Stacking machine with two layers of objective tables

A technology for a carrier and a stacker, applied in the field of stackers, can solve problems such as low flexibility and inability to complete multiple material storage, and achieve the effects of improving single throughput, work efficiency and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

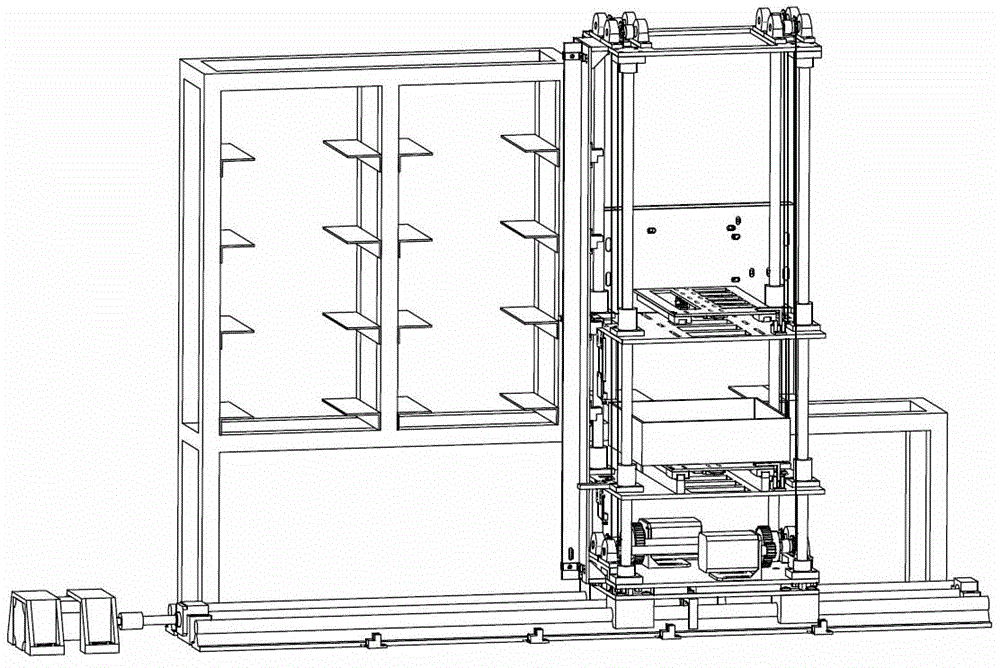

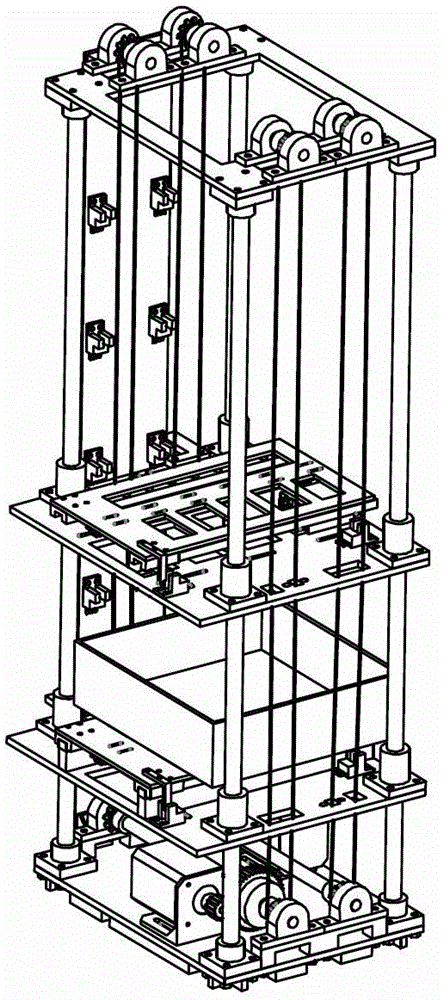

[0027] A stacker with a double-layer loading platform has three working modules: a horizontal movement module, a vertical movement module, and a loading platform working module, and each module works independently.

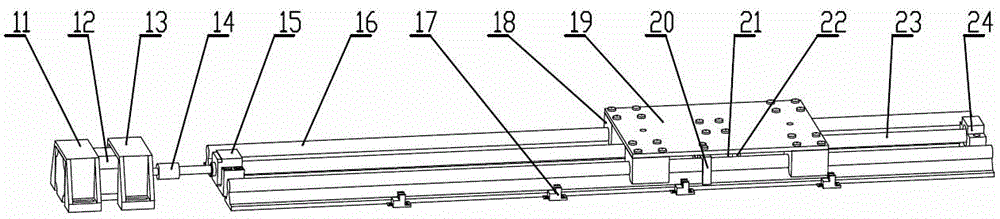

[0028] (1) Horizontal movement module

[0029] The horizontal movement module consists of such as figure 2 The components shown are composed: the horizontal mobile platform 19 is fixedly connected with the guide rail slider 18, and the four sliders are fixedly connected on the four corners of the horizontal mobile platform, and move along the axial direction of the guide rails respectively on the two guide rails 16, while the horizontal mobile platform 19 is fixedly connected with the ball screw nut 22 through the fixing seat 21, the output shaft of the motor 12 is connected with the ball screw 23 through the coupling 14, the motor 22 is fixed by the motor fixing brackets 11 and 13, and the ball screw is fixed by the screw fixing bracket 15 and 24 are fixed, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com