Titanium white for dry acrylic spinning delustering its preparing method

A dry-process acrylic fiber and titanium dioxide technology, applied in the field of chemical fiber titanium dioxide, can solve the problems of undiscovered patent reports and rare patents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

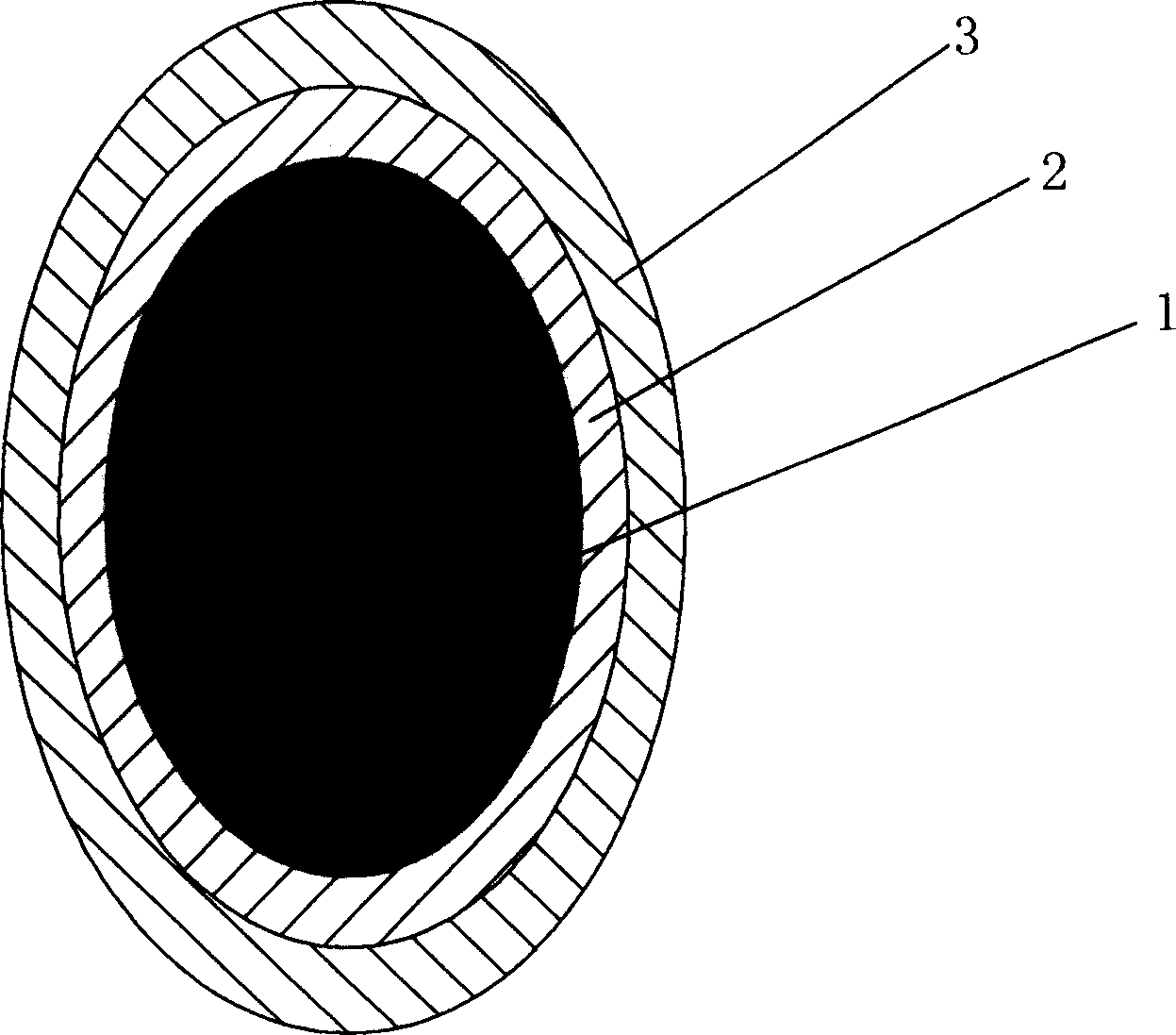

Image

Examples

Embodiment 1

[0077] Add 3500g of deionized water into a 5L glass beaker, anatase TiO 2 2500g, beating and dispersing for 30 minutes with mechanical stirring, then sand milling for 2 hours in a sand mill filled with zirconia grinding beads, and dilute the resulting slurry with 5L deionized water, carry out sedimentation classification in a gravity settler, remove the bottom containing For the coarse particle slurry, the upper layer (90%) slurry is taken for subsequent use.

[0078] In a 10L jacketed reactor equipped with a stirrer, reflux condenser, high-level feed tank and temperature display, add 5L of the above-mentioned upper layer slurry and heat to 65°C. At the same time, 335 g of 15% aluminum sulfate solution and 300 g of 10% sodium hydroxide solution were added dropwise to the reaction kettle at a constant speed, and the addition was completed in 7 hours, and the mixture was kept for 4 hours for aging. Cool to below 35°C, adjust the pH value of the slurry to 7.0 with 5% sulfuric a...

Embodiment 2

[0081] at 5m 3 Add 3500L of deionized water into the stainless steel cylindrical tank, anatase TiO 2 2500kg, beating and dispersing for 2 hours with mechanical stirring, and then sanding for 3 hours in a sand mill filled with zirconia grinding beads, the resulting slurry was used for 5m 3 Dilute with deionized water, classify in a spiral centrifugal classifier, remove the thick slurry containing coarse particles, and take the dispersed thin slurry for later use.

[0082] In the 10m equipped with stirrer, reflux condenser, high feed tank and temperature display 3 In the reaction kettle, add the above graded slurry 7m 3 , heated to 95°C. At the same time, 470 kg of 10% sodium aluminate solution and 270 kg of 10% sulfuric acid solution were added dropwise to the reaction kettle at a uniform speed, and the addition was completed in 5 hours, and then aged for 2 hours. Cool to below 35°C, adjust the pH value of the slurry to 6.0 with 5% sulfuric acid solution and 5% sodium hydr...

Embodiment 3

[0085] Front operation is the same as embodiment 1. The organic treatment agent was replaced with: 2g of pentaerythritol, 1g of isopropyl tris(dioctylpyrophosphoryloxy) titanate, 0.3g of diisobutyl phthalate, and 5g of sodium polymethacrylate. Stir at 10°C for 1 hour, dry in an oven, and pulverize with a jet mill. The obtained titanium dioxide has good whiteness and light fastness. After the 10% DMF dispersion is sand-milled for 50 minutes, it takes 80 seconds to vacuum filter 50 ml of it with 9 cm qualitative filter paper. The titanium dioxide prepared by the above method is applied to the matting of the dry-process acrylic fiber system, has good filtration performance and spinnability, low end breakage rate, and the obtained tow has high strength, high whiteness and good dyeability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com