Device for improving spacial distribution of output beams output of multimode fibers

A multi-mode fiber, spatial distribution technology, applied in the field of laser applications, can solve the problems of difficult re-adjustment, difficult to ensure consistency, inconvenient installation and adjustment, etc., to improve the spatial distribution of the output beam, reduce the sensitivity, and achieve a uniform output spot. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

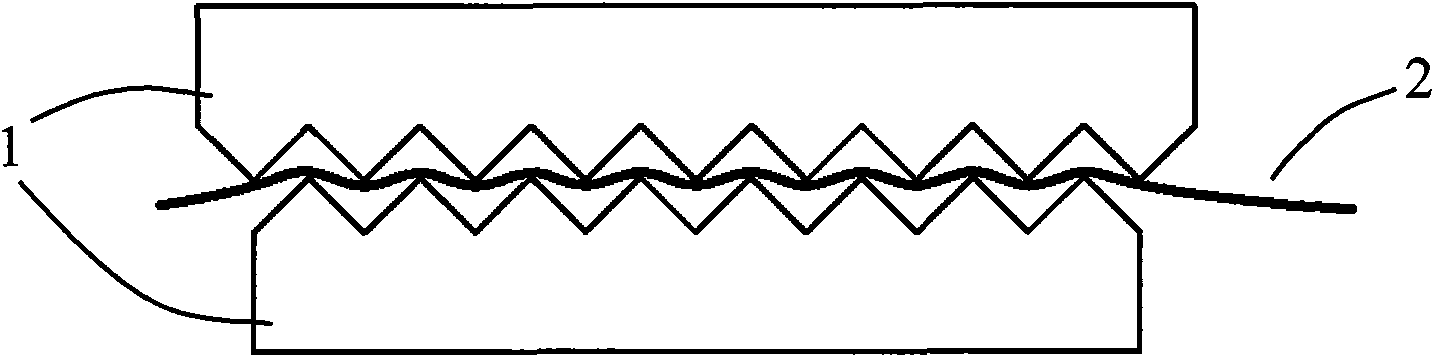

[0015] Apply multi-point stress to a small section of optical fiber, such as figure 1 The structure shown is implemented. Two workpieces (1) with jagged surface undulations are made, the saw teeth are arranged in a staggered manner, the optical fiber (2) is clamped in the saw teeth on both sides, and pressure is applied. At this time, the optical fiber (2) will be bent under strong pressure at the contact point with each sawtooth, and stress will be generated inside it. By changing the pressure, the light output through the optical fiber (1) can achieve an ideal distribution condition, and at this time, glue or screws are used to fix the workpiece (1) and the optical fiber (2). In this example, the undulations on the workpiece (1) are jagged, and other uneven shapes can also be designed in actual use.

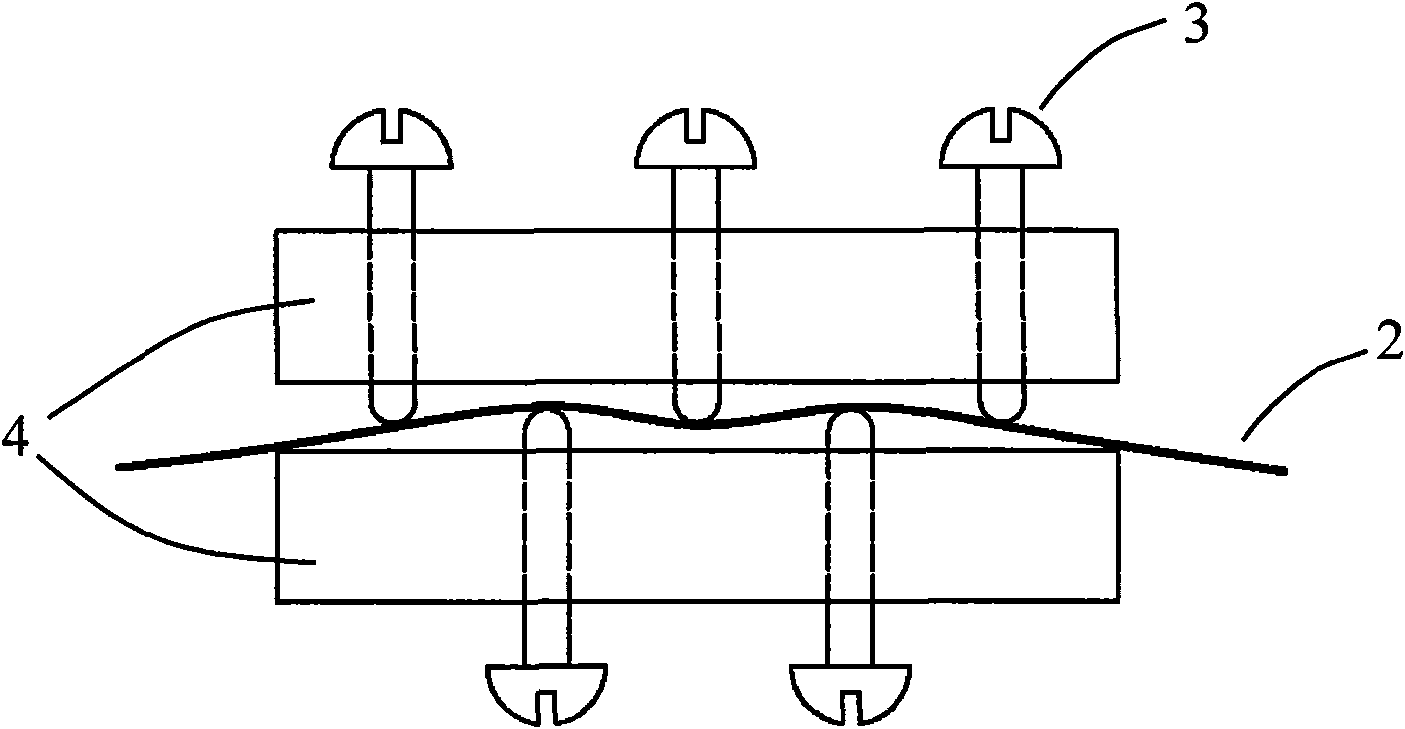

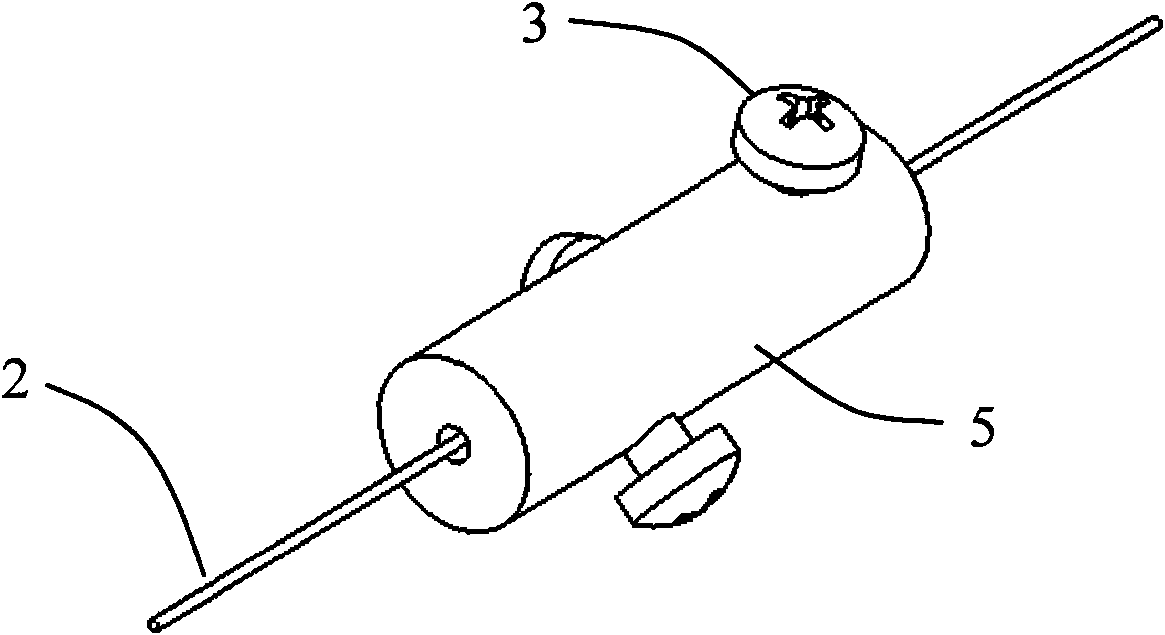

[0016] figure 2 A structure that can adjust the pressure of each pressure point of the optical fiber is shown. The screw (3) is screwed on the screw seat (4), the optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com