Manufacturing method for jaw defect individual restoration

A technology of prosthesis and manufacturing method, which can be used in bone implants, medical science, surgery, etc., and can solve the problems of exposure, short service life of prosthesis, and poor recovery function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

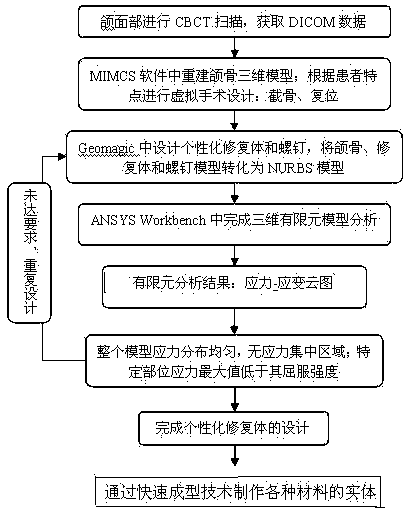

[0026] In the present invention, the method for preparing a personalized restoration for a jawbone defect is characterized by comprising the following steps:

[0027] (1) Perform a CBCT scan on the patient's maxillofacial region to obtain DICOM data:

[0028] Due to the complex anatomical relationship of the oral and maxillofacial region, it is difficult to determine the location and scope of the jaw bone lesions through plane graphics. Using digital model surgery technology can provide doctors with a three-dimensional model, which can intuitively diagnose jaw diseases and formulate surgical plans. , thereby avoiding damage to important anatomical structures.

[0029] (2) Import the data into the 3D modeling software-MIMCS (Materialise, Belgium) to reconstruct the 3D model of the jaw; perform virtual surgical design according to the patient's characteristics: simulate the reduction of bone fractures with obvious displacement of the stump, and perform infection or tumor fractur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com