Stacking machine

A palletizer and deceleration motor technology, which is applied in the field of palletizers, can solve the problems of palletizer transfer mechanism wear, block breakage, etc., and achieve the effect of not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

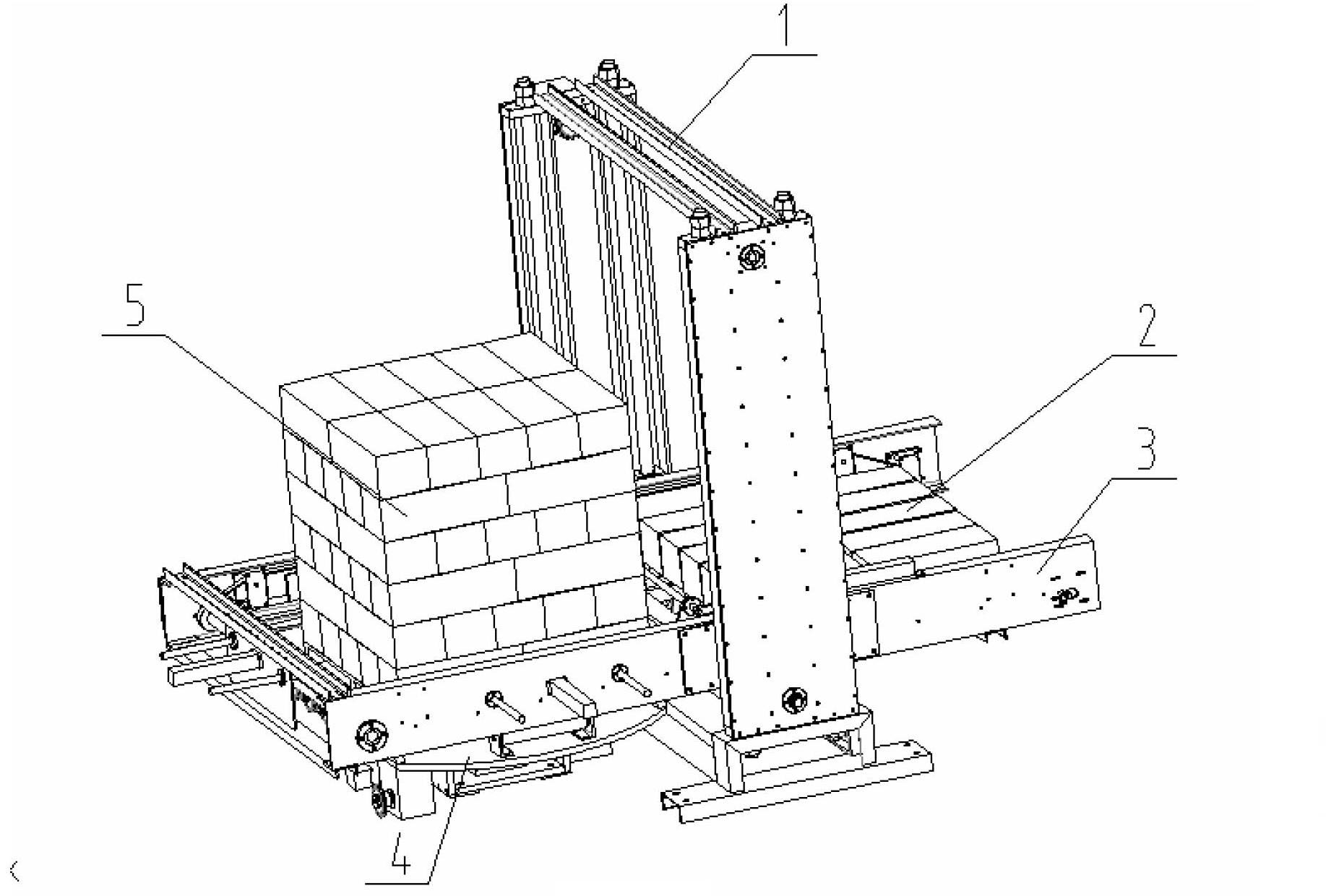

[0040] refer to Figure 1 to Figure 15 , a palletizer, including a lifting traction device 1, a lifting device 3, a stacking device 2 and a stacking rotary table 4; the lifting traction device 1 is connected to the lifting device 3 by transmission, and the stacking device 2 Move within the lifting device 3; one side of the stack pushing device 2 is provided with the stack supporting rotary table 4;

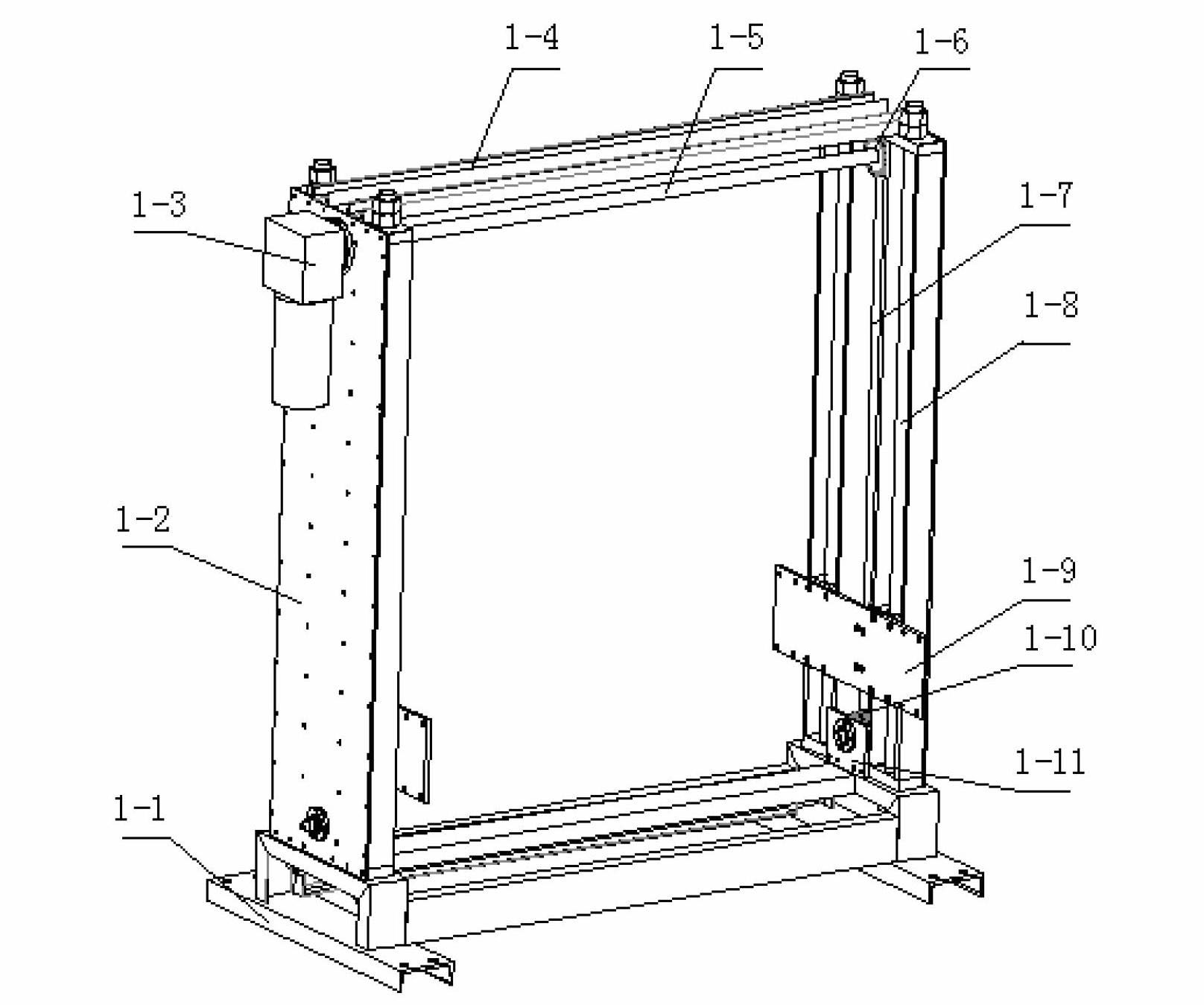

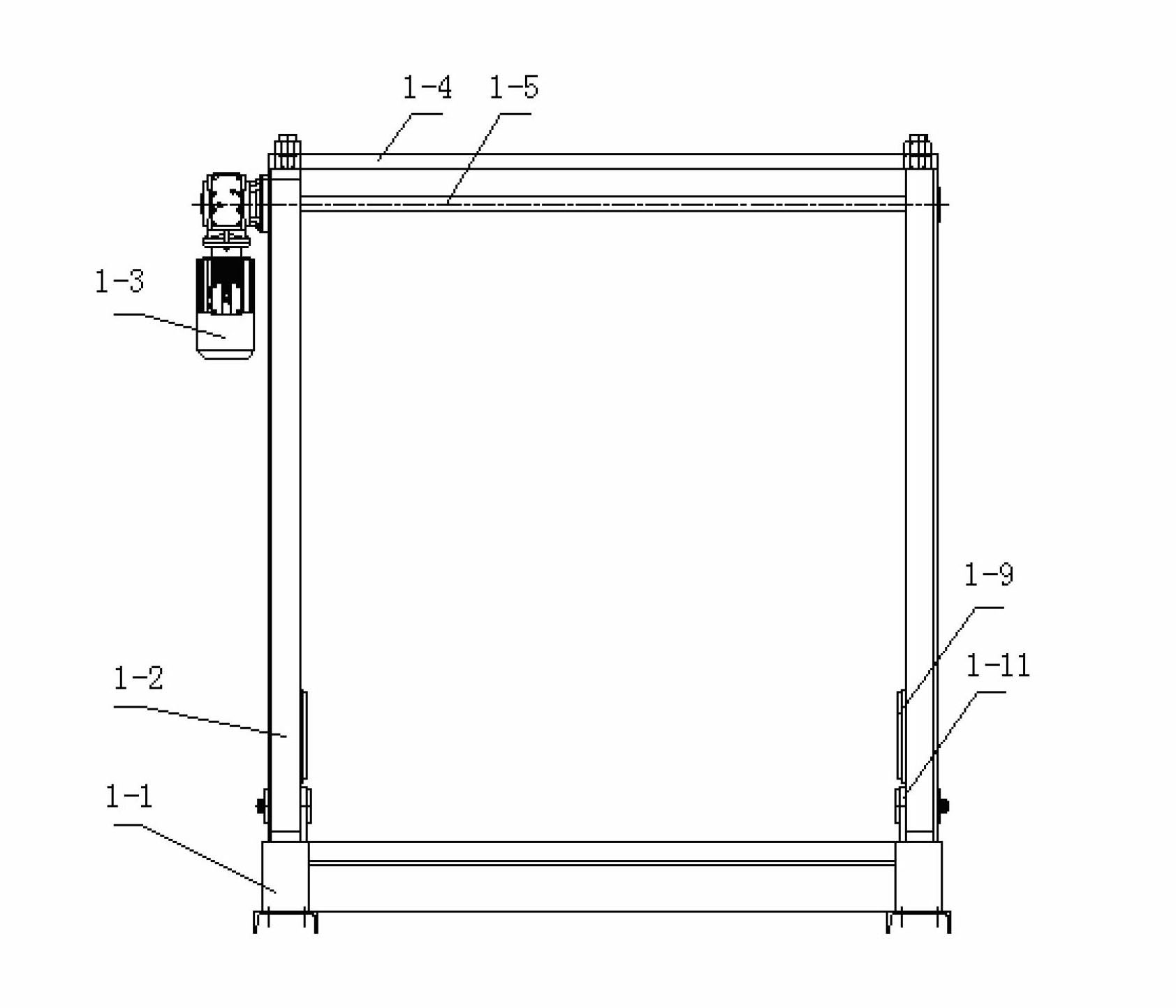

[0041]The lifting traction device 1 includes a lifting traction frame 1-1, a column 1-2, a geared motor 1-3, a beam 1-4, a drive shaft 1-5, a driving sprocket 1-6, a chain 1-7, a guide Column 1-8, guide sleeve 1-12, lifting device installation connecting plate 1-9 and tensioning sprocket 1-10, one end of the column 1-2 is respectively connected to both sides of the lifting traction frame 1-1; The other end is connected with the beam 1-4 to form a gantry structure; the geared motor 1-3 is installed on the upper side of the column 1-2 on one side, and one end of the drive shaft 1-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com