Electric car chassis battery charging and replacing station and battery replacing method using same

A technology for electric vehicles and charging and swapping stations. It is applied in the direction of electric vehicles, charging stations, and electric power devices. It can solve the problems of low space utilization, long transmission line distance, and large site occupation, and achieve high space utilization. The effect of quick change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

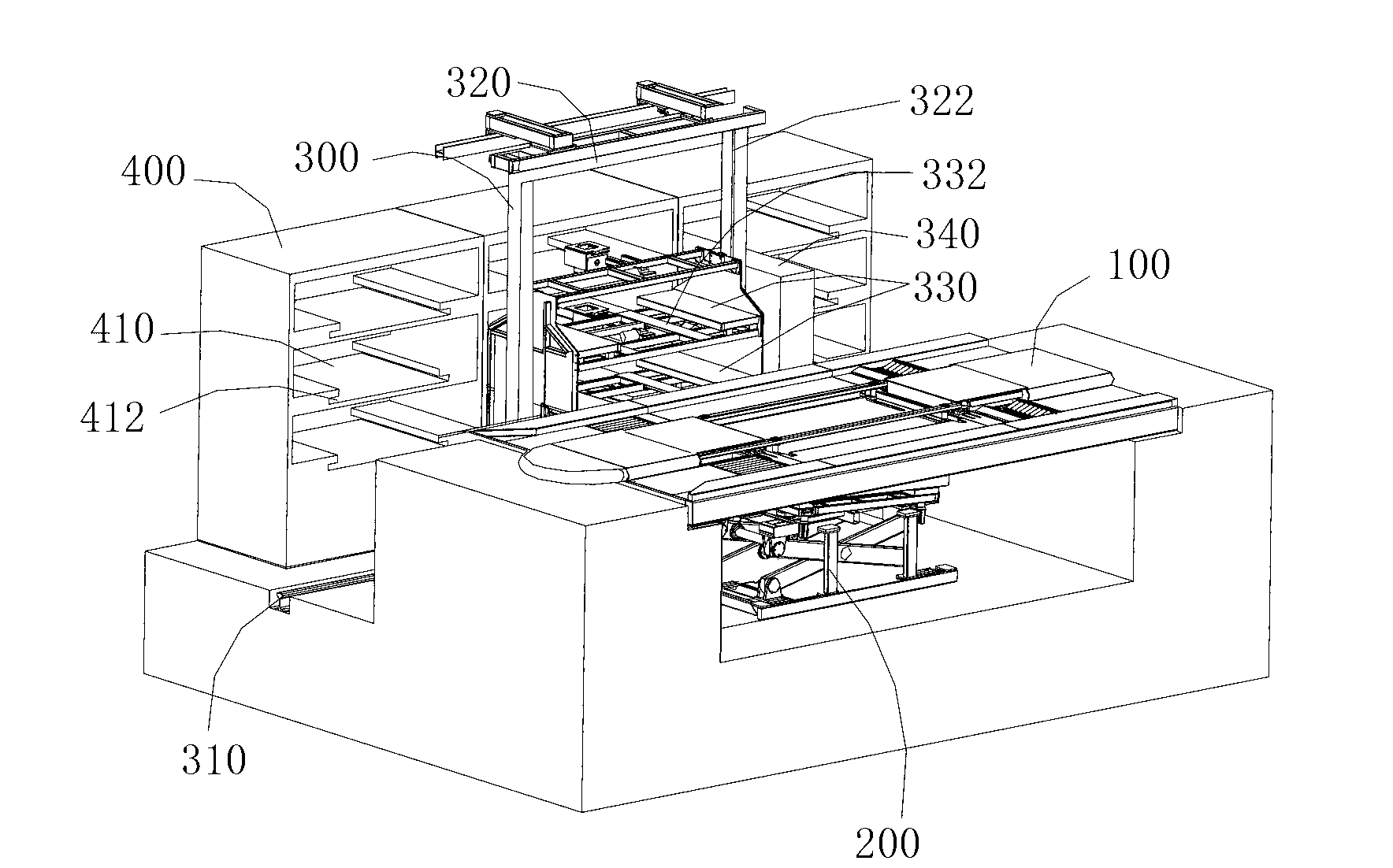

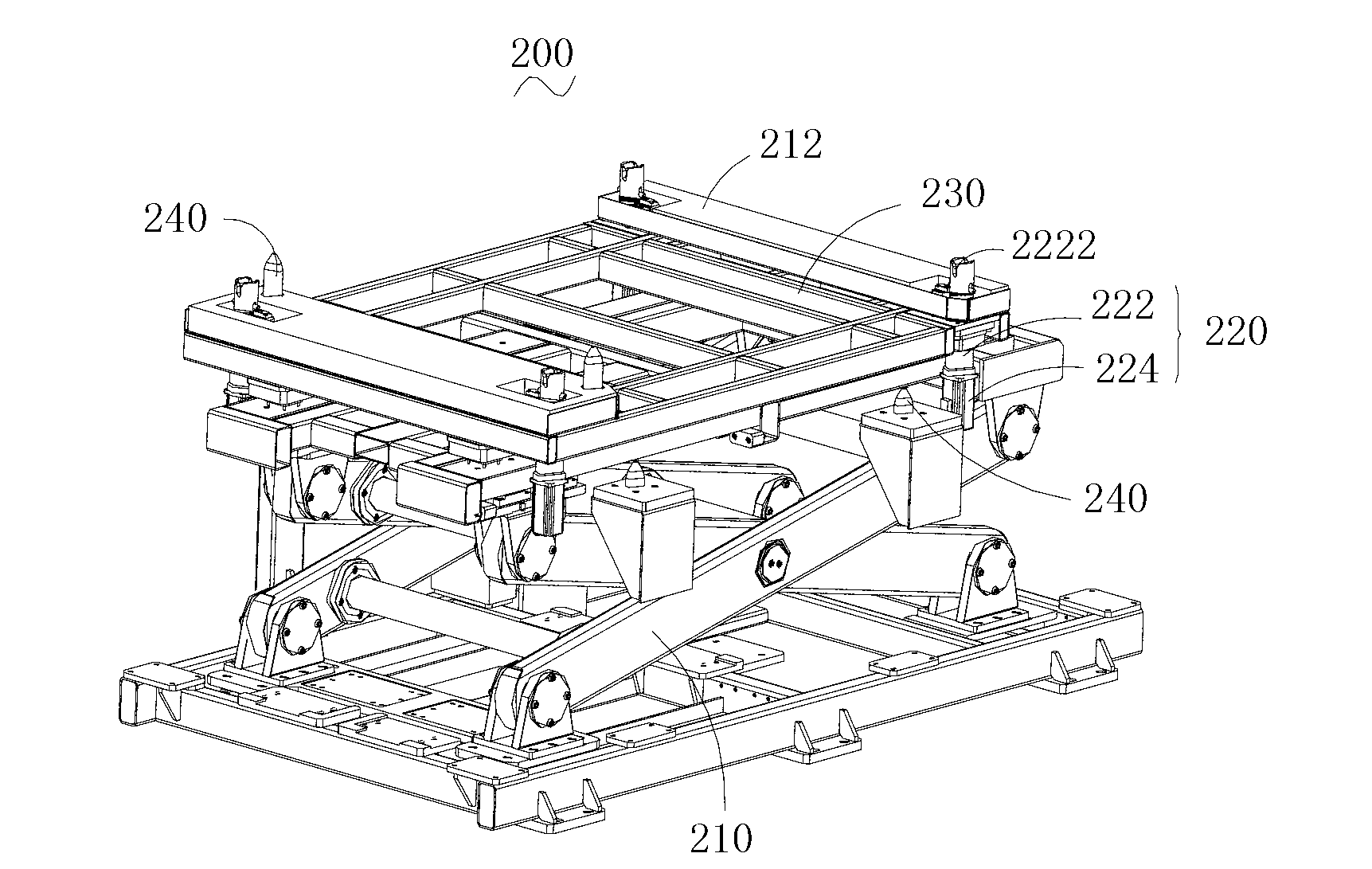

[0035] Please refer to Figure 1 to Figure 7 This embodiment discloses an electric vehicle chassis charging and swapping station, including a vehicle centering device 100 , a battery lifting and replacing device 200 , a track-type roadway stacker 300 , a battery storage rack 400 , a battery handling device 500 and a battery charging device 600 . Using the movement of the track-type roadway stacker 300 to make the battery handling device 500 walk among the battery lifting and replacing device 200, the track-type roadway stacker 300 and the battery storage rack 400, so that the transportation of the battery can be completed without a conveyor line. Therefore, the electric vehicle chassis charging and replacing station has a higher space utilization rate.

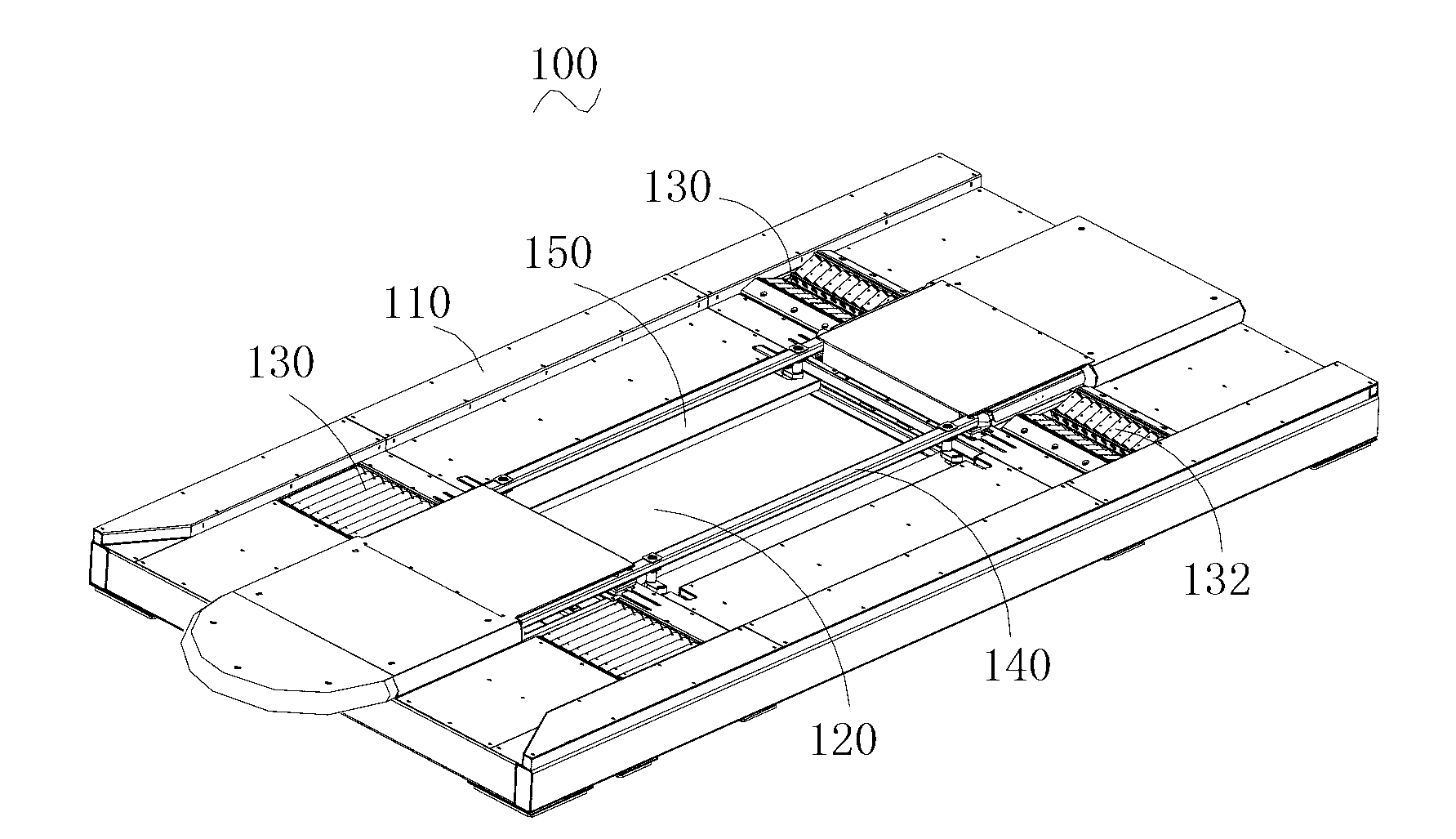

[0036] Please refer to figure 1 with figure 2 , the automobile centering device 100 is used for parking the vehicle and the lateral and longitudinal positioning of the vehicle. It is provided with a main frame 110, a batter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com