High-quality tobacco leaf baking process

A curing process and tobacco leaf technology, which are applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problem that the curing process technology is not suitable for the design requirements of the vertical air-lift type intensive automatic curing room and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

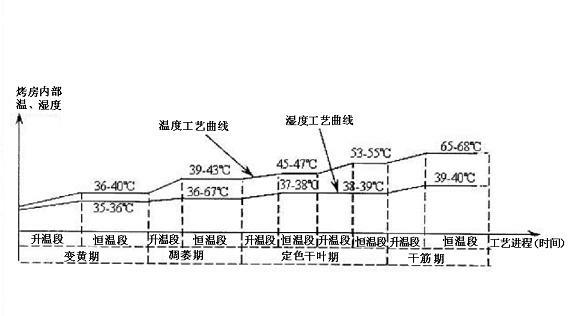

[0020] The technical solution will be further described below in conjunction with the accompanying drawings as an example.

[0021] This example uses a vertical airflow ascending intensive automatic curing barn. There are 5 tobacco leaf baking racks from bottom to top in the barn. Input the baking data indicated in the curve in the computer of the control system, place a PT100 with a resolution of 0.1°C and a detection accuracy of 0.25% in the baking room as a temperature sensor, connect the temperature and humidity data collected by the sensor to the control computer, and ignite That's it. The specific operation is as follows:

[0022] 1. Yellowing period

[0023] (1) Raise the dry bulb temperature to 30°C at a rate of 1°C / h, keep the temperature constant for 7±0.4-0.7 hours, and wait for the tip of the tobacco leaves on the first tobacco leaf drying rack to turn yellow to 60%;

[0024] (2) Raise the dry bulb temperature from 30°C to 35°C at a speed of 1°C / h, and keep the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com