On-line monitoring method for variation of through-flow gap of steam turbine

A steam turbine and clearance technology, which is used in mechanical clearance measurement, engine testing, and machine/structural component testing. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

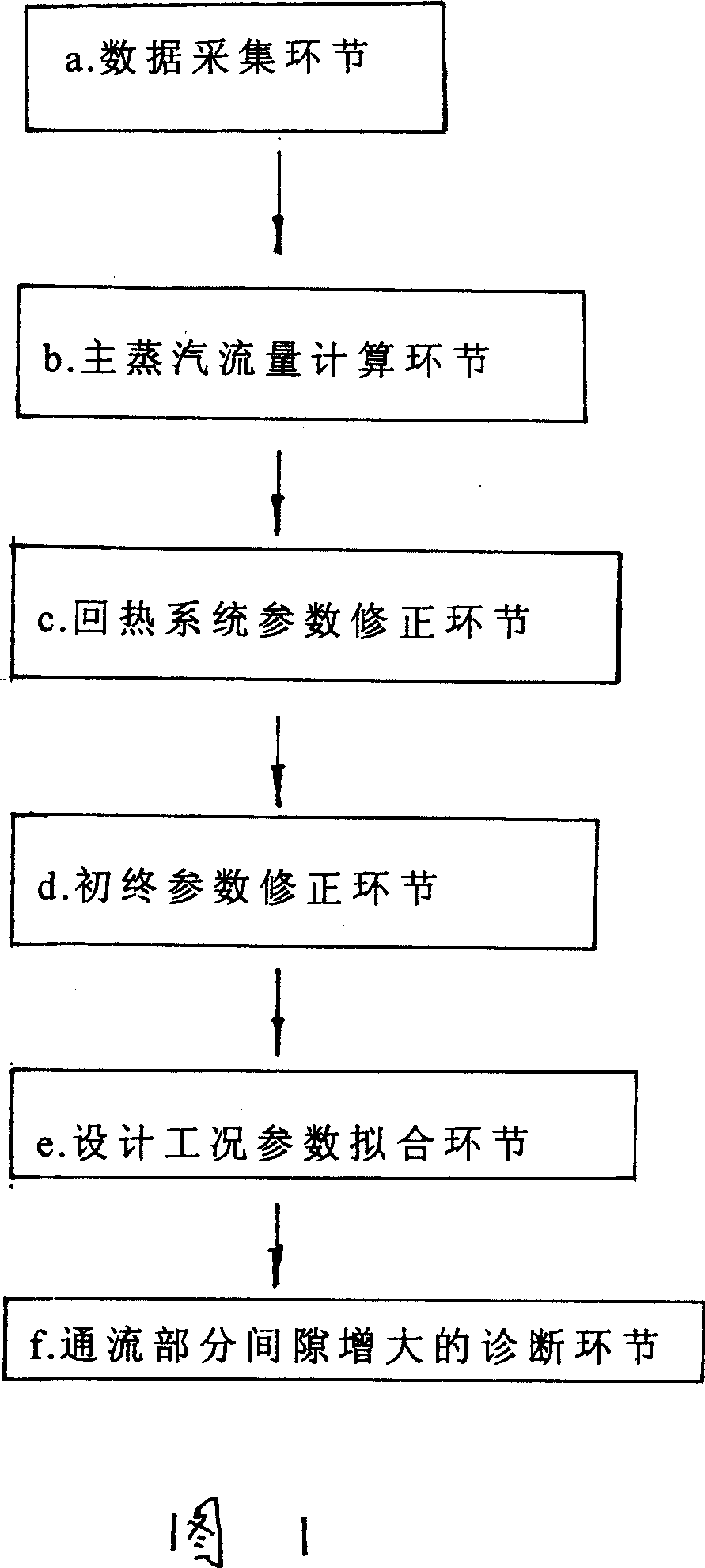

[0031] The specific implementation steps and calculation methods of the present invention will be further described below in conjunction with the accompanying drawings. It can be seen from Fig. 1 that the on-line monitoring method for the flow gap change of the steam turbine provided by the present invention mainly consists of the following links.

[0032] a. Data collection link: This link mainly calculates the pressure ratio before and after each stage group of the steam turbine, the relative internal efficiency of the stage group and the heat consumption rate of the steam turbine based on the data from the data acquisition system.

[0033] The present invention needs to monitor the parameter list

[0034] Generator end power (KW)

Water pressure at the outlet of feed water pump A (MPa)

Generator power factor (%)

Water temperature at outlet of feed water pump A (℃)

Main condensate flow (t / h)

Inlet steam pressure of small steam turbine B (MPa)

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com