High temperature resistant strippable anti-corrosive paint and preparation method thereof

A technology of anti-corrosion coating and high temperature resistance, applied in anti-corrosion coatings, coatings and other directions, can solve the problems of difficult to remove the coating film, damage to the surface, labor and time-consuming, etc. painted effect

Inactive Publication Date: 2009-03-18

DALIAN MARITIME UNIVERSITY

View PDF0 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The usual protective measure is to apply paint. In order to remove the paint film during use, organic solvents are often used to dissolve the paint film, treated with alkaline water, or treated with physical methods such as bamboo knives and scrapers. However, these methods are difficult to remove the paint film. And damage the surface, labor-intensive and time-consuming

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

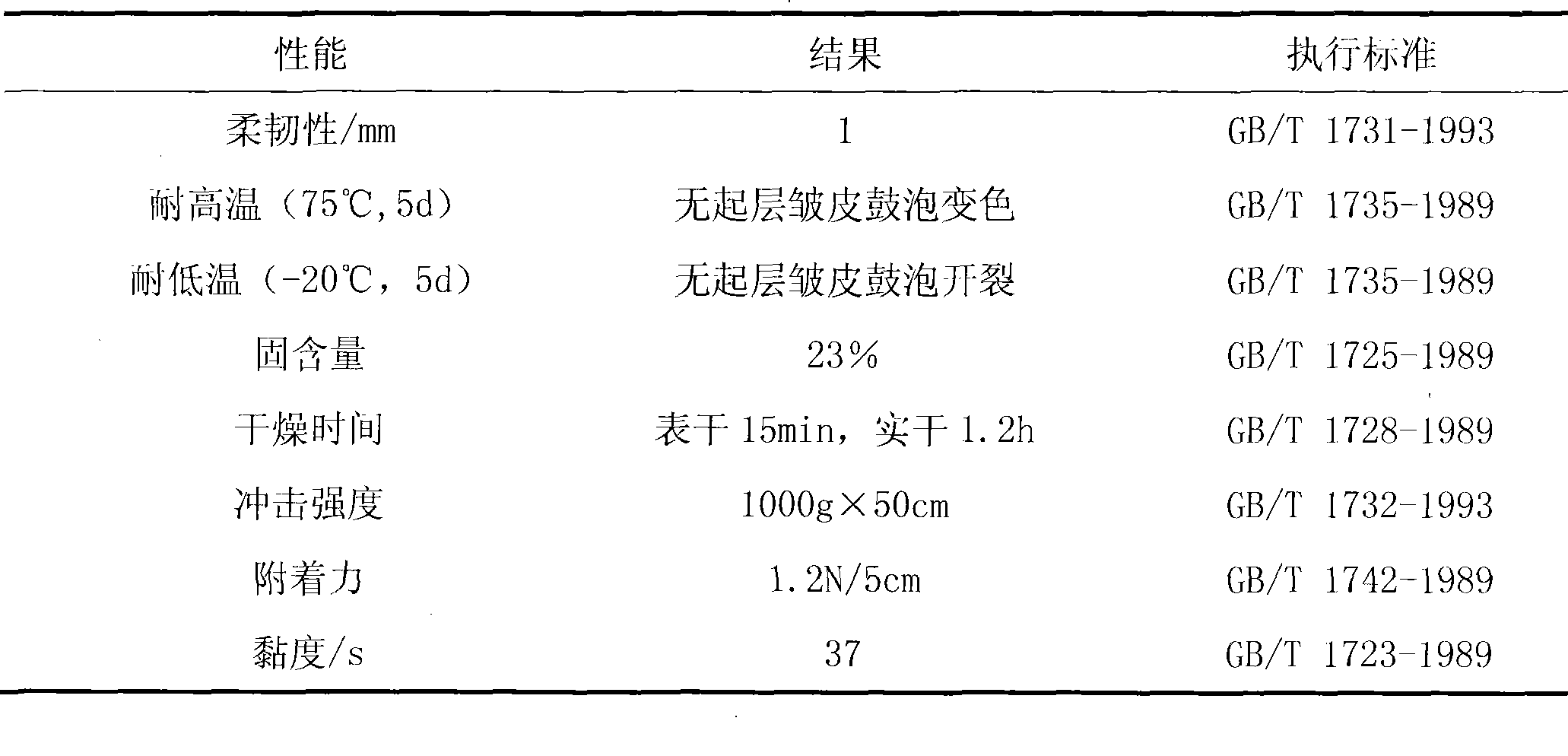

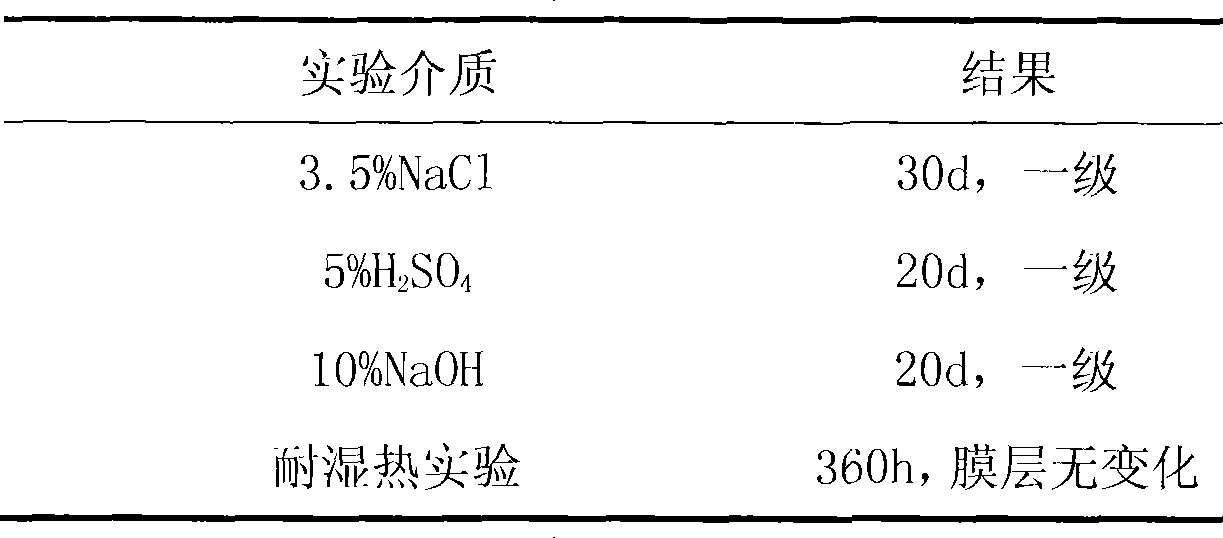

[0034] Select 15% of film-forming agent, 8% of auxiliary agent, and 77% of solvent, and stir at room temperature for 30 minutes to prepare a high-temperature-resistant peelable anti-corrosion coating. The results of its physical properties and corrosion resistance are shown in Table 1 and Table 2 below:

[0035] Table 1 Physical property results

[0036]

[0037] Table 2 Acid, alkali, salt immersion test results

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a special coating, in particular to a high temperature resistant strippable anti-corrosion coating and a preparation method thereof. The coating consists of a film forming agent, an auxiliary agent and a solvent, and the compositions in percentage by weight are as follows: 12 to 17 percent of the film forming agent, 5 to 10 percent of the auxiliary agent, and 73 to 83 percent of the solvent. The concrete preparation method comprises the following steps: the film forming agent, the auxiliary agent and the solvent are mixed according to the weight ratio, and then are stirred at normal temperature in a closed container to dissolve for 30 minutes to obtain a product. The coating takes a high molecular polymer as a film forming material, has the advantages of good acid, base and salt resistances, excellent toughness, remarkable high temperature resistance, easiness for coating, convenient unsealing, and no pollution to the surface of metal after a solidified coating film is stripped; in addition, the stripped coating film can be repeatedly used after the treatment.

Description

technical field [0001] The invention relates to a special paint, in particular to a high-temperature-resistant peelable anti-corrosion paint and a preparation method thereof. Background technique [0002] Corrosion of metal materials is most common in atmospheric environments, especially in some high-temperature environments. The usual protective measure is to apply paint. In order to remove the paint film during use, organic solvents are often used to dissolve the paint film, treated with alkaline water, or treated with physical methods such as bamboo knives and scrapers. However, these methods are difficult to remove the paint film. And damage the surface, labor-intensive and time-consuming. Contents of the invention [0003] The purpose of the present invention is to overcome the shortcomings of traditional coatings and provide a high temperature-resistant strippable anti-corrosion coating. [0004] The technical scheme of the present invention is: the high temperatur...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09D157/00C09D153/02C09D5/08C09D5/20

Inventor 梁成浩王兴飞黄乃宝

Owner DALIAN MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com