Flat steel automatic collecting and stacking machine

An automatic collection and stacker technology, which is applied to the stacking, transportation and packaging of objects, can solve the problems of unsuitability for large-scale production, low degree of automation, and large labor consumption, etc., to achieve a feasible principle, compact equipment layout, High interchangeability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

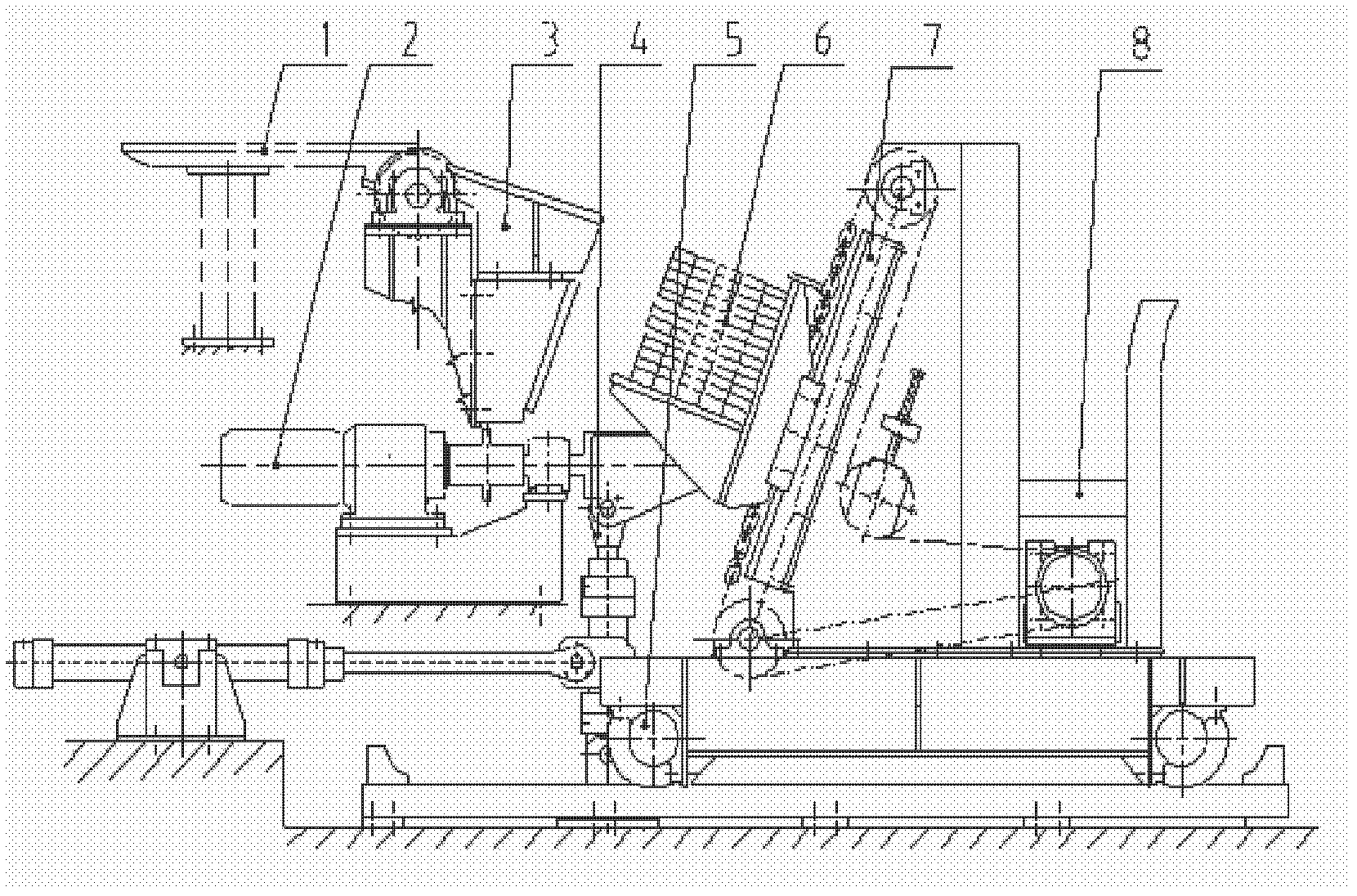

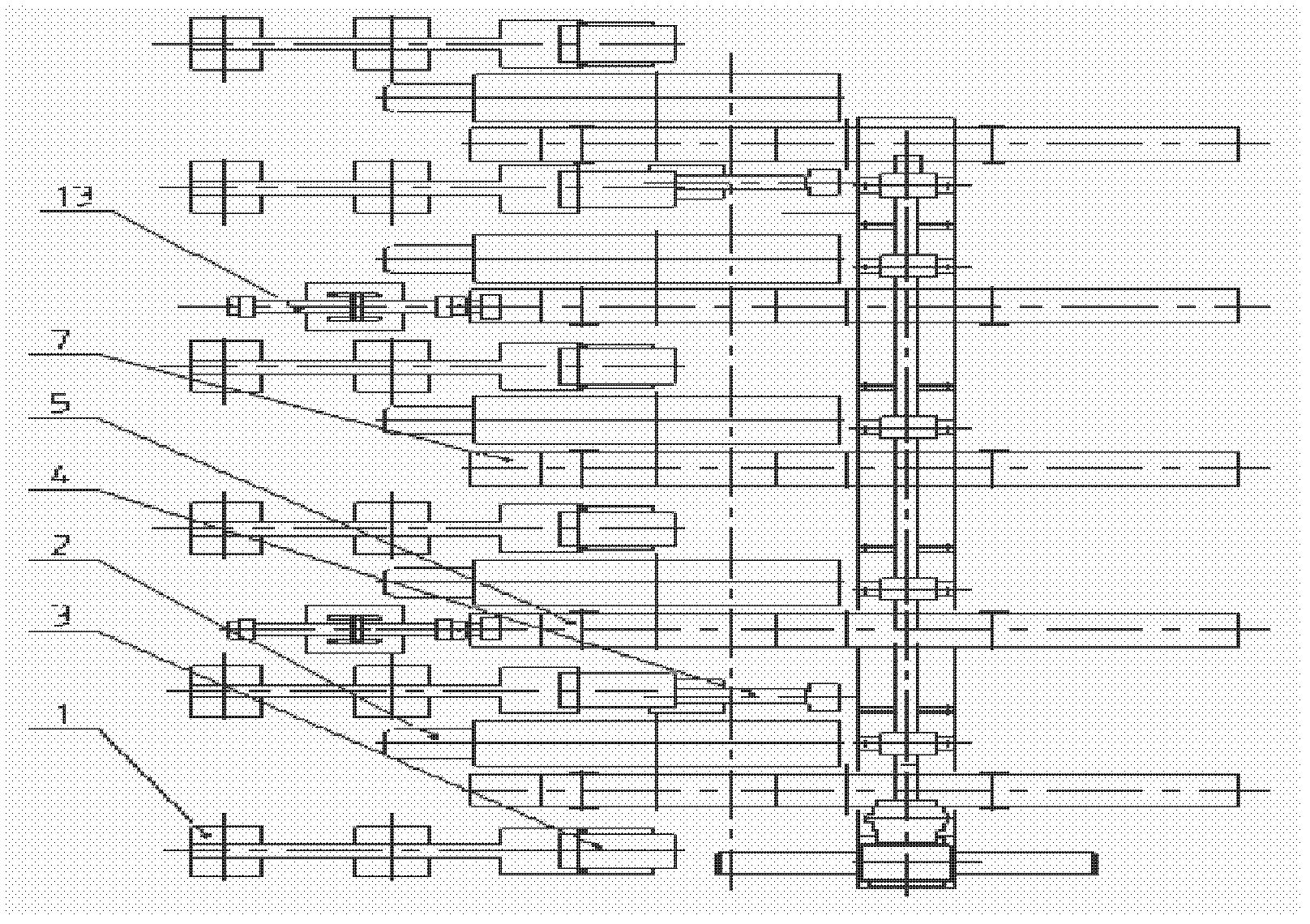

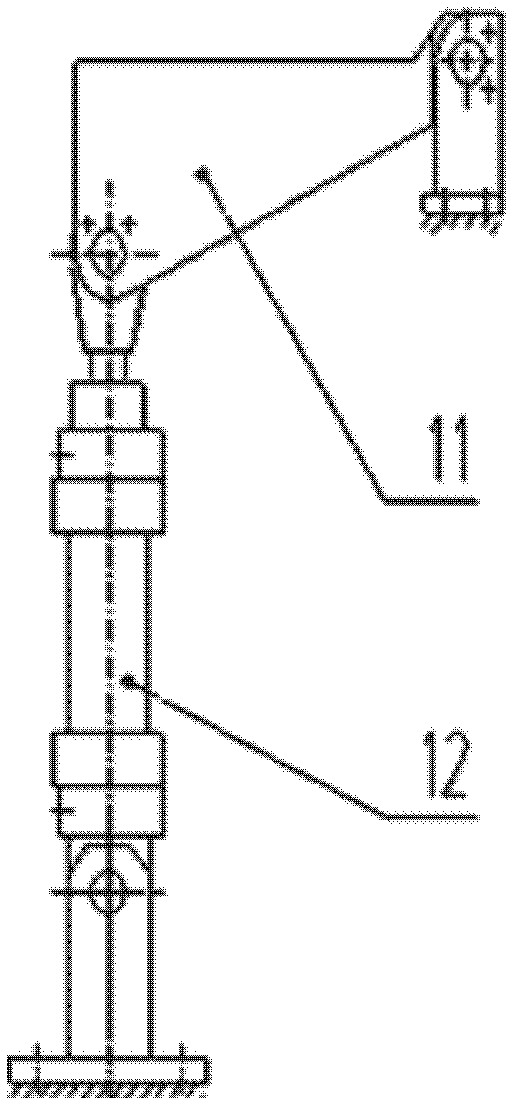

[0014] Embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing: figure 1 , figure 2 A flat steel automatic collecting and stacking machine shown is composed of a chain conveying platform 1 and a material receiving platform 3 connected with the chain conveying platform 1, located between the chain conveying platform 1 and the material receiving platform 3 The conveying roller table 2 below is composed of multiple sets of staggered turning mechanisms 4, traversing mechanisms 5, stacking flat steel 6, lifting mechanism 7, and material collecting frame 8; the material receiving platform 3 is composed of material receiving guide plates 9 and The alignment baffle 10 is composed of the material receiving guide 9 and the alignment baffle 10 fixed by bolts, and the alignment baffle 10 is fixed on the column of the chain conveying platform 1 by bolts; as image 3 Shown: turning mechanism 4 is mainly made up of turning supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com