Autonomic logistics tower system

A logistics tower, automatic technology, applied in the field of warehousing and logistics, can solve the problem of low utilization of shelf space, and achieve the effect of shortening the running time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

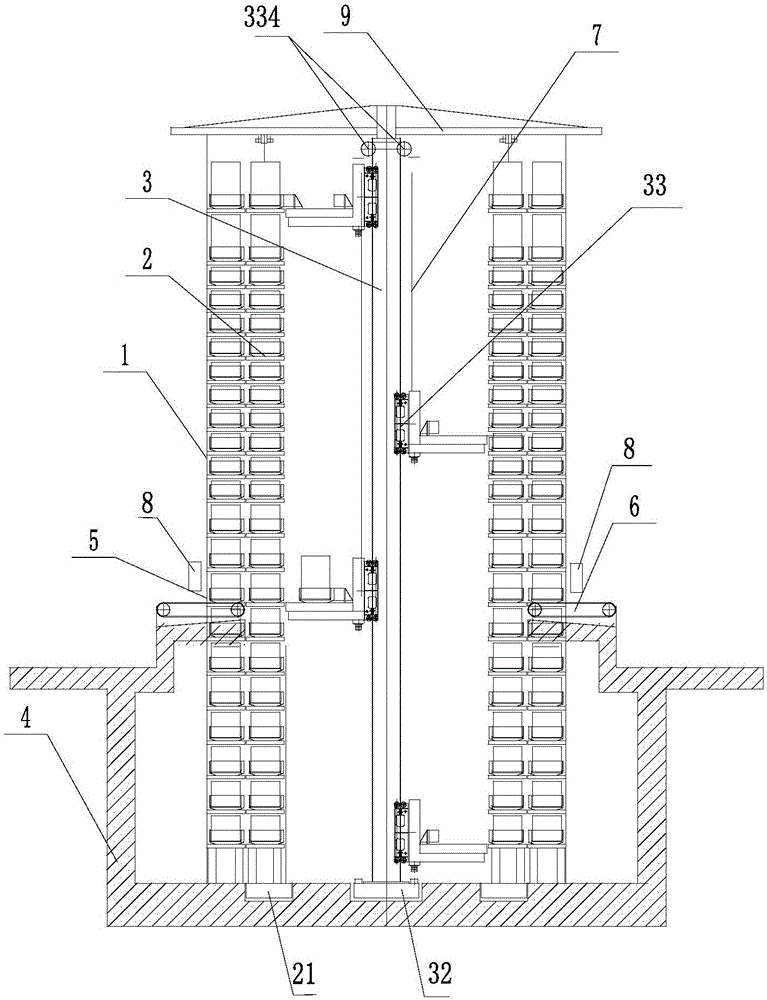

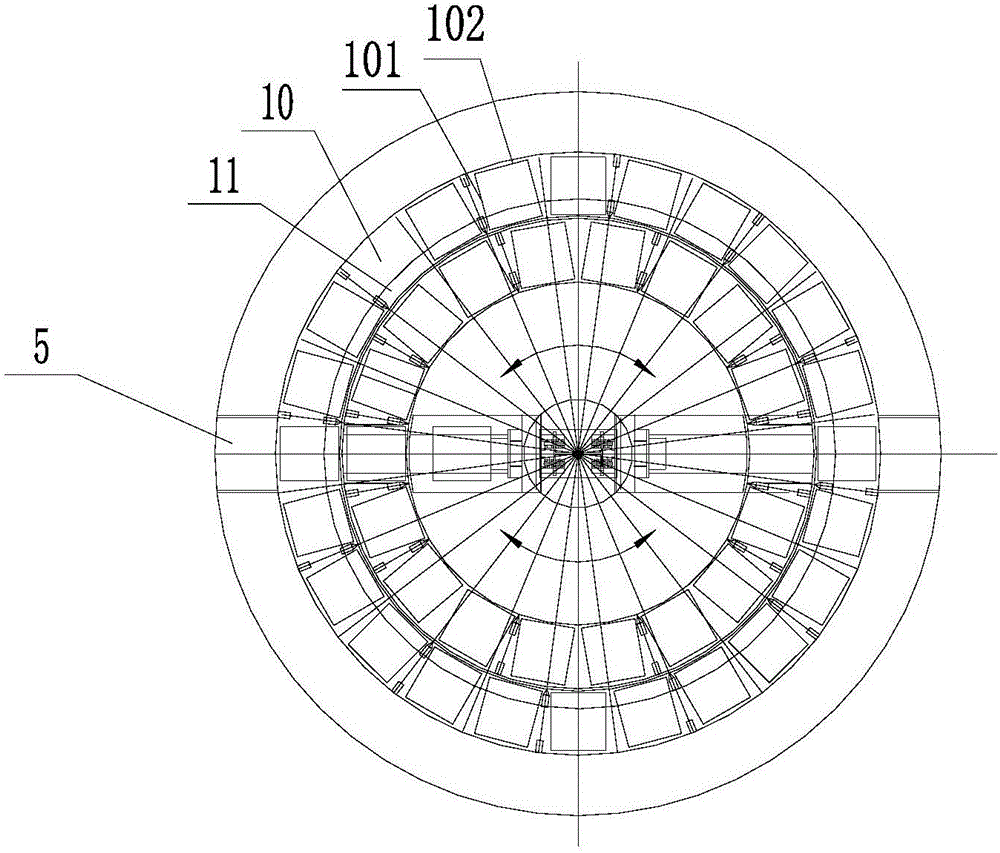

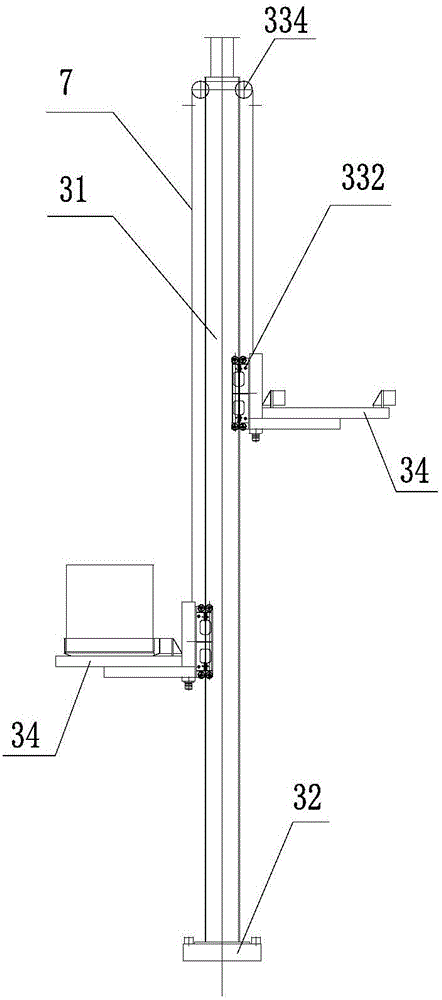

[0035] Embodiments of the present invention disclose an automatic logistics tower system, such as Figure 1 to Figure 10 As shown, including fixed shelf 1, rotating shelf 2, palletizer 3, bottom warehouse 4 and control system, the cross sections of fixed shelf 1 and rotating shelf 2 are circular, and fixed shelf 1 is provided with two relative There are 5 imports and exports of goods, and the rotating shelf 2 is located in the fixed shelf 1, and there is a gap between the fixed shelf 1 and the fixed shelf 1, which not only leaves a margin for the assembly of the fixed shelf 1 and the rotating shelf 2, but also ensures the rotation of the rotating shelf 2. Rotational movement. The rotating shelf 2 is provided with two rows of open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com