Ceramic aerogel and method for preparing the ceramic aerogel by gel injection moulding

A gel injection molding and aerogel technology, which is applied in the field of porous materials, can solve the problems of easy collapse and damage of pores, low heat resistance temperature, poor thermal insulation performance of porous materials, etc., and achieves excellent thermal insulation performance and high porosity. , the effect of good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

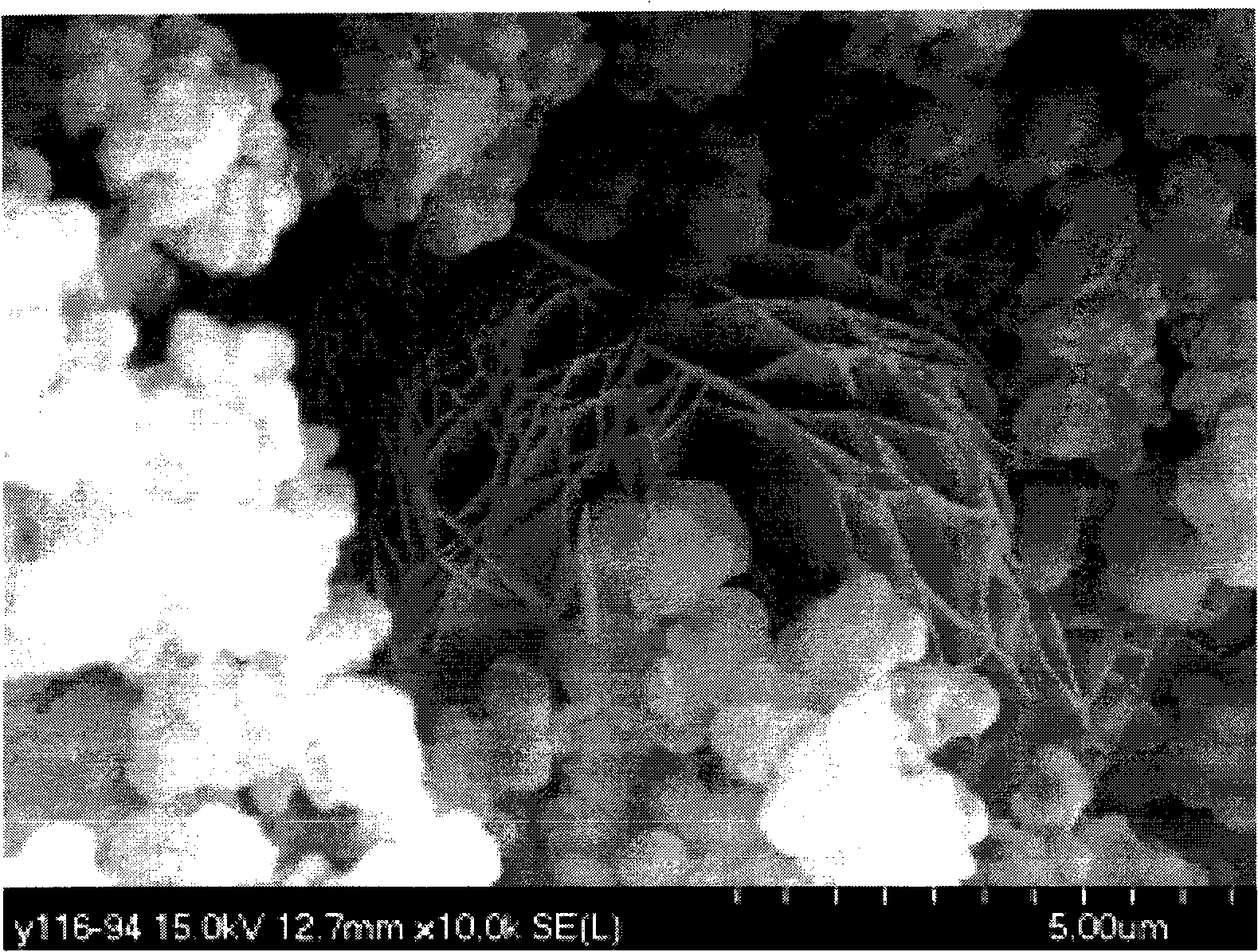

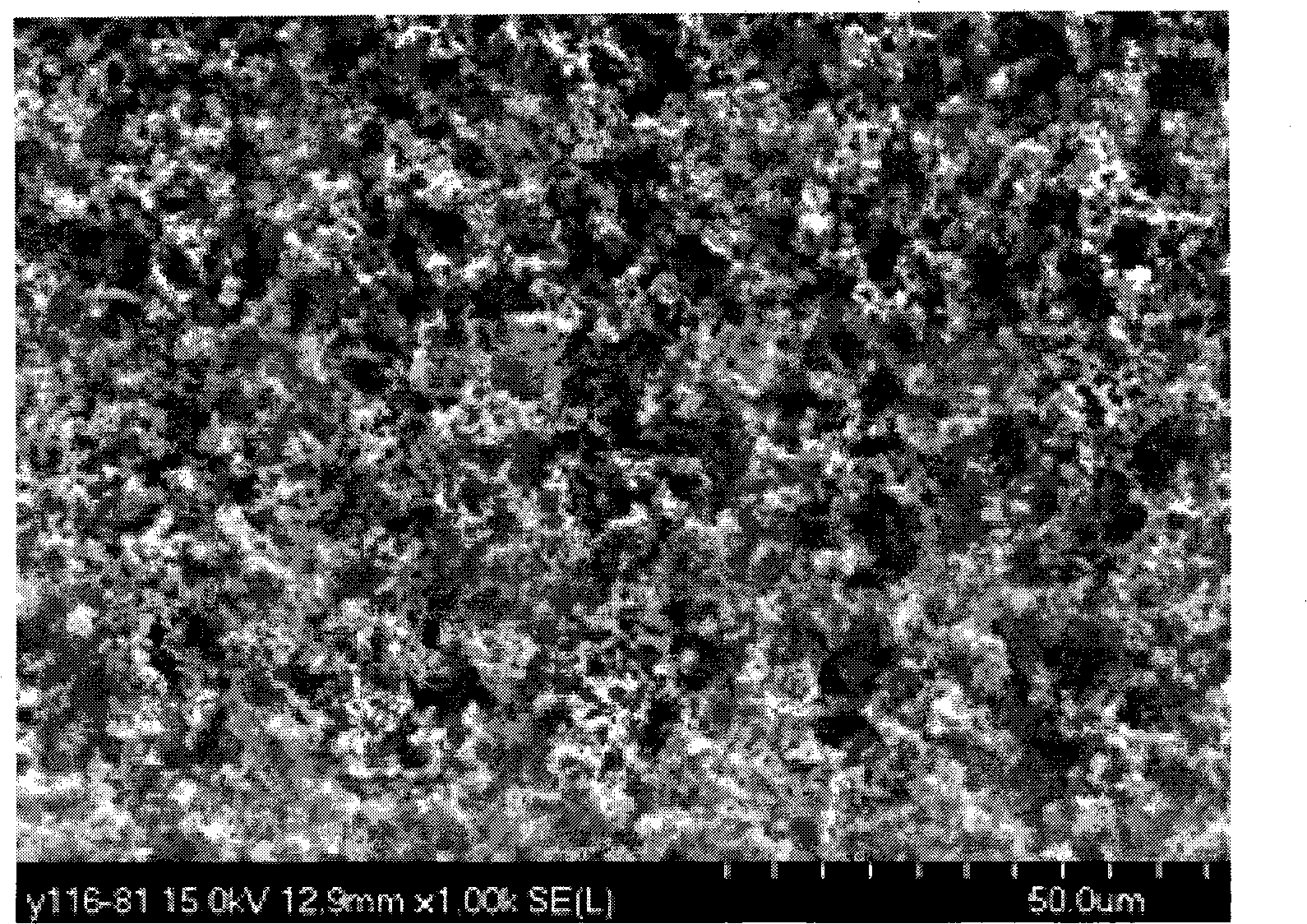

[0015] Specific Embodiment 1: In this embodiment, the ceramic airgel is composed of overlapping ceramic particles to form a three-dimensional skeleton structure, with a porosity of 50% to 90% (volume), and a micron-scale pore diameter, most likely below 3 μm.

[0016] The heat-resistant temperature of the ceramic airgel in this embodiment is 1000° C. to 3000° C., and the compressive strength is 1 to 50 MPa.

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the porosity of the ceramic airgel is 60% to 85% (volume). Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the porosity of the ceramic airgel is 65%-80% (volume). Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com