Production method for completely-fermented mulberry wine and product

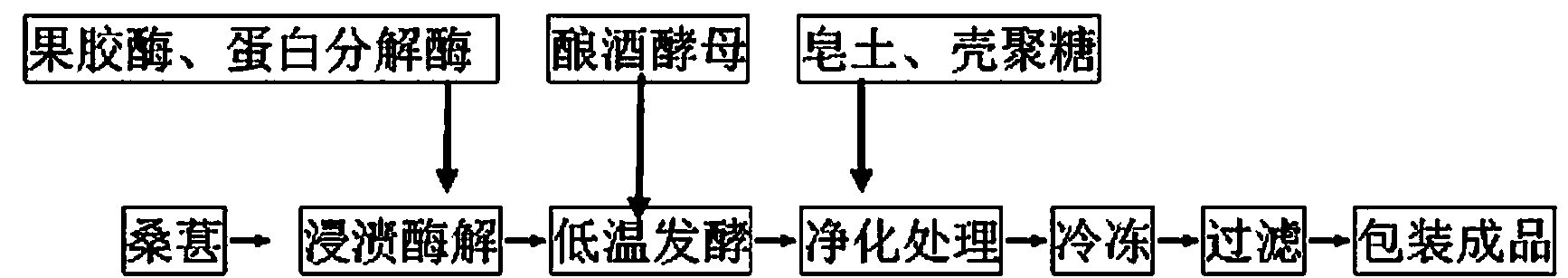

A production method and technology of mulberry wine, which are applied to the production method of fully fermented mulberry wine and its products, can solve the problems of insufficient aroma extraction, lack of flavor of nourishing wine, poor stability, etc., and achieve good compound enzymolysis effect, Improve stability, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Selected raw materials, requiring more than 80% of the fresh fruit to be mature, no rotten fruit, no disease fruit, crush it with a beating machine, and add SO at 42mg / L 2 , Transfer the mulberry pulp into a temperature-controlled enzymatic hydrolysis tank, add 25mg-50mg of pectinase and 110mg-140mg of proteolytic enzyme per liter of juice, stir evenly, control the enzymatic hydrolysis temperature at 12℃~16℃, enzymatic hydrolysis for 8.5 hours ~13 hours. The juice yield can reach more than 70%,

[0024] Transfer the above-mentioned enzymolysis clear juice to the fermentation tank, add the activated dry yeast of French Raman company EC1118, slowly add (165~215)mg / L, stir evenly, and control the fermentation temperature at 15℃~ 21℃, after 16 days to 25 days of pre-fermentation, the clear juice is separated from the fermentation broth, transferred to another tank, and the clear juice is further fermented for 12 to 22 days to obtain the fermented raw wine liquor; in the fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com