Battery lamination stacking machine of lithium-ion power battery

A power battery and lithium ion technology, applied in the field of machines producing lithium ion power battery cells, can solve the problems of resource waste, environmental pollution, supply shortage, etc., and achieve the effect of reducing the required space, reducing costs, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

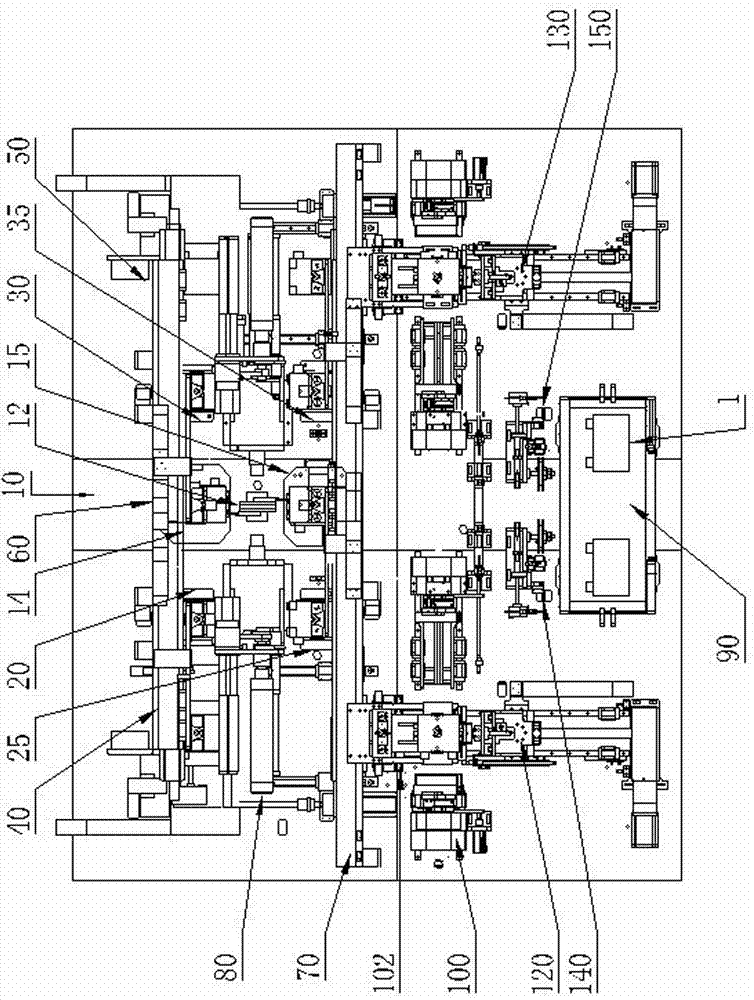

[0039] The cell stacking machine of lithium ion power battery of the present invention, such as figure 1 As shown, it discloses the specific structure of the preferred embodiment of the present invention, including a pole piece magazine mechanism 10, a positive electrode secondary positioning mechanism 20, a negative electrode secondary positioning mechanism 30, A stacking table mechanism 40, and B stacking Table mechanism 50, positive electrode picking arm 60, negative electrode picking arm 70, diaphragm unwinding mechanism 80, cell conveyor belt 90, winding mechanism A 100, winding mechanism B 110, cell transfer mechanism A 120, electric Core transfer mechanism B 130, glue application mechanism A 140, glue application mechanism B 150.

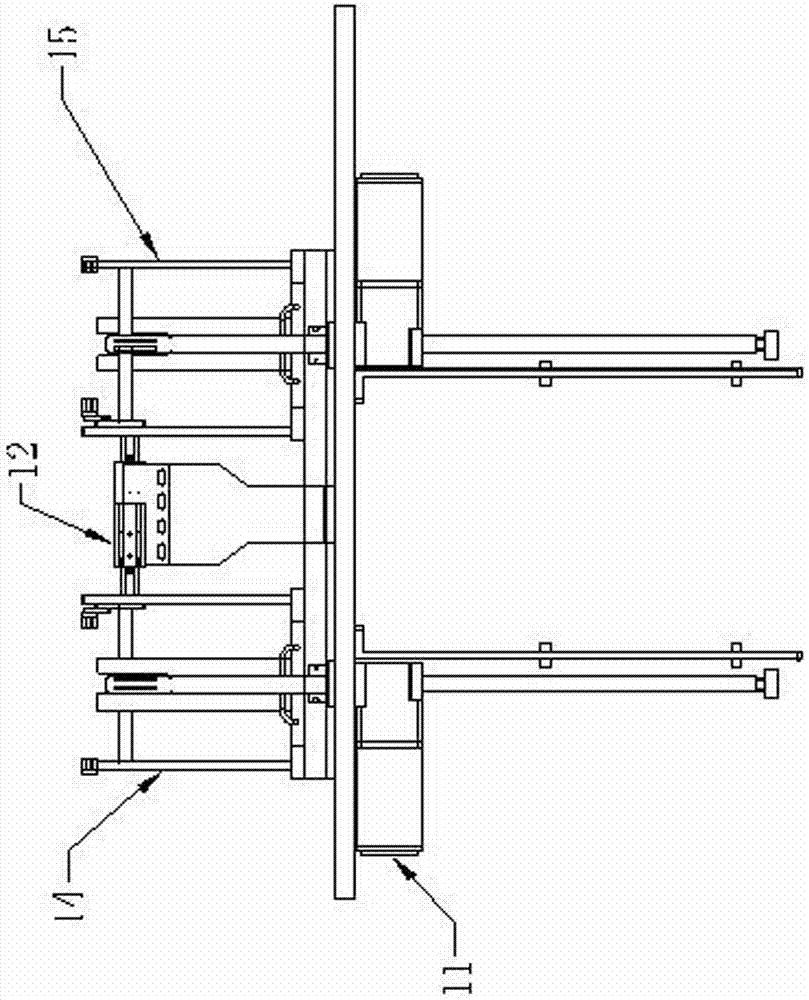

[0040] The pole piece material box mechanism 10 is used to provide different types of pole pieces to be laminated, and it includes a pole piece feeding auxiliary device and a pole piece feeding lifting mechanism 11. The pole piece feeding auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com