EPDM series environment-friendly type rubber floor sizing material and preparing method thereof

A technology of EPDM rubber and EPDM, which is applied in the preparation of EPDM series of environmentally friendly rubber floor rubber materials, and in the field of EPDM series of environmentally friendly rubber floor materials, can solve the problem of inelasticity and price Expensive, water-resistant and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

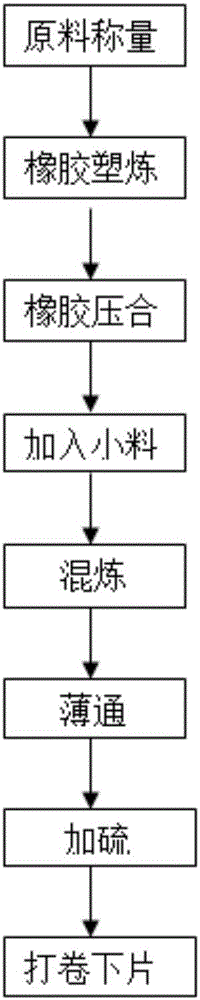

[0030]The preparation method of EPDM series environment-friendly rubber floor rubber materials adopts an open rubber mixing machine, such as figure 1 As shown, the specific steps are as follows:

[0031] Step 1. Weigh raw materials, weigh EPDM rubber 29%-32%, zinc oxide 1.4%-1.6%, active magnesium oxide 1.1%-1.3%, stearic acid 0.2%-0.35%, environmental protection Antioxidant 445 0.4%~0.5%, titanium dioxide 1.4%~3.2%, clay 0~6.5%, flame retardant FR-880 12%~18.5%, aluminum hydroxide 18%~23.5%, zinc borate 4%~ 6.5%, flame retardant BN-18C 0~4.6%, white carbon black 4%~6.5%, nano kaolin 0~7.6%, superfine calcium carbonate 0~6.5%, antistatic agent 0.5%~0.65%, dispersant FC-303 0.5%~0.65%, flow aid PEG4000 0.5%~0.65%, anti-ultraviolet agent UV-531 0.4%~0.5%, antibacterial agent CZ-KZ100.4%~0.5%, deodorant JH-100A0. 5%~0.7%, odorless DCP 0.7%~0.85%, vulcanizing agent PDM 0.4%~0.5%, pigment 0~0.2%, the total content percentage of the above components is 100%;

[0032] Step 2, mast...

Embodiment 1

[0044] The preparation method of EPDM series environment-friendly rubber floor compound is specifically implemented according to the following steps:

[0045] Step 1. Weigh the raw materials, and weigh 31.53% of EPDM rubber, 1.58% of zinc oxide, 1.26% of active magnesium oxide, 0.32% of stearic acid, 0.47% of environmentally friendly anti-aging agent 445, 3.15% of titanium dioxide, Clay 6.31%, flame retardant FR-880 12.61%, aluminum hydroxide 18.92%, zinc borate 6.31%, white carbon black 6.31%, superfine calcium carbonate 6.31%, antistatic agent 0.63%, dispersant FC-303 0.63% , flow aid PEG4000 0.63%, anti-ultraviolet agent UV-531 0.47%, antibacterial agent CZ-KZ10 0.47%, deodorant JH-100A 0.63%, odorless DCP 0.85%, vulcanizing agent PDM 0.47%, pigment 0.16%, above The sum of the content percentages of components is 100%;

[0046] Step 2, plasticizing the EPDM rubber weighed in step 1: the roller distance is controlled at 2mm, and the time is controlled at 6min;

[0047] Ste...

Embodiment 2

[0054] The preparation method of EPDM series environment-friendly rubber flooring compound adopts an open rubber mixing machine, and is specifically implemented according to the following steps:

[0055] Step 1. Weigh the raw materials, and weigh 29.22% of EPDM rubber, 1.46% of zinc oxide, 1.17% of activated magnesium oxide, 0.29% of stearic acid, 0.44% of environmentally friendly anti-aging agent 445, 1.46% of titanium dioxide, Clay 4.38%, flame retardant FR-880 14.61%, aluminum hydroxide 23.38%, zinc borate 4.38%, flame retardant BN-18C 4.38%, white carbon black 4.38%, nano kaolin 5.84%, antistatic agent 0.58%, Dispersant FC-303 0.58%, flow aid PEG40000.58%, anti-ultraviolet agent UV-531 0.44%, antibacterial agent CZ-KZ10 0.44%, deodorant JH-100A 0.58%, odorless DCP 0.79%, vulcanizing agent PDM 0.44%, pigment 0.15%, the sum of the content percentages of the above components is 100%;

[0056] Step 2, plasticizing the EPDM rubber weighed in step 1: the roller distance is cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com