Powder coating containing nano whisker material and preparation method thereof

A nano-whisker, powder coating technology, applied in powder coatings, polyester coatings, epoxy resin coatings, etc., achieves the effects of reducing production costs, expanding the scope of use, and simple and efficient preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

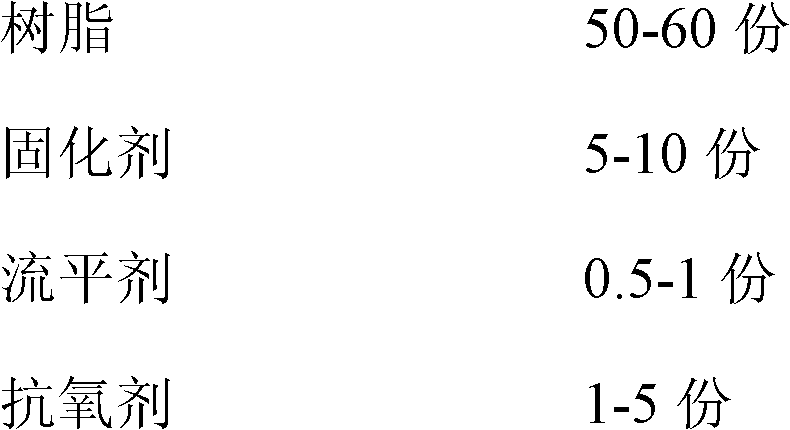

Embodiment 1

[0028] (1) Add the Si-69 coupling agent of 1g in 499g nano barium sulfate whisker, mix at a high speed at 50 DEG C, obtain the modified nano barium sulfate whisker after stirring;

[0029] Nano-barium sulfate whiskers have an average diameter of 50nm and an average length of 200μm;

[0030] (2) 500g mixture in step (1), polyester of 600g, 50g triglycidyl isocyanurate, 5g acrylate, 10g antioxidant 1010, 2g benzylethanol ketone, 40g aluminum stearate are mixed Mix evenly in the machine;

[0031] (3) Extruding the mixture containing the nano whisker material in step (2) at 120° C., then crushing, grading and sieving to obtain the nano whisker powder coating immediately.

[0032] Paint film performance:

[0033]

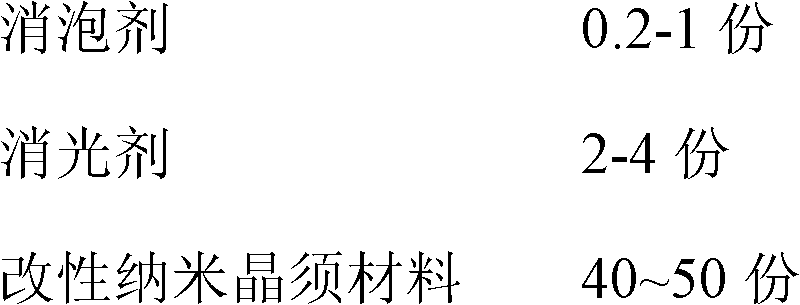

Embodiment 2

[0035] Adopt the same method as embodiment 1, wherein:

[0036] (1) at first 2600g nano-calcium sulfate whiskers and 2600g nano-calcium carbonate whiskers are mixed, add the stearic acid coupling agent of 600g in, mix at 105 ℃, stir, obtain the nano-whisker material of modification after;

[0037] Nano-barium sulfate whiskers have an average diameter of 100nm and an average length of 30μm;

[0038] The average diameter of nano-calcium carbonate whiskers is 60nm, and the average length is 175μm;

[0039] (2) 6000g mixture in step (1), epoxy resin of 5000g, 1000g hydroxyalkyl amide, 100g polysiloxane, 500g antioxidant 264, 100g benzylethanol ketone, 200g silicon dioxide in mixer well mixed;

[0040] (3) Extrude the mixture containing the nano whisker material in step (2) at 105° C., then crush and classify and sieve to obtain the nano whisker powder coating immediately.

[0041] Paint film performance:

[0042]

[0043]

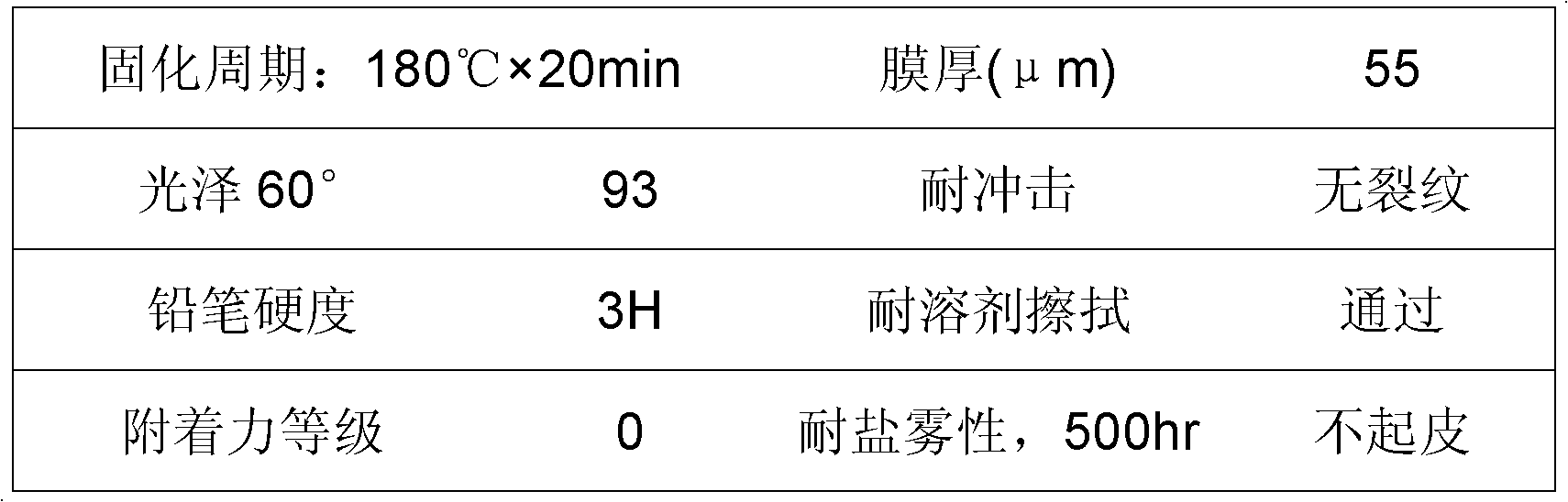

Embodiment 3

[0045] Adopt the same method as embodiment 1, wherein:

[0046] (1) Add the Si-69 coupling agent of 9g in 450g nano barium sulfate whisker, mix at 50 ℃, obtain the modified nano whisker material after stirring;

[0047] Nano-barium sulfate whiskers have an average diameter of 75nm and an average length of 100μm;

[0048] (2) The mixture of 459g in step (1), the polyester of 550g, 80g hydroxyalkyl amide, 9g acrylate, 25g antioxidant 264, 7g benzylethanolone, 28g zinc stearate are mixed in mixer ;

[0049] (3) Extrude the mixture containing the nano whisker material in step (2) at 105° C., then crush and classify and sieve to obtain the nano whisker powder coating immediately.

[0050] Paint film performance:

[0051]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com