Anti-haze green mouth mask based on oxidized graphene and manufacturing method

A technology of graphene and masks, which is applied in the field of green antibacterial and anti-haze masks based on graphene oxide and its preparation, which can solve the problems of inability to absorb dust, antibacterial, deodorizing, insufficient compounding of antibacterial agents, and complicated preparation processes, etc. problems, to achieve the effect of good dust adsorption performance, excellent deodorization, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

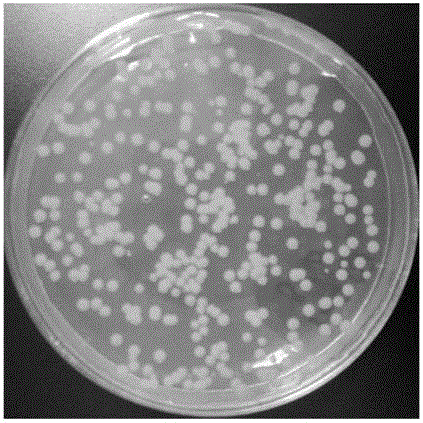

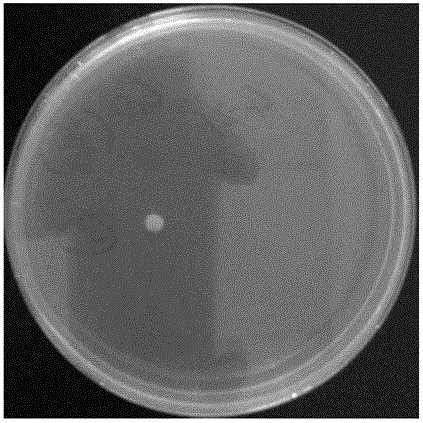

[0037] Mix graphene oxide, tannic acid, and silver nitrate in a 0.2M sodium hydroxide solution at a mass ratio of 1:10:0.2, and then react at 80°C for 1 hour in the dark to prepare the green antibacterial material graphene oxide-tannic acid - Nanosilver.

[0038]A water mixture of green antibacterial material graphene oxide-tannic acid-nanosilver was prepared with a concentration of 50 μg / mL. Then use compressed air to spray the antibacterial mixed solution on the non-woven fabric, the average spraying amount is 0.03mL / cm 2 .

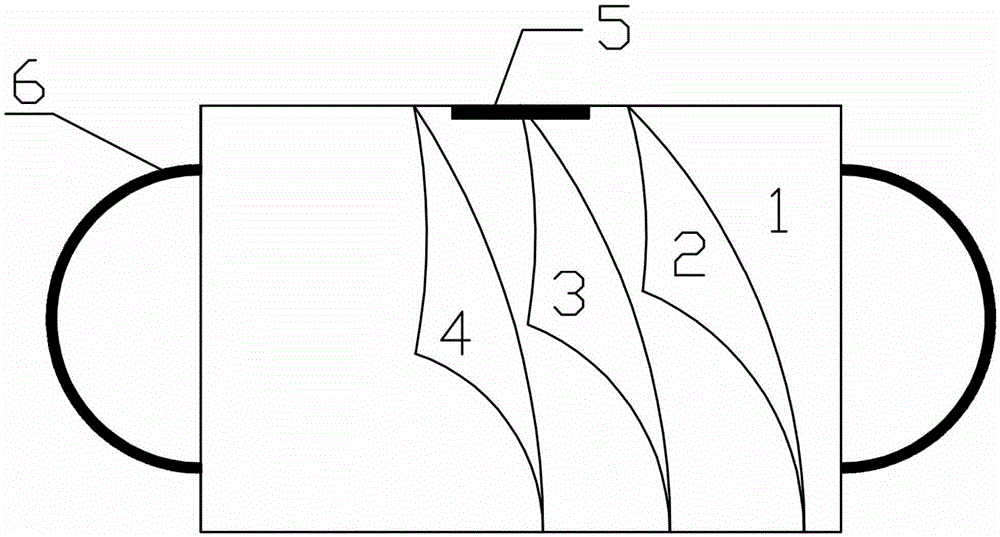

[0039] Arrange the sprayed non-woven fabric inside the mask, and place it on the second layer from the layer close to the mouth, where the sol non-woven fabric layer is the third layer from the layer close to the mouth, close to the mouth and the outermost The layers are high-quality protective non-woven fabrics.

Embodiment 2

[0041] Mix graphene oxide, tannic acid, and silver nitrate in a 0.5M sodium hydroxide solution at a mass ratio of 1:30:0.2, and then react at 100°C in the dark for 5 hours to prepare the green antibacterial material graphene oxide-tannic acid - Nanosilver.

[0042] A water mixture of green antibacterial material graphene oxide-tannic acid-nanosilver with a concentration of 500 μg / mL was prepared. Then use compressed air to spray the antibacterial mixed solution on the non-woven fabric, the average spraying amount is 1mL / cm 2 .

[0043] Arrange the sprayed non-woven fabric inside the mask, and place it on the third layer from the layer close to the mouth, where the sol non-woven layer is the second layer from the layer close to the mouth, close to the mouth and the outermost The layers are high-quality protective non-woven fabrics.

Embodiment 3

[0045] Mix graphene oxide, tannic acid, and silver nitrate in 0.3M sodium hydroxide solution at a mass ratio of 1:20:0.2, and then react at 90°C for 2 hours in the dark to prepare the green antibacterial material graphene oxide-tannic acid - Nanosilver.

[0046] A water mixture of green antibacterial material graphene oxide-tannic acid-nanosilver was prepared with a concentration of 150 μg / mL. Then use compressed air to spray the antibacterial mixed solution on the non-woven fabric, the average spraying amount is 0.5mL / cm 2 .

[0047] Arrange the sprayed non-woven fabric inside the mask, and place it on the second layer from the layer close to the mouth, where the sol non-woven fabric layer is the third layer from the layer close to the mouth, close to the mouth and the outermost The layers are high-quality protective non-woven fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com