High-temperature-resistant antistatic adhesive tape and preparation method thereof

An anti-static, high-temperature-resistant technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of reducing the transparency of the cohesive strength tape, failing to play the role of anti-static, affecting the performance of adhesives, etc., to achieve excellent No adhesive residue after peeling, good antistatic effect, and no adhesive residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

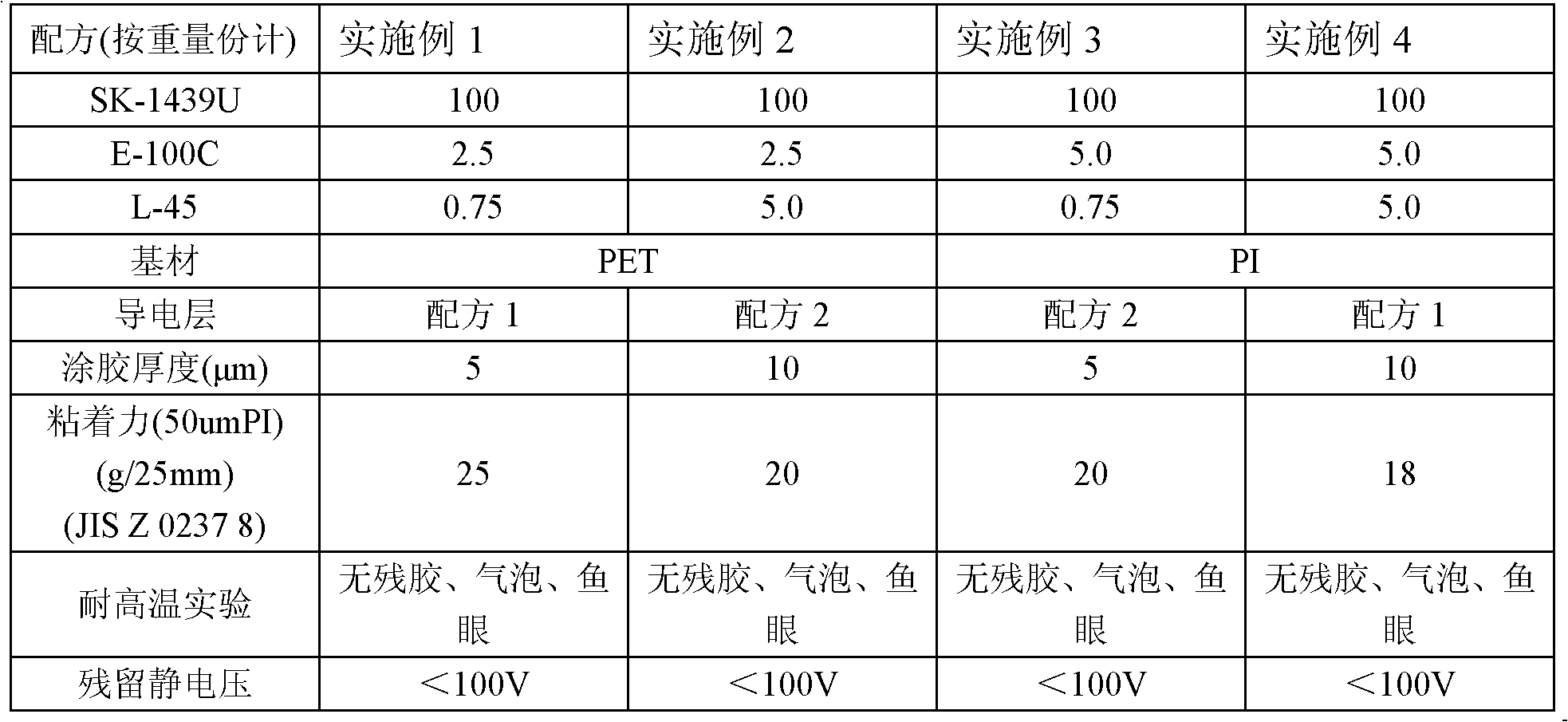

[0029] Below in conjunction with embodiment the present invention is described in further detail.

[0030] The preparation method of protective tape, comprises the steps:

[0031] ① Use one of PET, PI, and PEN as the substrate, and perform corona on the surface of the substrate to make the surface tension of the substrate ≥ 46 dynes. The corona conditions are preferably as follows: corona power 1.0KW ~ 2.0KW, running speed 10m / min;

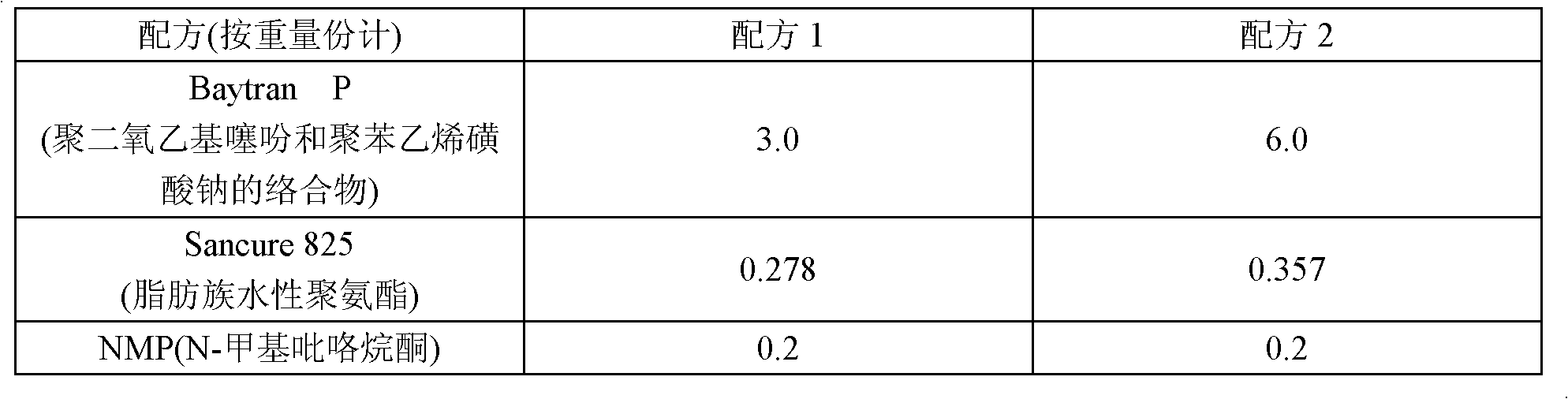

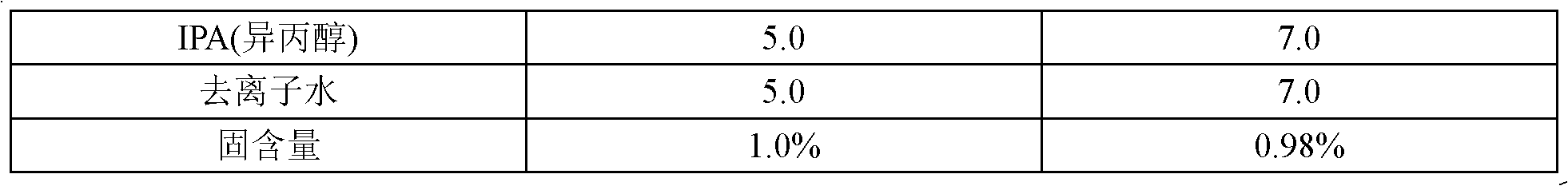

[0032] ②Coat the conductive layer mixed solution on one side of a 50 micron thick substrate (one of PET, PI, PEN) with a screen printing roller, and dry it in an oven. The length of the oven is 30m, and the coating speed is 50m / min. The temperature is 130°C, and the coating thickness is controlled at 0.1-0.5 microns;

[0033] ③Then apply acrylic adhesive on the conductive layer, put it into an oven for drying and pre-curing, the maximum temperature of the oven is 110°C, the thickness of the glue is 5-10 microns, the coating speed is 35m / min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com