Automatic laminating production line for transformer iron cores

A transformer core and production line technology, applied in the manufacture of inductors/transformers/magnets, parts of transformers/inductors, electrical components, etc., can solve problems such as long stacking cycle, difficult quality assurance, and failure rate, and achieve automation High level, beautiful appearance, and the effect of stacking accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

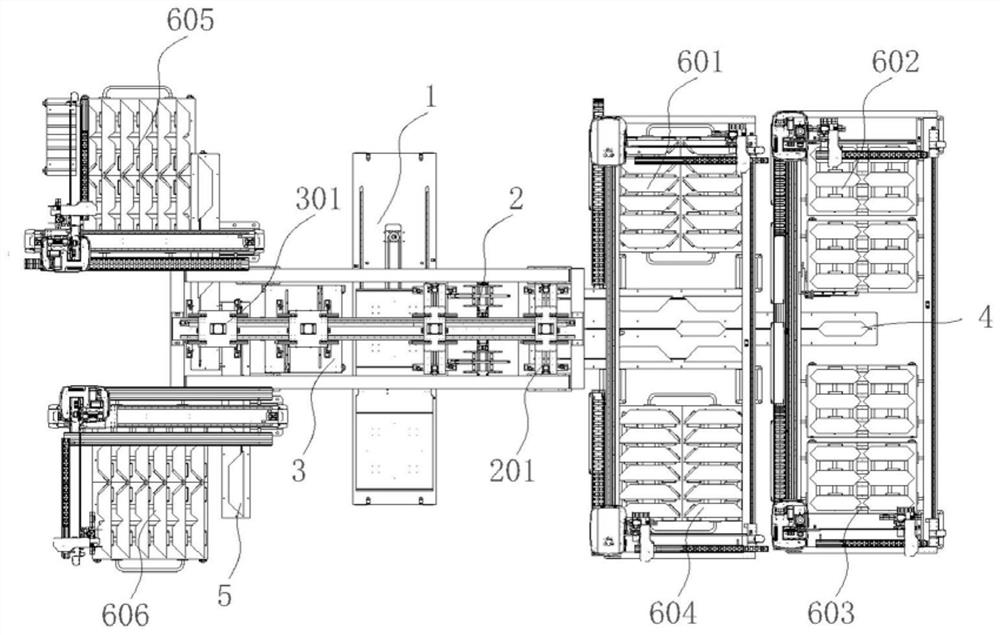

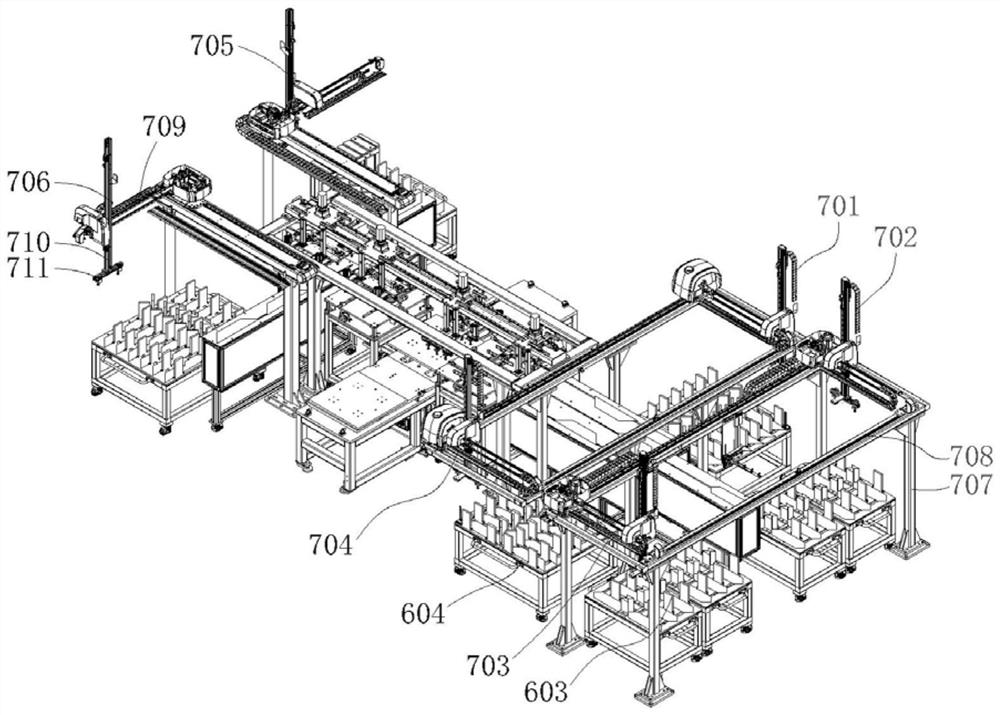

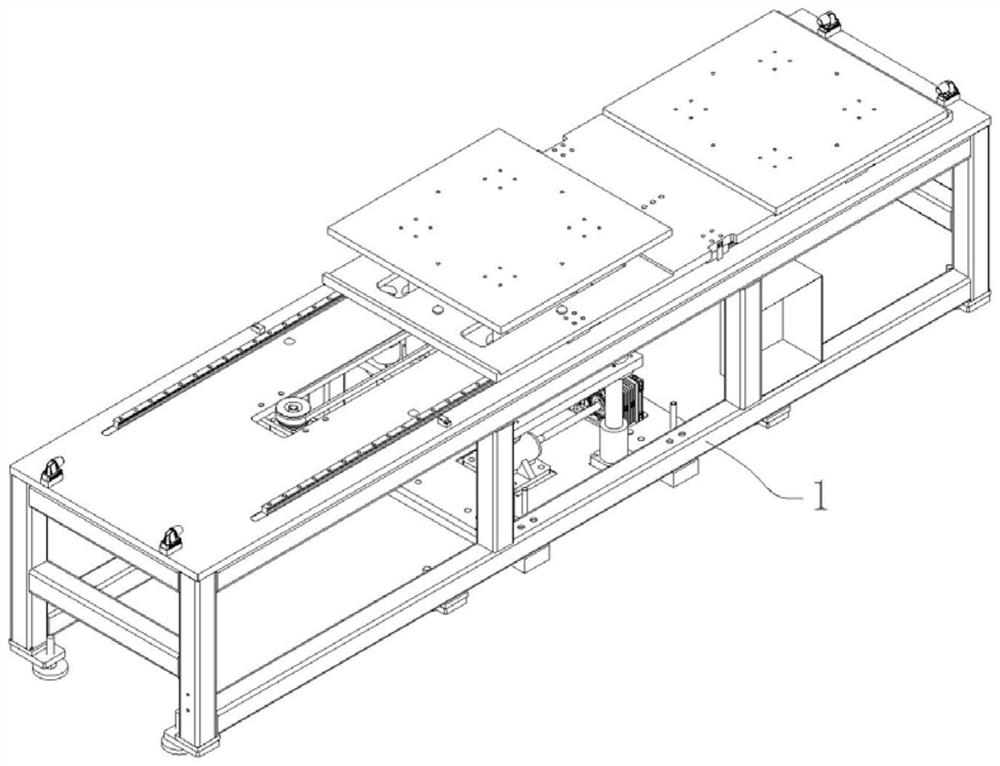

[0064] Combine below Figure 1 to Figure 23 Each accompanying drawing of the present invention is described in detail.

[0065] In this embodiment, a three-phase transformer is taken as an example. The silicon steel sheets A, B, and C are respectively the three core columns of the iron core, wherein the silicon steel sheet B is the middle column; the silicon steel sheets D and E are the upper and lower yokes respectively.

[0066] combine figure 1 with figure 2 , a transformer core automatic stacking production line according to the present invention, comprising a transformer core automatic lamination table 1, and the two sides of the automatic lamination table 1 are respectively provided with a column fine positioning device 2 and a yoke fine positioning device 3 , the column sheet fine positioning device 2 is connected with the column sheet conveying device 4, the yoke sheet fine positioning device 3 is connected with the yoke sheet conveying device 5, and the initial end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com