High temperature-resistant leakage stopping agent, and preparation method and application thereof

A plugging agent, high temperature resistance technology, applied in chemical instruments and methods, drilling composition and other directions, can solve the problems of poor high temperature resistance, inability to form plugging, etc., achieve stable performance, improve high temperature resistance, high the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

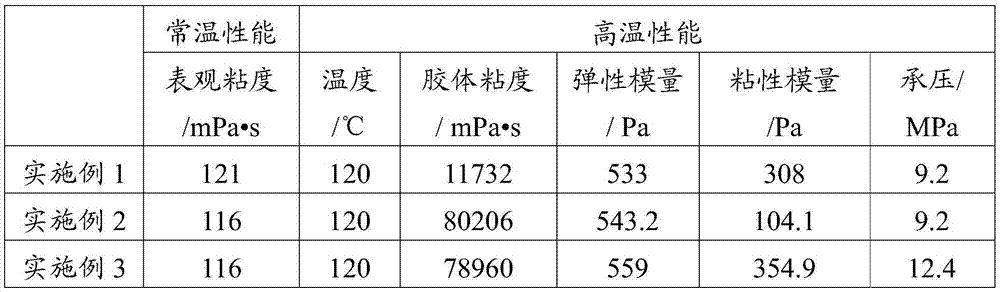

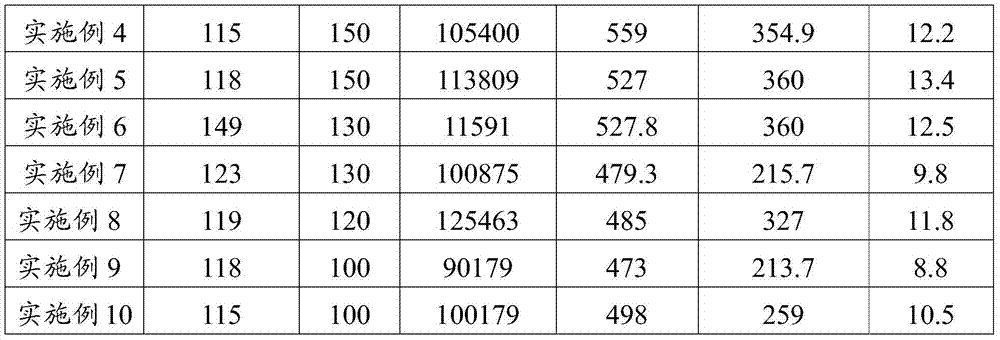

Examples

preparation example Construction

[0057] The lost circulation agent provided by the embodiment of the present invention can be prepared by the following method, and the preparation method includes the following steps:

[0058] Step a, dissolving polyacrylamide in water to obtain a polyacrylamide solution according to a predetermined formula of a leakage stoppage agent;

[0059] Step b, adding sulfonated phenolic resin and hexamethylenetetramine to the polyacrylamide solution, stirring until completely dissolved to obtain a polymer solution;

[0060] Step c, adding alkaline pH regulator, water-swellable granular plugging agent and one-way pressure sealing agent into the above polymer solution, stirring until completely dissolved to obtain the high temperature resistant plugging agent.

[0061] The usage method of the leak-stopping agent provided by the embodiment of the present invention is as follows: the leak-stopping agent is prepared in the surface tank and transported to the formation where leakage occurs ...

Embodiment 1

[0068] This embodiment provides an anti-high temperature plugging agent, which includes the following components in mass percentage:

[0069] Polyacrylamide, 2%;

[0070] Sulfonated phenolic resin, 1%;

[0071] Water-swellable granular plugging agent, 5%;

[0072] Hexamethylenetetramine, 1%;

[0073] One-way pressure sealant, 5%;

[0074] Sodium hydroxide, 0.5%;

[0075] Water, 85.5%.

[0076] The preparation method of the anti-high temperature plugging agent is as follows: according to the above ratio, polyacrylamide is dissolved in water to obtain a polyacrylamide solution; sulfonated phenolic resin and hexamethylenetetramine are added to the above polyacrylamide solution, Stir until completely dissolved to obtain a polymer solution; add sodium hydroxide, water-absorbing swellable particle sealing agent and one-way pressure sealing agent to the above polymer solution, stir until completely dissolved to obtain the high temperature resistant plugging agent of this embodim...

Embodiment 2

[0079] This embodiment provides an anti-high temperature plugging agent, which includes the following components in mass percentage:

[0080] Polyacrylamide, 2.5%;

[0081] Sulfonated phenolic resin, 1.5%;

[0082] Water-swellable granular plugging agent, 3%;

[0083] Hexamethylenetetramine, 1.5%;

[0084] One-way pressure sealant, 3%;

[0085] Water, 88.5%.

[0086] The preparation method of the anti-high temperature plugging agent is the same as that in Example 1.

[0087] The anti-high temperature plugging agent does not undergo cross-linking reaction at room temperature, and does not form a gel. The apparent viscosity at room temperature is 116mPa·s, and the cross-linking reaction begins to occur at 120°C for 3 hours, and the colloid formed after standing for 8 hours The strength reaches the maximum. At this time, the viscosity of the colloid is 80206mPa s, the elastic modulus is 543.2Pa, and the viscous modulus is 104.1Pa. 2 After the core is plugged, the bearing pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Viscosity modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com