Antiskid paint for bicycle court tracks and preparation method thereof

A technology for anti-skid coatings and bicycles, applied in the field of coating materials, can solve the problem that water resistance and wear resistance cannot be satisfied at the same time, and achieve the effects of good anti-skid effect, good wear resistance and excellent water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

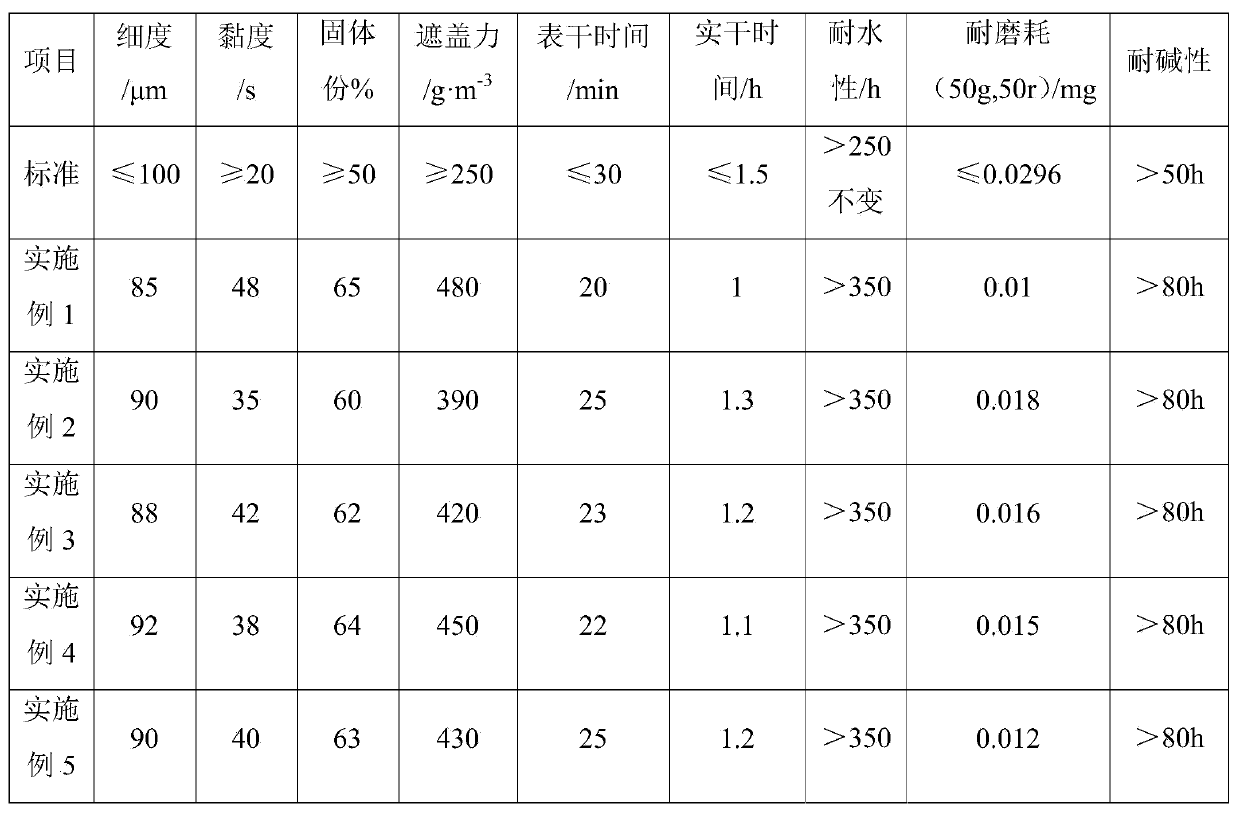

Examples

Embodiment 1

[0017] A kind of non-slip coating for the track of a bicycle racing field, comprising the components of the following parts by weight: 32 parts of polyurethane emulsion, 7 parts of light calcium carbonate, 6 parts of titanium dioxide, 3.5 parts of phenolic resin, 6.5 parts of talcum powder, hollow glass microspheres ( 9 parts of 200 mesh), 9 parts of rubber particles (200 mesh), 0.9 parts of triester phosphite (2,4-di-tert-butylphenyl), 11 parts of lithopone, 0.29 parts of defoamer (BYK-055) and 40 parts of water. Mix the above components and stir for 5 hours at 25°C at a speed of 100r / min.

Embodiment 2

[0019] An anti-slip coating for a bicycle racing track, comprising the following components in parts by weight: 30 parts of styrene-acrylic emulsion, 8 parts of light calcium carbonate, 5 parts of titanium dioxide, 4 parts of phenolic resin, 6 parts of talcum powder, and hollow glass microspheres (200 mesh) 20 parts, 4,4'-thiobis(6-tert-butyl-3-methylphenol) 1.0 parts, lithopone 11 parts, defoamer (BYK-055) 0.3 parts and water 42 share. Mix the above components and stir for 5 hours at 28°C at a speed of 100r / min to obtain the obtained product.

Embodiment 3

[0021] An anti-slip coating for a bicycle track, comprising the following components in parts by weight: 35 parts of silicon acrylic emulsion, 6 parts of light calcium carbonate, 8 parts of titanium dioxide, 4 parts of polytrifluorochloroethylene, 7 parts of talcum powder, rubber 20 parts of particles (200 mesh), 0.8 parts of β-(3,5-tertiary butyl-4-hydroxyphenyl) octadecyl propionate, 12 parts of lithopone, defoamer (BYK-055) 0.25 parts and 38 parts water. Mix the above components and stir for 5 hours at 28°C at a speed of 100r / min to obtain the obtained product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com