High-temperature-resistant radar and infrared compatible stealth material based on frequency selective surface and preparation method of high-temperature-resistant radar and infrared compatible stealth material

A frequency-selective surface, stealth material technology, applied in chemical instruments and methods, metal material coating processes, manufacturing tools, etc., to achieve the effects of excellent oxidation resistance, low price, and good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

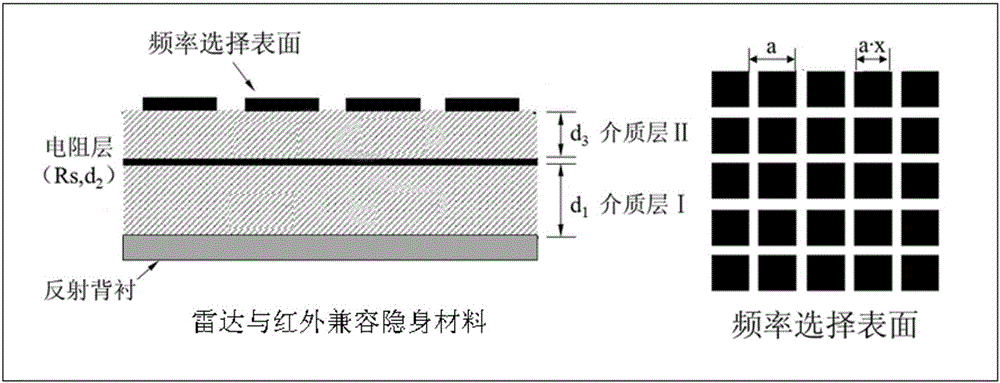

[0048] a kind of like figure 1 The high temperature resistant radar and infrared compatible stealth material based on the frequency selective surface shown in the present invention includes a four-layer structure, including a dielectric layer I, a resistance layer, a dielectric layer II and a frequency selective surface layer in sequence from the inside to the outside, wherein the dielectric layer Layer Ⅰ and dielectric layer Ⅱ are both made of mullite fiber reinforced mullite-based composite material, and the thickness of both dielectric layer Ⅰ and dielectric layer Ⅱ is 2.5mm (that is, d1=d3=2.5mm); the resistance layer is made of ruthenium dioxide Glass-based resistive coating (ruthenium dioxide, RuO 2 is the conductive phase and lead borosilicate glass is the binder), the thickness of the resistance layer is d2=0.02mm; the frequency selective surface layer is composed of metal coatings with high temperature resistance, oxidation resistance and low infrared emissivity in pe...

Embodiment 2

[0061] a kind of like figure 1 The high temperature resistant radar and infrared compatible stealth material based on the frequency selective surface shown in the present invention includes a four-layer structure, including a dielectric layer I, a resistance layer, a dielectric layer II and a frequency selective surface layer in sequence from the inside to the outside, wherein the dielectric layer Layer Ⅰ and dielectric layer Ⅱ are both made of alumina fiber reinforced alumina matrix composite material, the thickness of dielectric layer Ⅰ is d1=2.8mm, the thickness of dielectric layer Ⅱ is d3=2.2mm; the resistance layer is ruthenium dioxide-based glass-based resistance coating (ruthenium dioxide RuO 2 is the conductive phase and lead borosilicate glass is the binder), the thickness of the resistance layer is d2=0.02mm; the frequency selective surface layer is composed of metal coatings with high temperature resistance, oxidation resistance and low infrared emissivity in period...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com