LED (light emitting diode) service life test system and test method thereof

A technology for life testing and subsystems, applied in the LED fixed part, the structure of the hot and cold dual-zone temperature box, and the field of refrigerators, can solve the problems of increasing the test uncertainty, increasing the aging cost, and failing to achieve the test purpose. Improve reliability and continuity, improve test efficiency, facilitate the effect of failure causes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

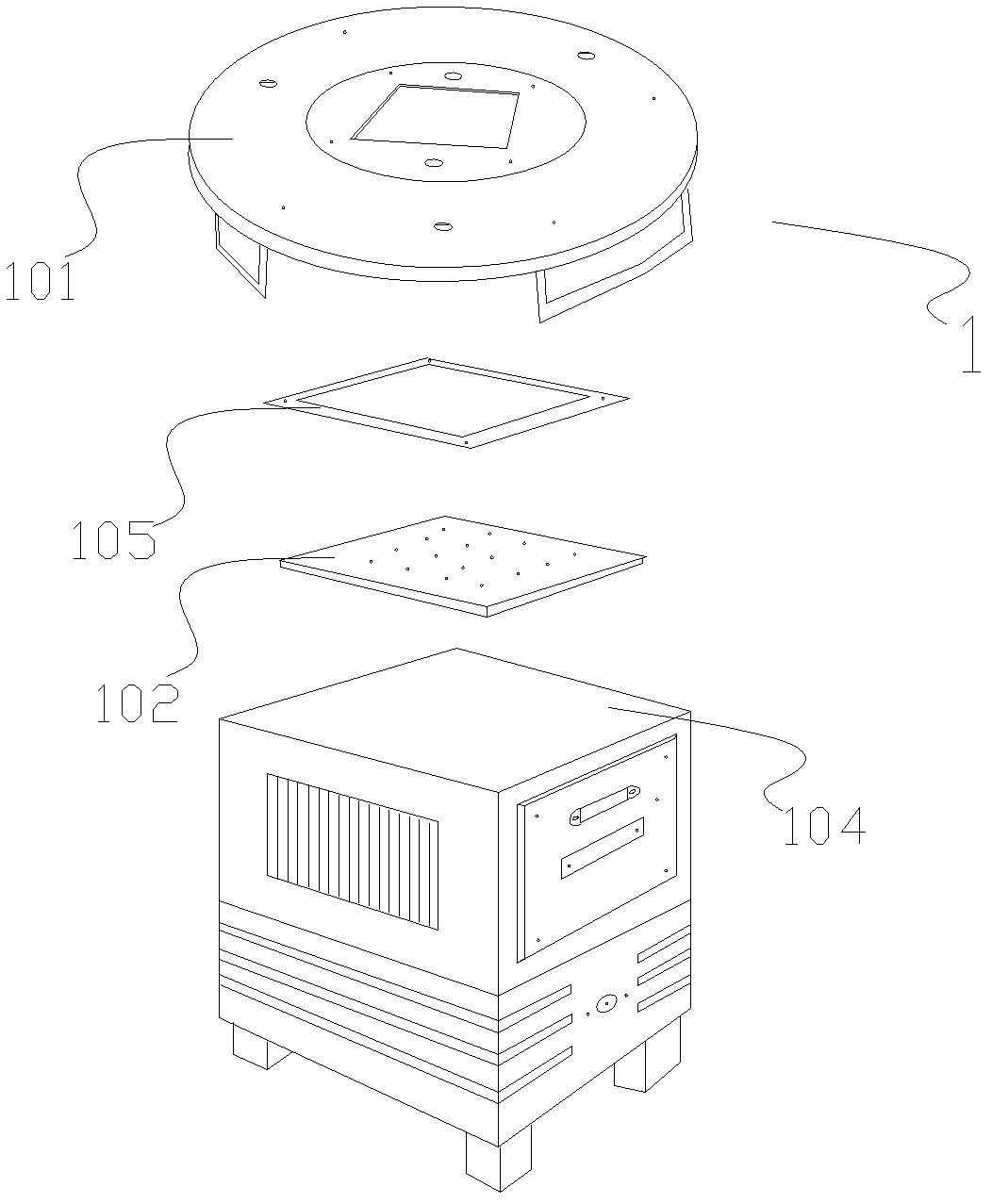

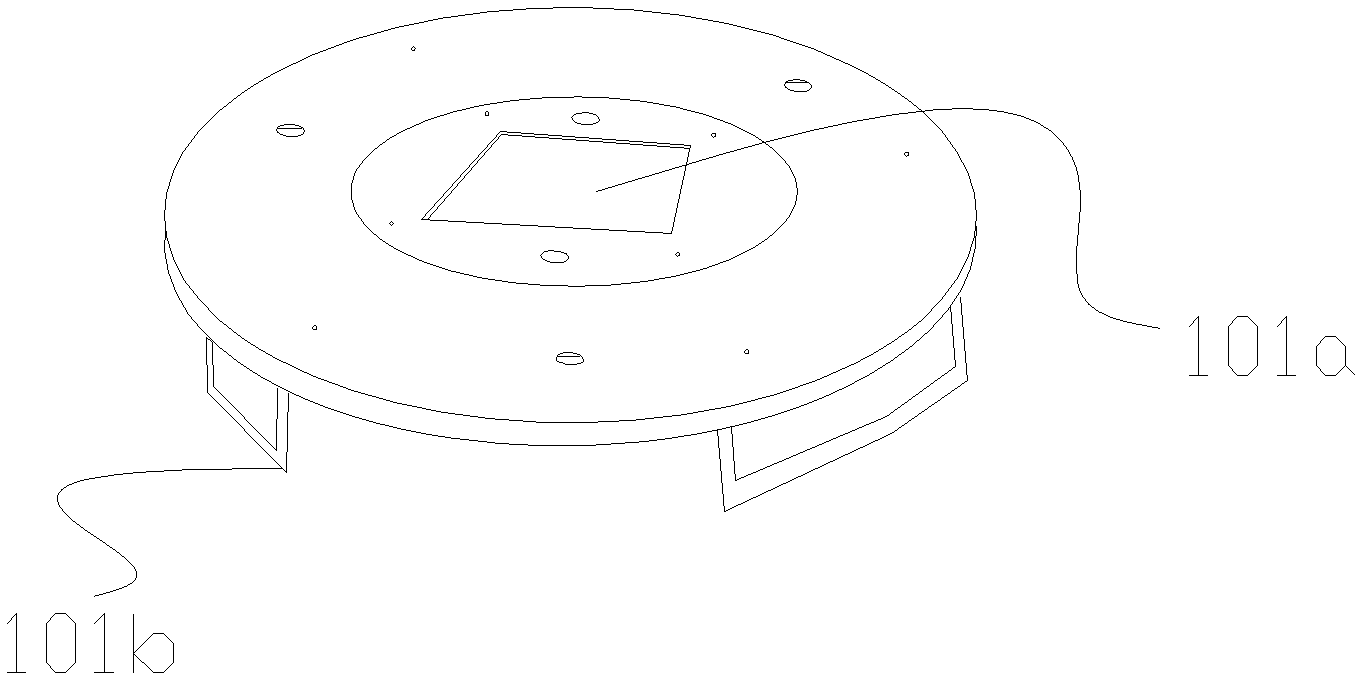

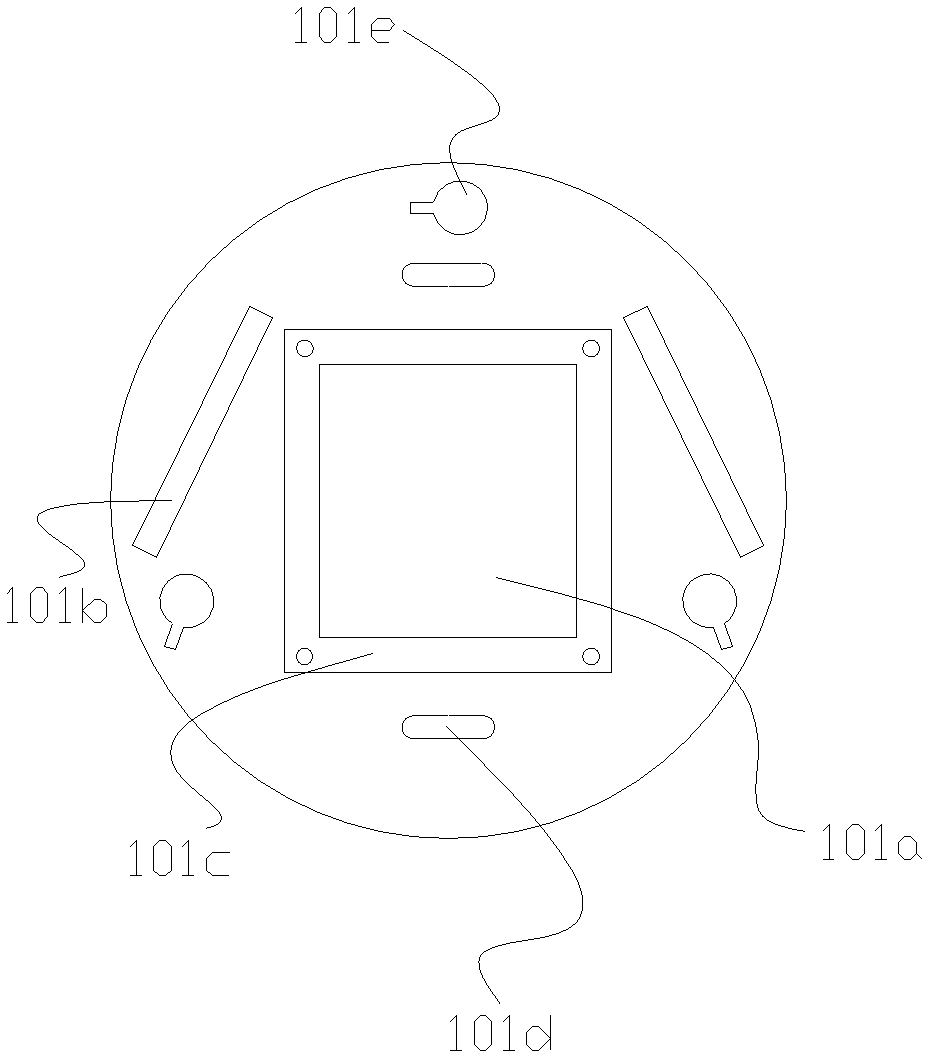

[0042] The LED life test system of the present invention includes an aging subsystem that uses a cold and hot dual-zone temperature box for aging and a measurement subsystem that uses an integrating sphere for photochromic and electrical measurements, and also includes such as figure 1 The cooler 1 shown and as Figure 4 The shown aluminum substrate 3 for welding multiple LEDs to be tested, such as Figures 1 to 4 As shown, the refrigerator 1 includes a mounting plate 101, an electric cooling plate 102 and a radiator 104, the electric cooling plate 102 and the mounting plate 101 are fixedly installed on the radiator 104, and the middle part of the mounting plate 101 has an opening 101a, the electric cooling plate 102 is embedded in the opening 101a (in this embodiment, the electric cooling plate 102 and the opening 101a can have a matching outline, so that the former is just embedded in the latter), and the radiator 104 is located on the side facing the bottom surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com