Aluminum alloy coating

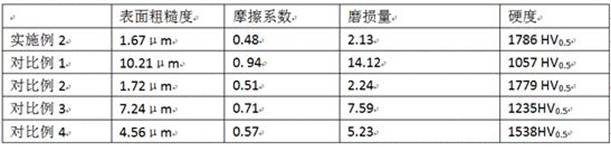

A technology of aluminum alloy and coating, applied in the direction of coating, surface reaction electrolytic coating, electrolytic coating, etc., can solve the problems of limitation, wear resistance, poor corrosion resistance, etc., achieve low friction coefficient, film quality improvement, Effect of Low Roughness Surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] An aluminum alloy coating is prepared by the following steps:

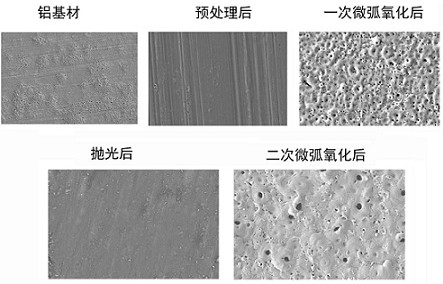

[0059] (1) Pretreatment of aluminum alloy surface: heat treatment, mechanical polishing, degreasing and degreasing, washing and drying;

[0060] The heat treatment is to place the aluminum alloy in an inert atmosphere of 350° C., and keep it at a constant temperature for 30 minutes;

[0061] The mechanical polishing is to grind the aluminum alloy step by step under the conditions of 60#, 300#, 1000#, and 2000# sandpaper successively;

[0062] The degreasing and degreasing is carried out by using an alkaline degreasing solution. The components of the alkaline degreasing solution are as follows: sodium bicarbonate 42g / L, sodium carbonate 38g / L, EDTA 5g / L, temperature 43°C, time 5min.

[0063] The water washing is to use deionized water at 45° C.;

[0064] The drying treatment is air purging;

[0065] (2) One-time micro-arc oxidation treatment: The micro-arc oxidation electrolyte is NaOH 5g / L, Na2SiO3 11 g...

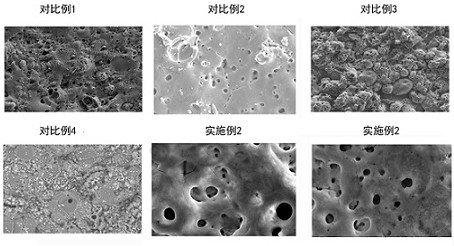

Embodiment 2

[0071] An aluminum alloy coating is prepared by the following steps:

[0072] (1) Pretreatment of aluminum alloy surface: heat treatment, mechanical polishing, degreasing and degreasing, washing and drying;

[0073] In the heat treatment, the aluminum alloy is placed in an inert atmosphere at 355° C. for 35 minutes at a constant temperature.

[0074] The mechanical polishing is to grind the aluminum alloy step by step under the conditions of 60#, 300#, 1000#, and 2000# sandpaper in sequence.

[0075] The degreasing and degreasing is carried out by using an alkaline degreasing solution. The components of the alkaline degreasing solution are as follows: sodium bicarbonate 42g / L, sodium carbonate 38g / L, EDTA 5g / L, temperature 43°C, time 5min.

[0076] The water washing is rinsing with deionized water at 45°C.

[0077] The drying process is air purging.

[0078] (2) One-time micro-arc oxidation treatment: The micro-arc oxidation electrolyte is NaOH 6g / L, Na2SiO3 11.5g / L, NaF1....

Embodiment 3

[0084] An aluminum alloy coating is prepared by the following steps:

[0085] (1) Pretreatment of aluminum alloy surface: heat treatment, mechanical polishing, degreasing and degreasing, washing and drying;

[0086] The heat treatment is to place the aluminum alloy in an inert atmosphere of 360° C., and to stand for 40 minutes at a constant temperature;

[0087] The mechanical polishing is to grind the aluminum alloy step by step under the conditions of 60#, 300#, 1000#, and 2000# sandpaper successively;

[0088] The degreasing and degreasing is carried out by using an alkaline degreasing solution. The components of the alkaline degreasing solution are as follows: sodium bicarbonate 42g / L, sodium carbonate 38g / L, EDTA 5g / L, temperature 43°C, time 5min.

[0089] The water washing is to use deionized water at 45° C.;

[0090] The drying treatment is air purging;

[0091] (2) One-time micro-arc oxidation treatment: The micro-arc oxidation electrolyte is NaOH 7g / L, Na2SiO3 12 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com