Peelable flexible coatings, compositions and methods thereof

A composition, flexible coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, thin material processing, etc., can solve problems such as increased costs and production stoppages, production stoppages, polyurethane fractures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

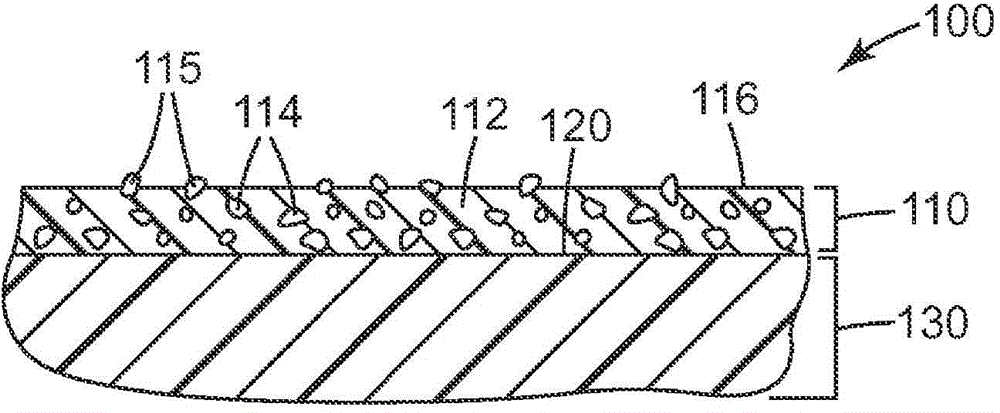

[0057] Example 1: Preparation of Polyurethane-Polyacrylic Blend Dispersion with PP Granules .

[0058] synthesis . Known under the trade names Bayhydrol UH 2593 / 1, Bayer Material Science and NeoRez R-2180, DSM NeoResins and Bayhydrol UH 240, Bayer Material Science and Bayhydrol, and NeoPac E-122, DSM NeoResins, and Bayhydrol A 2651, Bayer Material Science The various polyurethane and polyurethane-acrylic dispersions were mixed by gentle stirring for 5 min at room temperature. Second, a small amount of co-solvent such as butoxydiethylene glycol, butyl glycol, ethylene glycol ethyl ether, and diethylene glycol ethyl ether was slowly added to the mixture of polymer dispersions and stirred at 300 rpm for 5 minutes. Then, some additives such as defoamers, leveling agents and organic wax emulsions, besides polyurethane-based thickeners were incorporated into the mixture with gentle stirring. Finally, micron-sized polypropylene pellets are added. The stirring speed was 300 rpm...

example 2

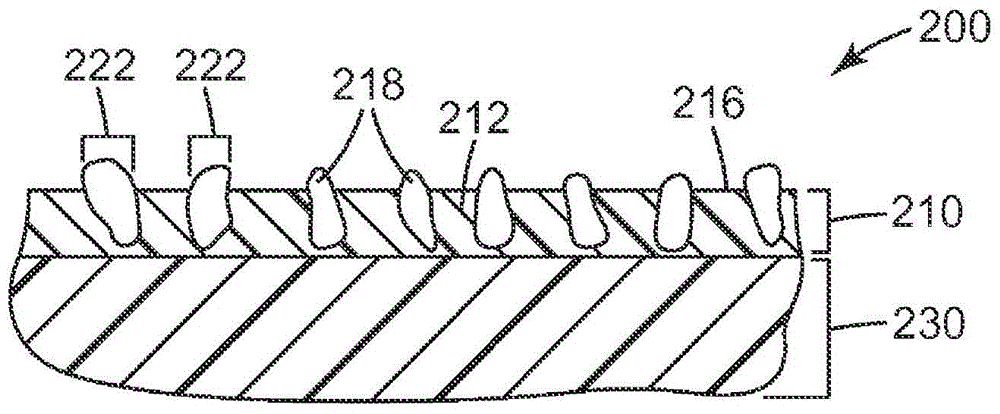

[0069] Example 2: Preparation of polyurethane-polyvinyl acetate blend dispersion with HDPE pellets prepare .

[0070] synthesis . The polyurethane dispersion (Bayhydrol UH 2593 / 1, Bayer Material Science) and the polyvinyl acetate dispersion (Acropol 63893, Nuplex Industries Ltd) were mixed with gentle stirring for 5 minutes at room temperature. Second, a small amount of co-solvent such as butoxydiethylene glycol, butyl glycol, ethylene glycol ethyl ether, and diethylene glycol ethyl ether was slowly added to the mixture of polymer dispersions and stirred at 300 rpm for 5 minutes. Additives such as defoamers, leveling agents and organic wax emulsions, besides polyurethane-based thickeners were incorporated into the mixture with gentle stirring. Finally, micron-sized high-density polyethylene (HDPE) pellets are added. The stirring speed was 300 rpm to 500 rpm for 5 min until a homogeneous coating composition was obtained. The coating composition is applied to the floor ...

example 3

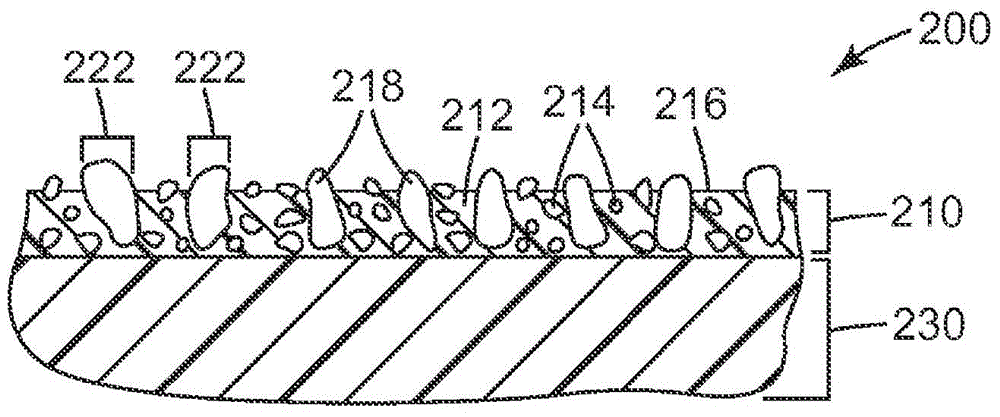

[0071] Example 3: Preparation of polyurethane-polyurethane blend dispersion with inorganic glass bubble particles prepare .

[0072] synthesis . The first polyurethane dispersion (Bayhydrol UH 2593 / 1, Bayer Material Science) and the second polyurethane dispersion (NeoRez R-2180, DSM NeoResins) were mixed with gentle stirring for 5 minutes at room temperature. Second, a small amount of co-solvent such as butoxydiethylene glycol, butyl glycol, ethylene glycol ethyl ether, and diethylene glycol ethyl ether was slowly added to the mixture of polymer dispersions and stirred at 300 rpm for 5 minutes. Then, some additives such as defoamers, leveling agents and organic wax emulsions, besides polyurethane-based thickeners were incorporated into the mixture with gentle stirring. Finally, micron-sized inorganic glass bubble particles (glass bubbles K 46,3M) are added. The stirring speed was 300 rpm to 500 rpm for 5 min until a homogeneous coating composition was obtained. The co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com