High transparency bright spandex yarn and its preparation method

A high-transparency, spandex yarn technology, applied in the direction of single-component polyurethane rayon filament, can solve the problems of chain extender affecting the uniformity and transparency of spandex yarn, performance limitations such as anti-aging and dyeing, and defects in physical and chemical properties of matte yarn. , to achieve excellent dyeing performance, good appearance, and improve the effect of textile structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail below in combination with embodiments.

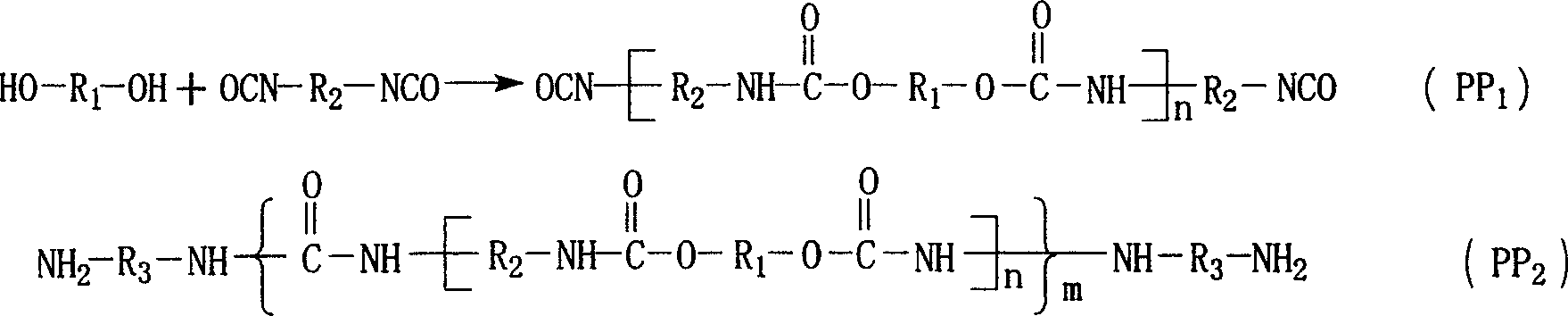

[0009] According to the theory of polymer crystallization, only amorphous or random polymers can be transparent, and crystalline copolymers, due to the existence of crystalline regions and amorphous regions, the refractive index of light to these two phases is always different, so crystalline polymerization Objects are often opaque. For polyurethane elastic fibers, it is composed of soft segments of a longer continuous phase and aggregated hard segments. Since the hard segments are easy to form crystals, it will inevitably affect the optical transparency of polyurethane elastic fibers. To solve this key problem, it is necessary to start from the molecular structure. On the basis of ensuring that the mechanical properties meet the requirements, the hard segment cannot form crystals as much as possible or control the formation of crystals to the greatest extent. Ordinary sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com