Stereoscopic warehouse goods checking method and system

A three-dimensional warehouse and cargo technology, applied in the field of logistics, can solve the problems of consuming manpower and material resources, affecting work efficiency, and being unable to achieve fast inventory, and achieve the effect of fast speed and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

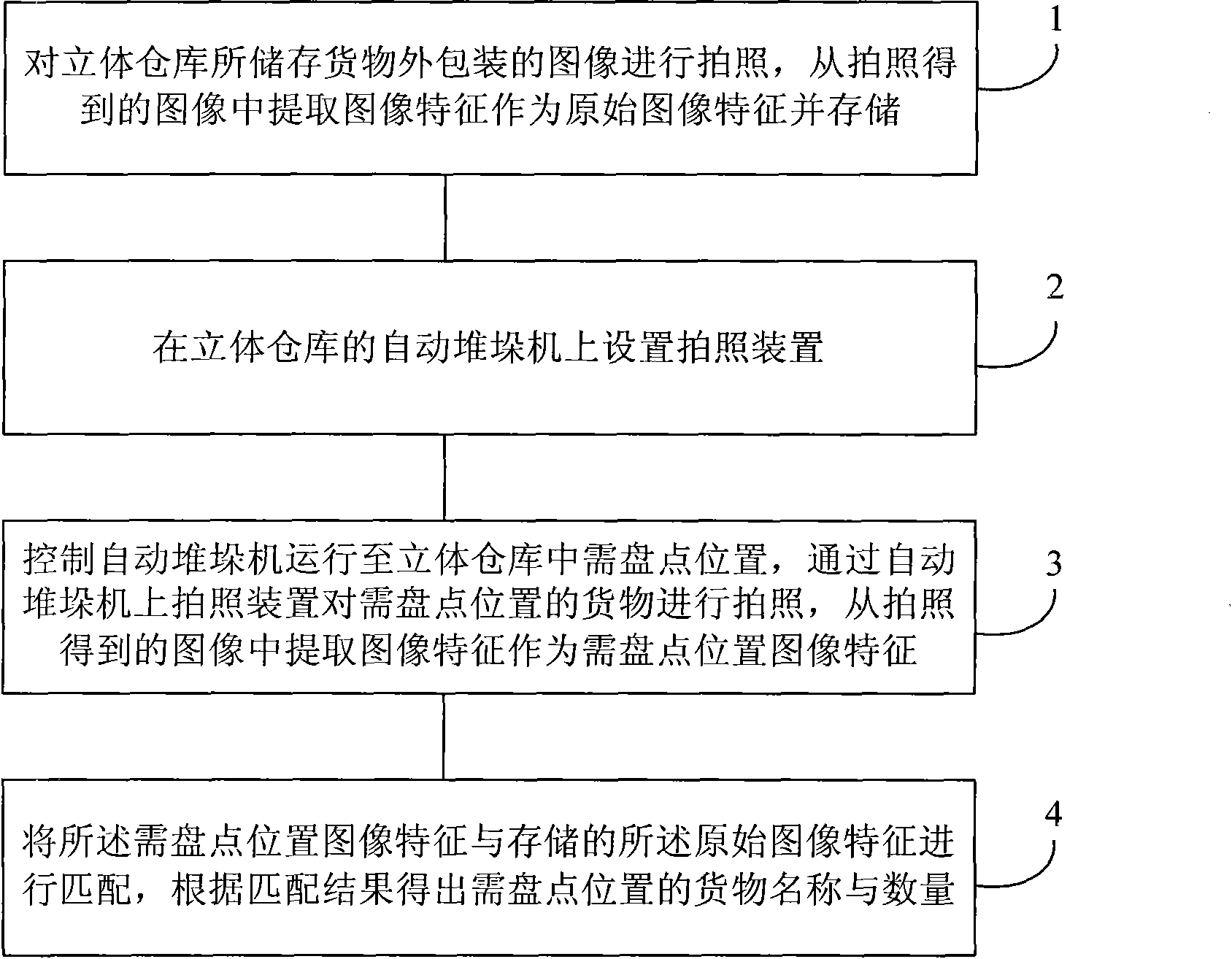

[0042] This embodiment provides a method for inventorying goods in a three-dimensional warehouse, which is used for inventorying the goods in the three-dimensional warehouse, such as figure 1 As shown, the method includes the following steps:

[0043] Step 1, taking pictures of the images of the outer packaging of the goods stored in the three-dimensional warehouse, extracting image features from the images obtained by taking pictures as original image features and storing them; the extracted original image features can be stored in the database of the processing device;

[0044] Step 1, install a camera device on the automatic stacker in the three-dimensional warehouse, and the camera device can use a digital camera or a video camera;

[0045] Step 3, control the automatic stacker to run to the position to be counted in the three-dimensional warehouse, take pictures of the goods at the position to be counted through the camera device on the automatic stacker, and extract the ...

Embodiment 2

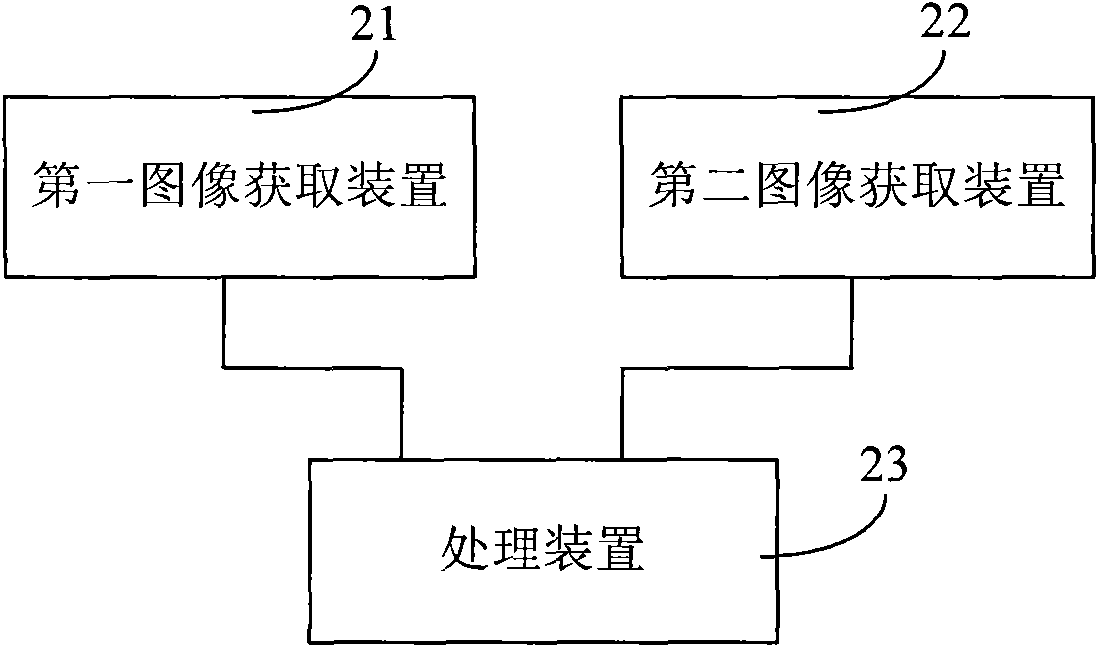

[0052] This embodiment provides a three-dimensional warehouse goods inventory method, which is used to realize the inventory of three-dimensional warehouse based on image recognition, such as figure 2 As shown, the system includes:

[0053] A first image acquisition device 21, a second image acquisition device 22 and a processing device 23;

[0054] The first image acquisition device 21 is used to take pictures of the images of the outer packaging of the goods stored in the three-dimensional warehouse, and transmit the images obtained by the pictures to the processing device;

[0055] The second image acquisition device 22 is used to be arranged on the automatic stacker of the three-dimensional warehouse. When the automatic stacker runs to the position to be counted in the three-dimensional warehouse, the goods at the position to be counted are photographed, and the images acquired by the photograph are transmitted. to said processing unit;

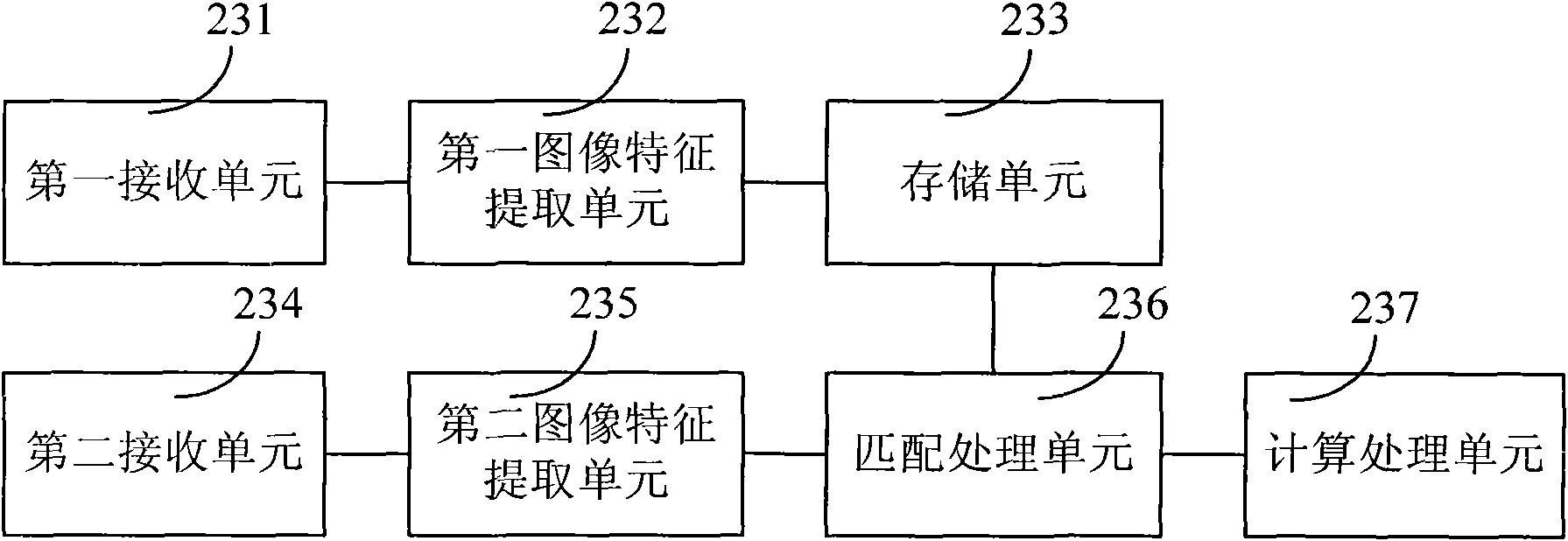

[0056] The processing device 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com