Rapid automatic loading and stacking machine for container

A container and palletizer technology, which is applied in the field of fast and automatic container loading and palletizing machines, can solve the problems of complex structure of palletizing machines and unsatisfactory palletizing speed, and achieve shortening of packing time, improvement of palletizing speed, and mechanism simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

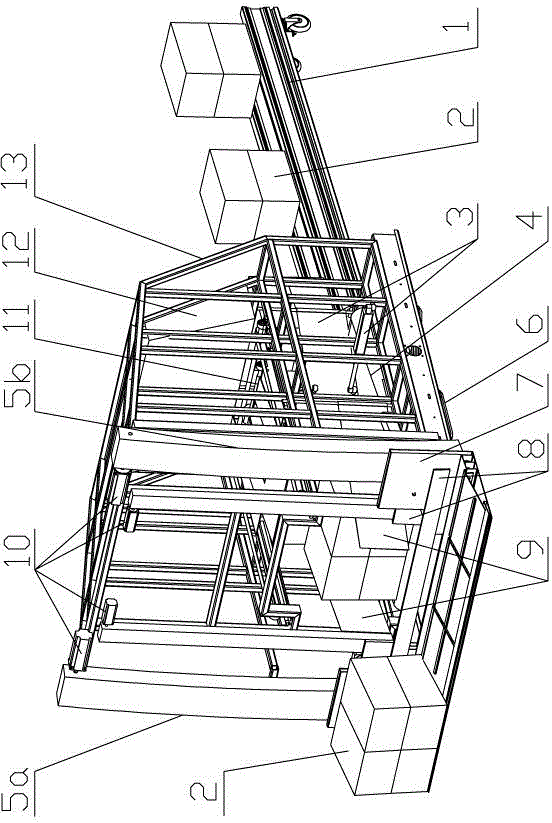

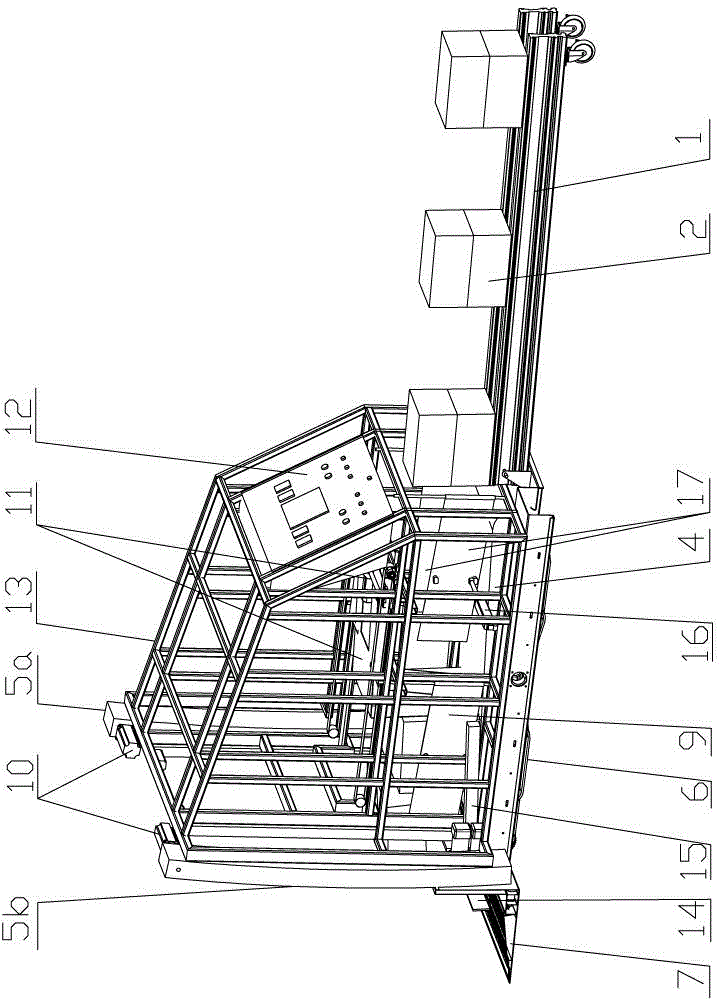

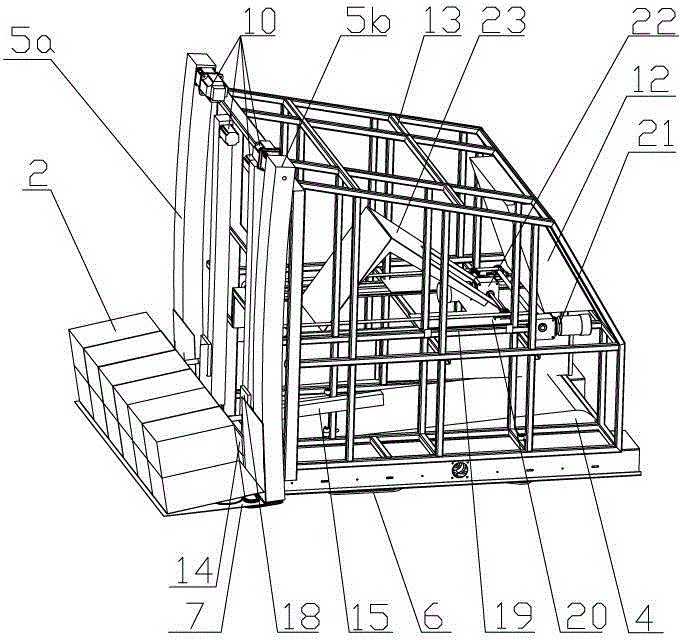

[0019] see Figure 1-3 , the present invention has self-propelled type frame frame 13, and frame 13 bottom both sides are provided with crawler type running mechanism 6, and conveyor belt 4 is installed on the bottom of frame frame 13 (for conventional technology, comprises motor, transmission Mechanism, transmission belt, wherein the transmission belt selects ball transmission belt to facilitate the packing box to move left and right and put it in a row), especially: the front end of the frame-shaped frame 13 is equipped with left and right lifting guide rails 5a, 5b, and the two lifting guide rails are equipped with Elevating pallet 7, and push box mechanism 8 (in the present embodiment, be push box mechanism 3, be provided with left and right guide rails in addition, also can be made into one with lifting guide rail certainly) with lifting pallet 7 lifting movement together with lifting pallet 7, equipped with The lifting drive mechanism 10 of the lifting pallet 7 and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com