adhesive composition described in this embodiment consists of the following components:

[0035] Example 1 gained unsaturated hyperbranched polyorganosiloxane: 35 grams;

[0036] Methyl vinyl MQ tackifying silicone resin [MQ ratio is 0.8, molecular weight Mn=6000]: 65 grams;

[0037] Photoinitiator: 2-hydroxy-2-methyl-1-phenylacetone: 0.72 grams;

[0038] Catalyst: Dibutyltin dilaurate: 0.15 g.

[0039] The composition is coated on a polyester film with a thickness of 30um, the thickness of the adhesive layer is controlled to be 20um, and placed under a 2KW high-pressure mercury lamp to irradiate for 1.5min at a distance of 15cm to obtain a silicone pressure-sensitive adhesive tape. Initial adhesion performance: 20#; Peel strength: 9.6N / 25mm; Holding performance: 33.4h. The composition was coated on a release film, the thickness of the adhesive layer was controlled to be 50um, and it was placed under a 2KW high-pressure merc...

Embodiment 3

[0041] The UV-curable silicone pressure-sensitive adhesive composition described in this embodiment consists of the following components:

[0042] Example 1 gained unsaturated hyperbranched polyorganosiloxane: 60 grams;

[0043]Methyl vinyl MQ tackifying silicone resin [MQ ratio is 0.6, molecular weight Mn=9000]: 40 grams;

[0044] Photoinitiator: benzoin ether: 0.12 grams;

[0045] Catalyst: 0.9 g of dibutyltin dilaurate.

[0046] The composition is coated on a polyimide film with a thickness of 30um, the thickness of the adhesive layer is controlled to be 20um, and placed under a 2KW high-pressure mercury lamp for 1.5min irradiation at 15cm to prepare a silicone pressure-sensitive adhesive tape. Initial tack: 11#; Peel strength: 13.5N / 25mm; Stickiness: 632h; Temperature resistance: 280°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

| Temperature resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com