Sand textured two-component plaster mortar composition

A plastering mortar, two-component technology, applied in the field of construction mortar, to achieve the effects of good light and weather resistance, enhanced cohesion, and enhanced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

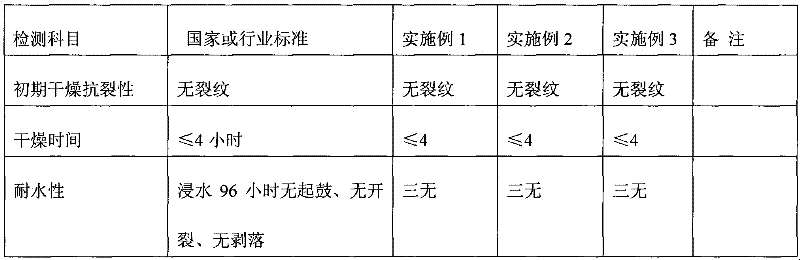

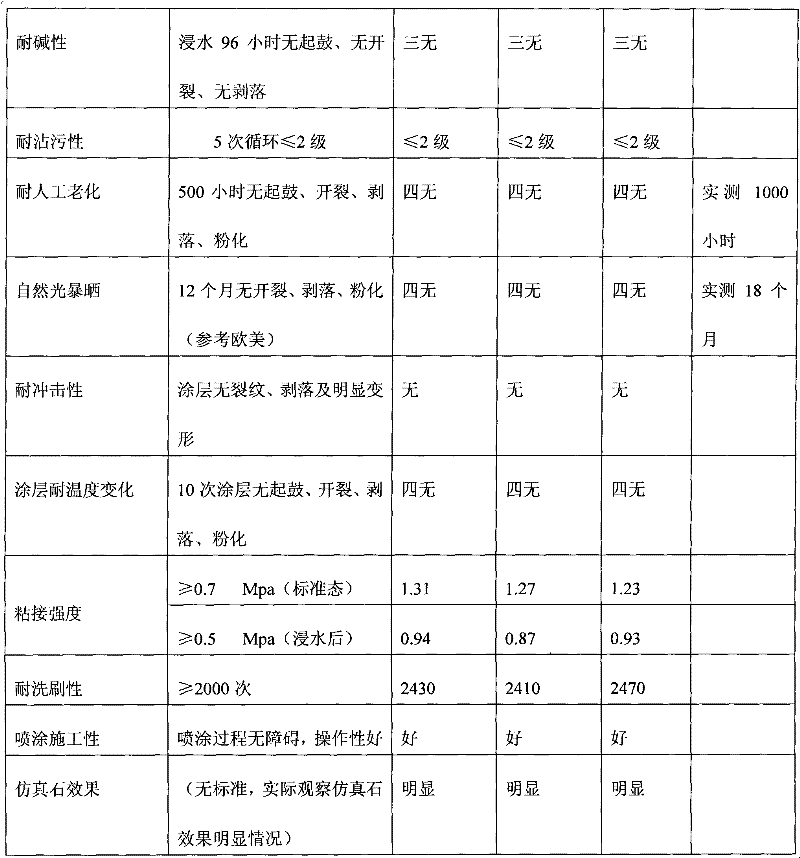

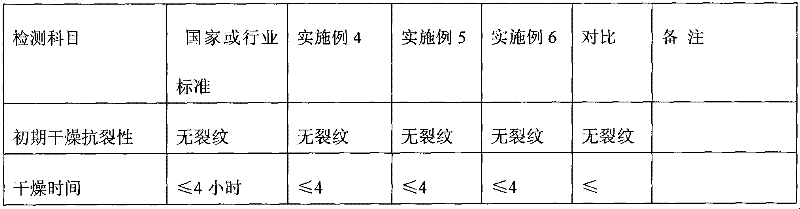

Examples

Embodiment 1

[0035] 20 parts of white cement, 60 parts of corundum, 0.5 parts of gelatin powder, 0.3 parts of xanthan gum, 0.1 part of hydroxyethyl cellulose ether, 3 parts of lithopone, 0.1 part of magnesium fluorosilicate, 1.5 parts of polytetrafluoroethylene micropowder , 0.1 part of sodium tripolyphosphate, 0.1 part of defoamer, 40 parts of modified polyurethane emulsion, and 1 part of dipropylene glycol methyl ether.

[0036] At room temperature, add white cement, carborundum, cellulose ether, lithopone, flame retardant, sodium tripolyphosphate, hardener and defoamer into the mixer and stir evenly. Before use, add modified Polyurethane Emulsion and Dipropylene Glycol Methyl Ether.

[0037] The preparation method of described modified polyurethane emulsion is as follows:

[0038] (1) Heat 100 parts by weight of silica powder to 110°C, spray 2 parts by weight of molten polyethylene wax on the silica powder, and after mixing, spray 3 parts by weight of glycidoxypropyl Coupling of trime...

Embodiment 2

[0046] 22 parts of white cement, 55 parts of corundum, 0.7 parts of gelatin powder, 0.3 parts of xanthan gum, 0.15 parts of hydroxyethyl cellulose ether, 4 parts of lithopone, 0.2 parts of magnesium fluorosilicate, 2 parts of polytetrafluoroethylene micropowder , 0.2 parts of sodium tripolyphosphate, 0.2 parts of defoamer, 42 parts of modified polyurethane emulsion, and 1.5 parts of dipropylene glycol methyl ether.

[0047] At room temperature, add white cement, carborundum, cellulose ether, lithopone, flame retardant, sodium tripolyphosphate, hardener, P803 defoamer into the mixer and stir evenly, then add modified Polyurethane Emulsion and Dipropylene Glycol Methyl Ether.

[0048] The preparation method of described modified polyurethane emulsion is as follows:

[0049] (1) Heat 100 parts by weight of silica powder to 110°C, spray 3 parts by weight of molten polyethylene wax on the silica powder, and after mixing, spray 4 parts by weight of glycidoxypropyl Coupling of trim...

Embodiment 3

[0057] 24 parts of white cement, 50 parts of corundum, 0.9 parts of gelatin powder, 0.25 parts of xanthan gum, 0.2 parts of hydroxyethyl cellulose ether, 5 parts of lithopone, 0.3 parts of magnesium fluorosilicate, 2.5 parts of polytetrafluoroethylene powder , 0.3 parts of sodium tripolyphosphate, 0.3 parts of defoamer, 44 parts of modified polyurethane emulsion, and 2 parts of dipropylene glycol methyl ether.

[0058] At room temperature, add white cement, carborundum, cellulose ether, lithopone, flame retardant, sodium tripolyphosphate, hardener, P803 defoamer into the mixer and stir evenly, then add modified Polyurethane Emulsion and Dipropylene Glycol Methyl Ether.

[0059] The modified polyurethane emulsion was prepared by the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com