Electrolytic copper foil with low roughness surface and process for producing the same

a technology of copper foil and low roughness, which is applied in the direction of printed circuit manufacturing, printed circuit aspects, and the improvement of the adhesion of the metal to the substrate, etc., can solve the problems of low roughness of the foil moderate uneven surge on the roughness surface, and difficult to reduce the difference in roughness between gloss surface and roughness surface. , to achieve the effect of low roughness surfa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

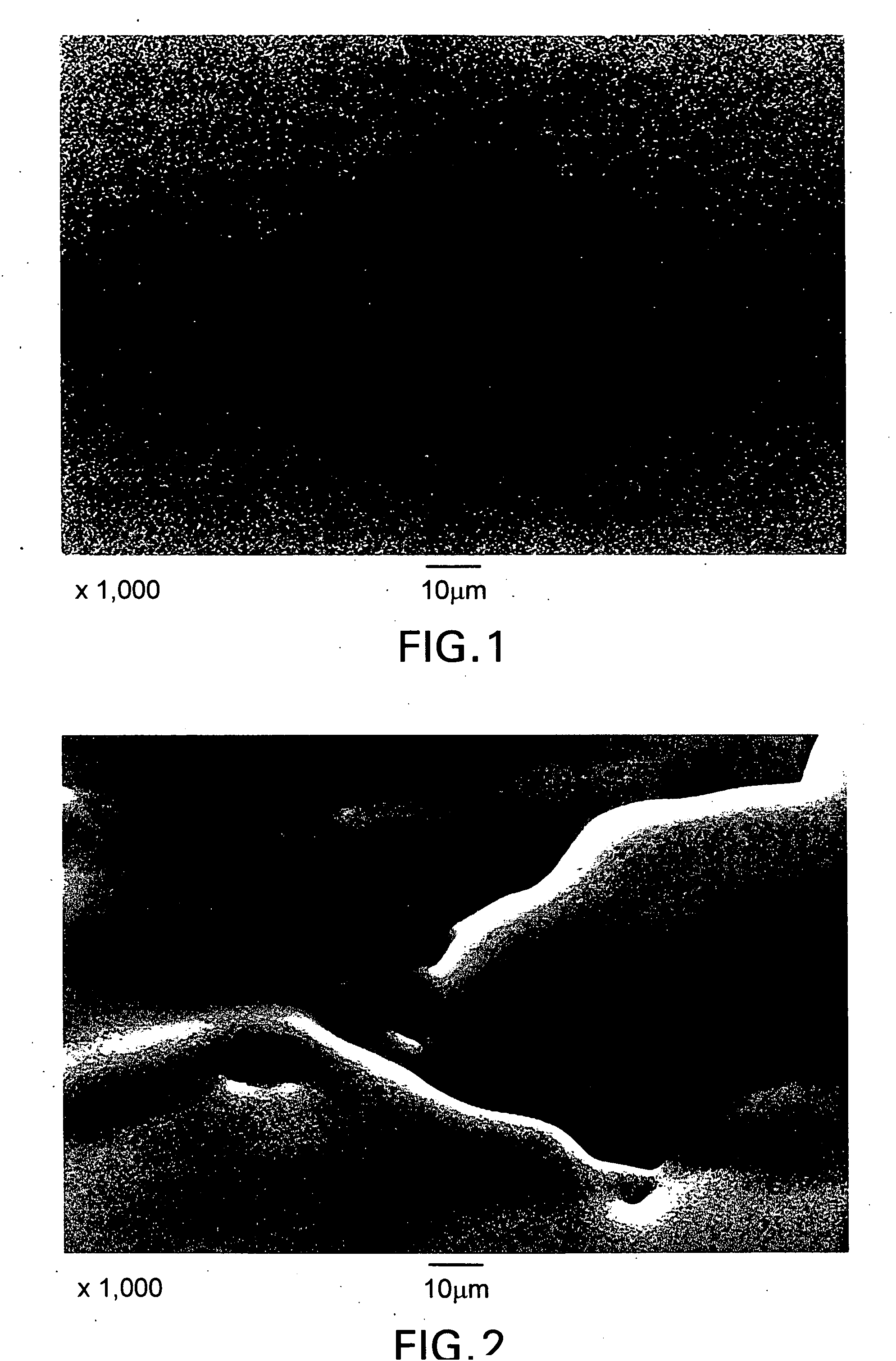

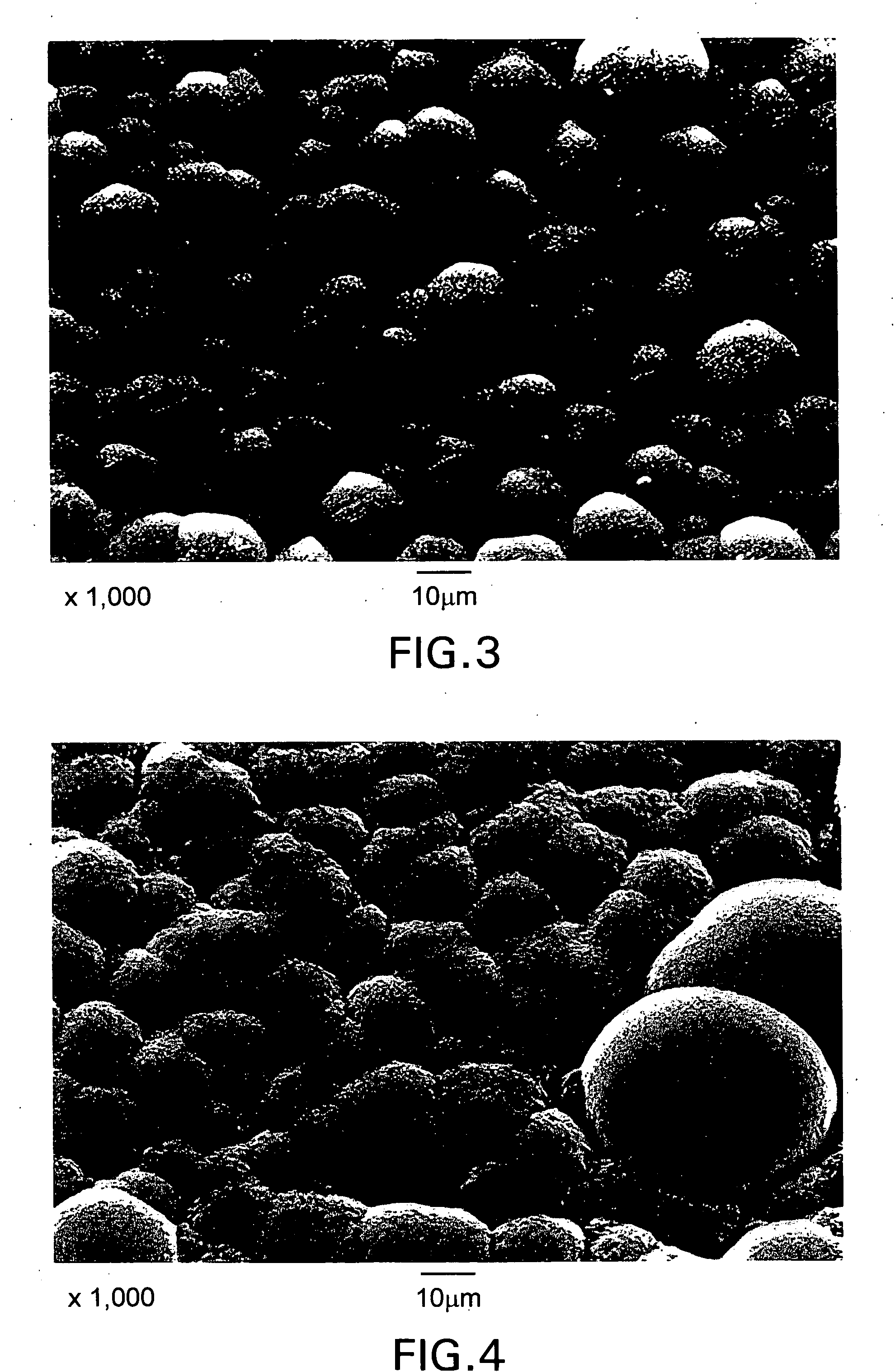

[0051] Best mode for carrying out the invention will be described below.

[0052] An electrolyte of an aqueous solution of sulfuric acid / copper sulfate comprising 100 g / L of sulfuric acid (H2SO4) and 280 g / L of copper sulfate pentahydrate (CuSO4.5H2O) was prepared (hereinafter, this electrolyte is referred to as “basic electrolyte”).

[0053] As additives, polyethylene glycol (average molecular weight 20000, product of Sanyo Chemical Industries, Ltd.), polyethyleneimine (“EPOMIN (product name), Product number: P-1000, Nippon Shokubai Co., Ltd., weight average molecular weight: 70000), sodium 3-mercapto-1-propane sulfonate, and hydrochloric acid were added to the basic electrolyte such that 30 mg / L of polyethylene glycol, 0.5 mg / L of polyethyleneimine, 220 μmol / L of sodium 3-mercapto-1-propanesulfonate and 35 mol / L of chloride ions were achieved.

[0054] The electrolyte containing these additives was allowed to flow between a titanium plate coated with an oxide of Platinum Group serving a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com