Heat-resisting organic silicon antiseptic inner tank coating

A technology of inner potting paint and silicone, which is applied in the direction of anti-corrosion paint, epoxy resin paint, coating, etc., can solve the problems of motorcycle muffler perforation corrosion, affecting the service life of motorcycle muffler, and loss of protective effect of paint film, etc., to achieve Good corrosion resistance, excellent coating performance, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

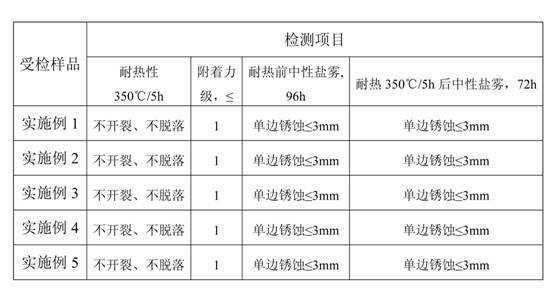

Examples

Embodiment 1

[0030] The composition of the paint is:

[0031] 30 parts of methyl phenyl silicone resin, 5 parts of epoxy modified silicone resin, 1 part of methyl etherified melamine formaldehyde resin, 6 parts of E-44 epoxy resin, 3 parts of natural rosin modified phenolic resin, 108 dispersant 1.2 parts, 0.8 parts of M-5 anti-settling agent, 5 parts of silver powder, 6 parts of zinc powder, 4 parts of zinc chromate, 12 parts of glass powder, 8 parts of mica powder, 7 parts of talcum powder, 7 parts of xylene, 3 parts of butyl ester 1 part, butanol 1 part.

Embodiment 2

[0033] The composition of the paint is:

[0034] 15 parts of methyl phenyl silicone resin, 15 parts of acrylic modified silicone resin, 3 parts of butylated melamine formaldehyde resin, 8 parts of E-12 epoxy resin, 4 parts of natural rosin modified phenolic resin, 108 dispersant 1 part, M-5 anti-settling agent 1 part, zinc powder 6 parts, stainless steel powder 8 parts, zinc chromate 6 parts, mica iron oxide red 5 parts, glass powder 8 parts, mica powder 8 parts, talcum powder 4 parts, two 5 parts of toluene, 2 parts of butyl ester, 1 part of cyclohexanone.

Embodiment 3

[0036] The composition of the paint is:

[0037] 20 parts of methyl phenyl silicone resin, 13 parts of polyester modified silicone resin, 5 parts of butylated melamine formaldehyde resin, 6 parts of E-44 epoxy resin, 1 part of 963 dispersant, M-5 anti-settling agent 1 part, 1 part of KH570 silane coupling agent, 6 parts of silver powder, 4 parts of zinc powder, 2 parts of stainless steel powder, 7 parts of strontium chromate, 5 parts of mica iron oxide ash, 10 parts of glass powder, 9 parts of mica powder, xylene 5 parts, 2 parts of heavy aromatics, 2 parts of butyl ester, 1 part of cyclohexanone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com