Full-automatic slitting and arranging device for pipes

A finishing device, fully automatic technology, applied in the direction of pipe shearing device, shearing device, positioning device, etc., can solve the problems of inability to split the pipe, and the plate cannot be automatically stacked and stored, so as to achieve tight push connection and avoid string Position card material, improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

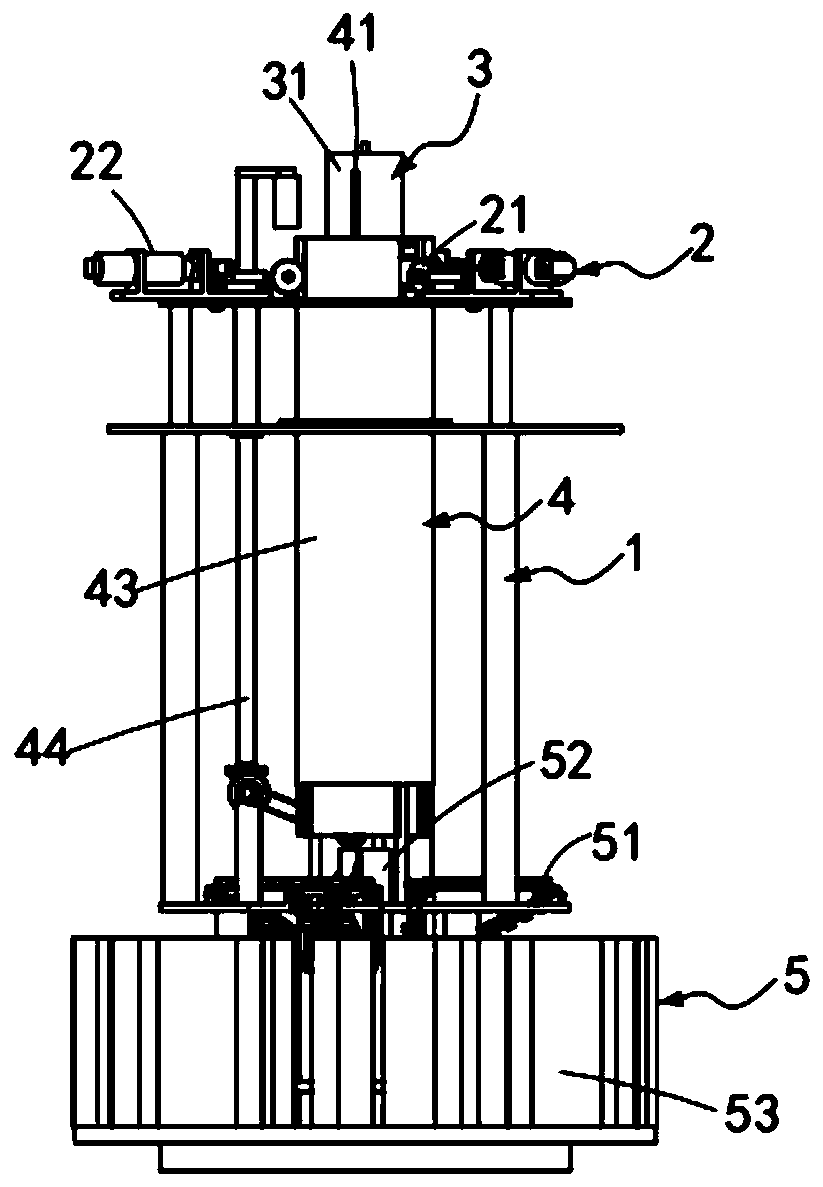

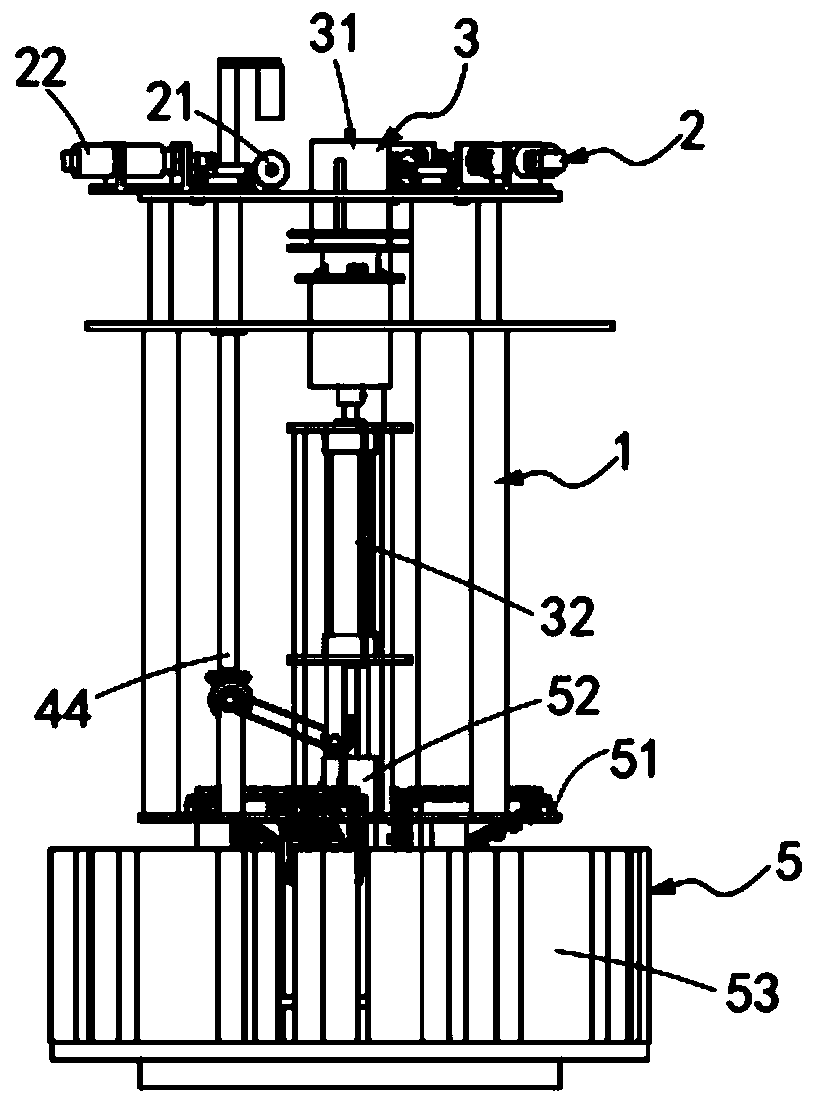

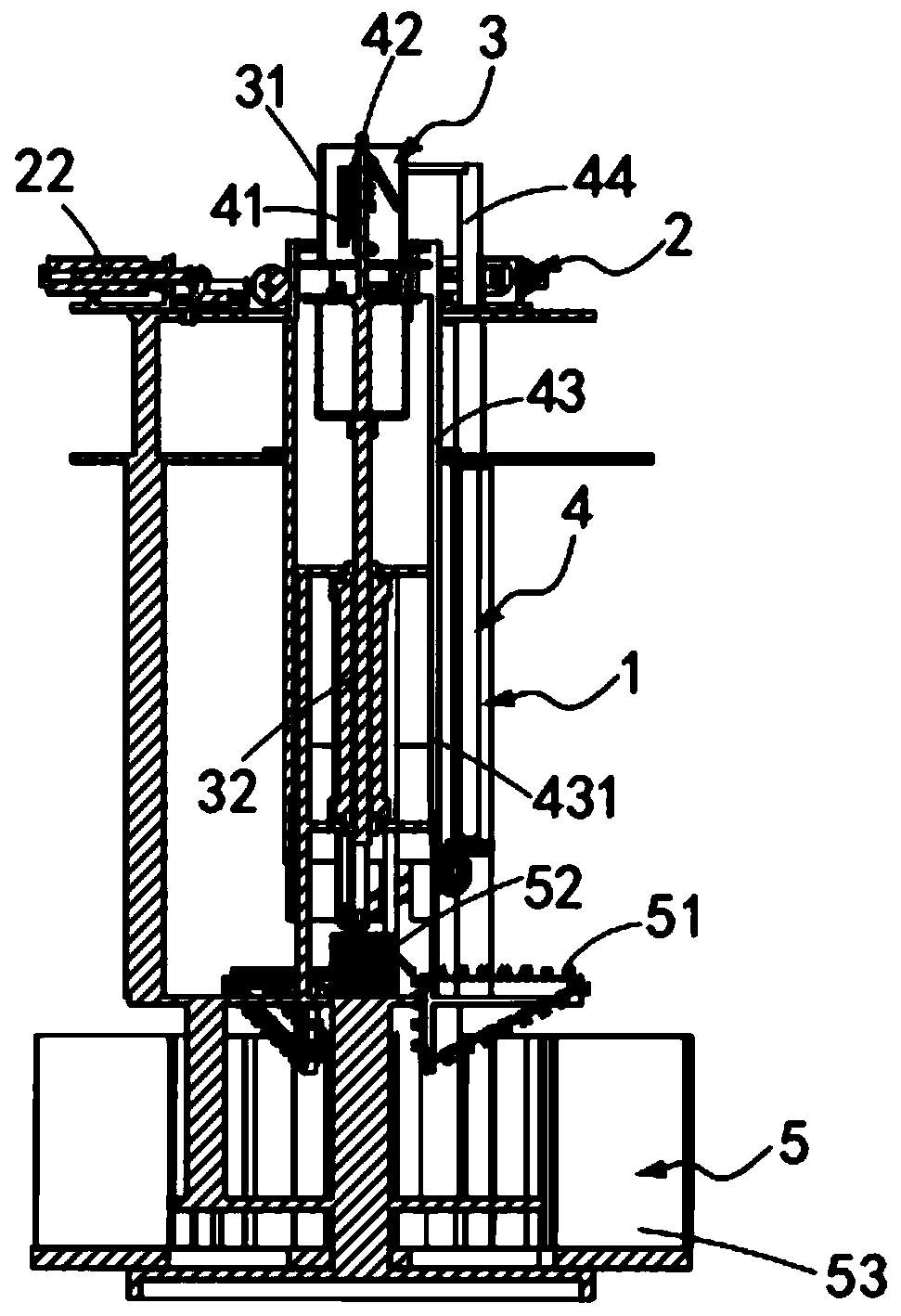

[0076] Such as Figure 1 to Figure 5 As shown, a pipe automatic cutting device, including:

[0077] bracket 1;

[0078] Cutting mechanism 2, described cutting mechanism 2 is installed on the top of described support 1, and it comprises several cutting knives 21 that are equidistantly arranged along the axial circumference of described support 1, and these cutting knives 21 all point to support 1 center line, and the slitting knife 21 is manipulated and telescopically set by the corresponding telescopic assembly 22;

[0079] The supporting mechanism 3, the supporting mechanism 3 is arranged on the axial direction of the support 1, which includes a supporting cylinder 31 carrying the pipe to be cut and driving the supporting cylinder 31 along the axial direction of the support 1 Carry out the double-headed cylinder 32 that moves up and down, this double-headed cylinder 32 is arranged on the whole below of described material holder 31, and it is vertically installed on the desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com