Earth pressure balance shield mud cake prevention system based on synchronous jet flow

A mud cake and high pressure technology, which is applied in the field of earth pressure balance shield mud cake prevention system, can solve the problems of increasing the main drive seal damage and opening the warehouse under pressure, cannot completely avoid the formation of mud cake, and does not consider mud cake flushing, etc., to achieve Avoid the reduction and damage of the main bearing seal life, avoid the risk of abnormal equipment damage, advanced and superior advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

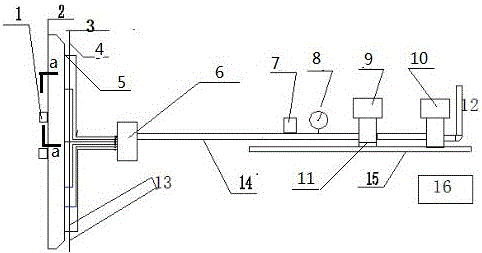

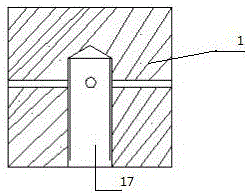

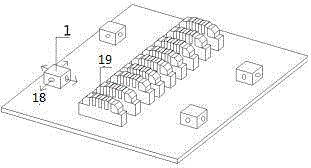

[0035]The technical solution of the present invention is: based on the principle of high-pressure water jet, that is, using high-pressure water generating device and using water as the working medium, after obtaining huge energy, it can be pre-installed in the soil bin partition, knife The specific nozzles and nozzles on the panel panel produce high-speed jet water jets to wash and cut the soil at different positions on the panel of the cutterhead, the back of the cutterhead and the soil bin to remove the generated mud cake or avoid the consolidation of the slag The mud cake is formed into blocks, so as to achieve the goal of synchronous mud cake prevention and shield tunneling. The use of this system also helps to improve the effect of muck improvement.

[0036] The mud cake prevention and control system of the present invention comprises: panel fixed nozzle, cutter head, shield body, earth bin partition, flushing gun, flushing point and pipeline connection, high-pressure pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com