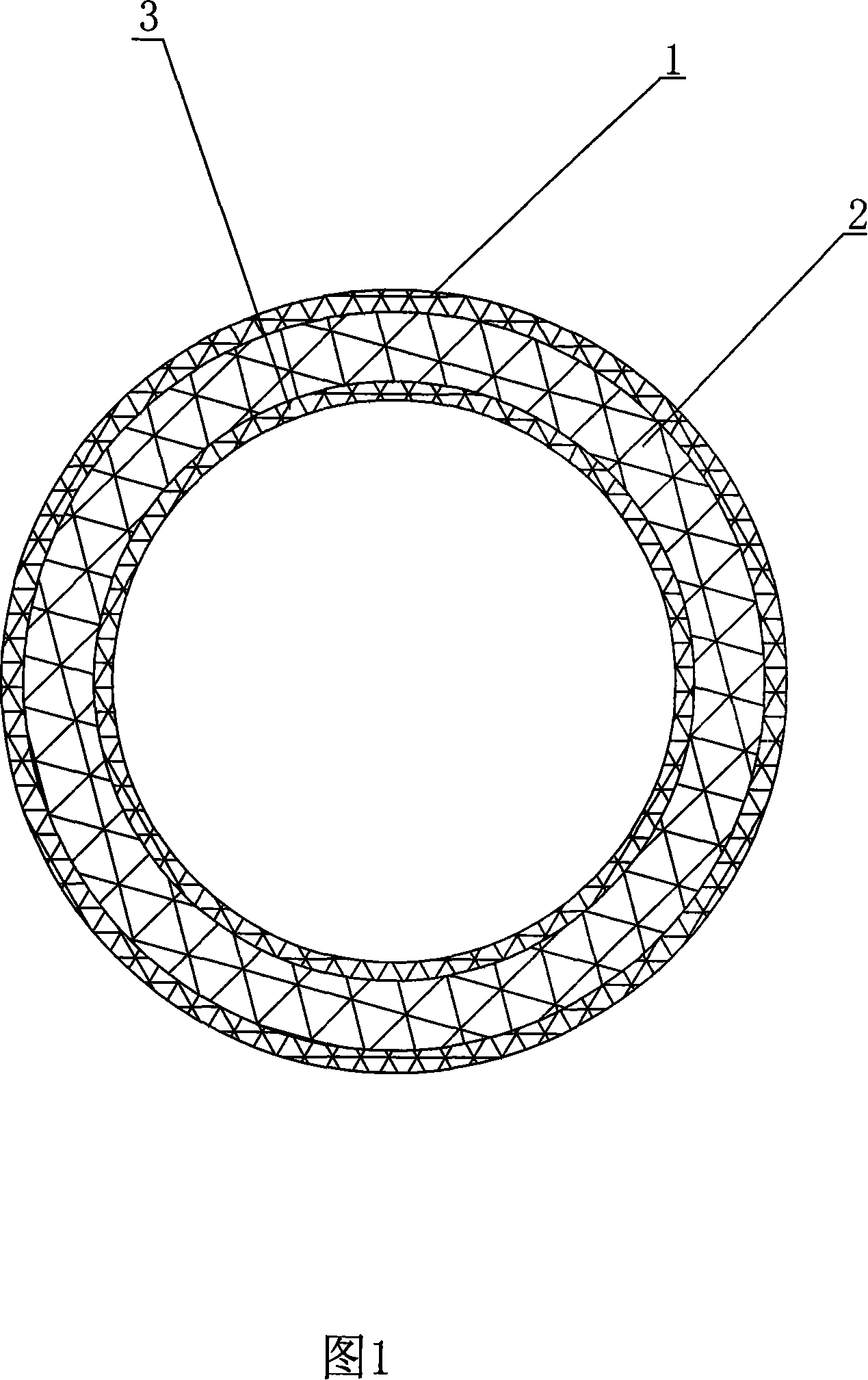

PVC-U composite nano drainpipe manufacturing method

A production method and drainage pipe technology, applied in the direction of pipes, rigid pipes, layered products, etc., can solve physical and chemical properties such as strength, toughness, corrosion resistance, heat resistance, general strength, toughness, corrosion resistance, Poor physical and chemical properties such as heat resistance, rough internal and external finish, etc., to achieve the effect of ensuring strength and performance, reducing production costs, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A. First prepare the materials for the inner and outer layers according to the following raw material proportions in parts by weight:

[0026] PVC resin 80 ordinary calcium carbonate 10 nanometer calcium carbonate 4 PVC composite stabilizer 2

[0027] PE wax 0.4 stearic acid 0.3 titanium dioxide 0.8 ACR 1.1

[0028] Described core layer material is according to the raw material ratio of following parts by weight:

[0029] Recycled PVC recycled material 80 Ordinary calcium carbonate 8 Nano calcium carbonate 4

[0030] PVC composite stabilizer 3 PE wax 0.3 stearic acid 0.3 titanium dioxide 0.8 ACR 0.8

[0031] B. Put the prepared raw materials for making the inner and outer layer materials and the materials for making the core layer into No. 1 and No. 2 high-low mixing units SHR respectively, first perform high-speed mixing and then low-speed mixing, and input No. 1 and No. 2 plastic powder respectively Foam feeder ETF.

[0032] C. First heat the conical twin-screw ex...

Embodiment 2

[0035] A. First prepare the materials for the inner and outer layers according to the following raw material proportions in parts by weight:

[0036] PVC resin 90 ordinary calcium carbonate 30 nanometer calcium carbonate 4 PVC composite stabilizer 2.5 PE

[0037] Wax 0.6 Stearic Acid 0.6 Titanium Dioxide 1.2 ACR 1.5

[0038] Described core layer material is according to the raw material ratio of following parts by weight:

[0039] Recycled PVC recycled material 85 Ordinary calcium carbonate 20 Nano calcium carbonate 6

[0040] PVC composite stabilizer 5 PE wax 0.5 stearic acid 0.7 titanium dioxide 1.2 ACR 1.4

[0041] B. Put the prepared raw materials for making the inner and outer layer materials and the materials for making the core layer into No. 1 and No. 2 high-low mixing units SHR respectively, first perform high-speed mixing and then low-speed mixing, and input No. 1 and No. 2 plastic powder respectively Foam feeder ETF.

[0042] C. First heat the conical twin-screw...

Embodiment 3

[0045] A. First prepare the materials for the inner and outer layers according to the following raw material proportions in parts by weight:

[0046] PVC resin 120 ordinary calcium carbonate 40 nanometer calcium carbonate 8 PVC composite stabilizer 6

[0047] PE Wax 1.2 Stearic Acid 1.0 Titanium Dioxide 2.5 ACR 3.5

[0048] Described core layer material is according to the raw material ratio of following parts by weight:

[0049] Recycled PVC recycled material 110 through calcium carbonate 40 nanometer grade calcium carbonate 9

[0050]PVC composite stabilizer 6 PE wax 1.1 stearic acid 0.9 titanium dioxide 2.4 ACR 3.5

[0051] B. Put the prepared raw materials for making the inner and outer layer materials and the materials for making the core layer into No. 1 and No. 2 high-low mixing units SHR respectively, first perform high-speed mixing and then low-speed mixing, and input No. 1 and No. 2 plastic powder respectively Foam feeder ETF.

[0052] C. First heat the conical t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com