Tearing-resistant silicone rubber composition

A silicone rubber composition and tear-resistant technology, applied in the field of polymer materials, can solve the problems of poor physical and mechanical properties, poor mechanical properties such as tensile strength and tear strength, and poor oil resistance and solvent resistance. Achieve excellent mechanical properties and outstanding tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

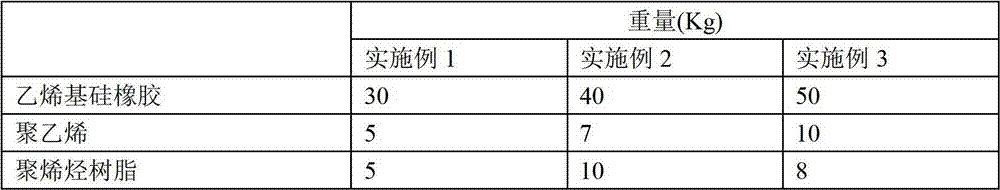

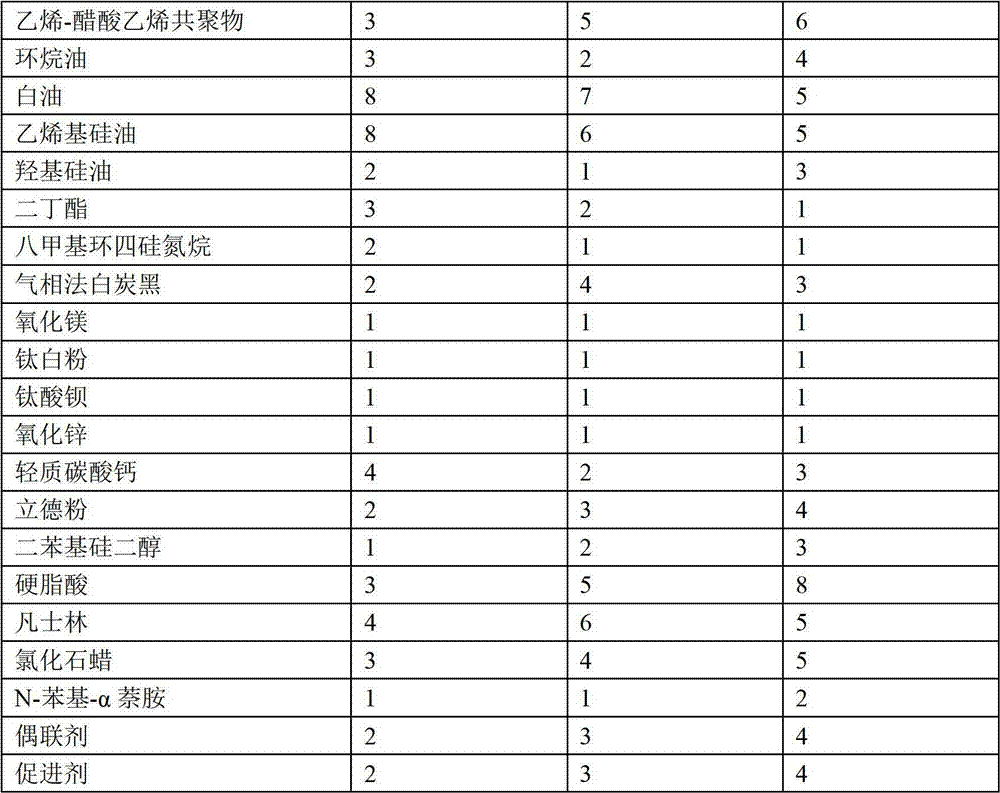

[0017] The components were prepared in the weight ratios shown in Table 1.

[0018] The weight proportion of table 1 embodiment 1~embodiment 3

[0019]

[0020]

[0021] The above-mentioned accelerator adopts dibenzothiazole disulfide.

[0022] The above-mentioned fumed white carbon black adopts No. 4 fumed white carbon black.

[0023] The above-mentioned coupling agent adopts silane coupling agent KH-550.

[0024] The preparation method is as follows:

[0025] S1: Mix vinyl silicone rubber, polyethylene, polyolefin resin, ethylene-vinyl acetate copolymer, and two-roll mill for 5 to 10 minutes, add naphthenic oil, white oil, vinyl silicone oil, hydroxyl silicone oil, Butyl ester, octamethylcyclotetrasilazane, mixed evenly;

[0026] S2: Add fumed silica, diphenylsilanediol, stearic acid, petrolatum, chlorinated paraffin, N-phenyl-α-naphthylamine, coupling agent, accelerator, and knead for 20 to 30 minutes;

[0027] S3: add magnesium oxide, titanium dioxide, barium ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com