Method for measuring spherical curvature radius

A technology of curvature radius and measured surface, which is applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problem of not being able to obtain the size of the radius of curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. It is necessary to point out that the following examples are only used for further description of the present invention, and cannot be interpreted as limiting the protection scope of the present invention, and those skilled in the art make some non-essential improvements to the present invention according to the above-mentioned content of the present invention And adjustments still belong to the protection scope of the present invention.

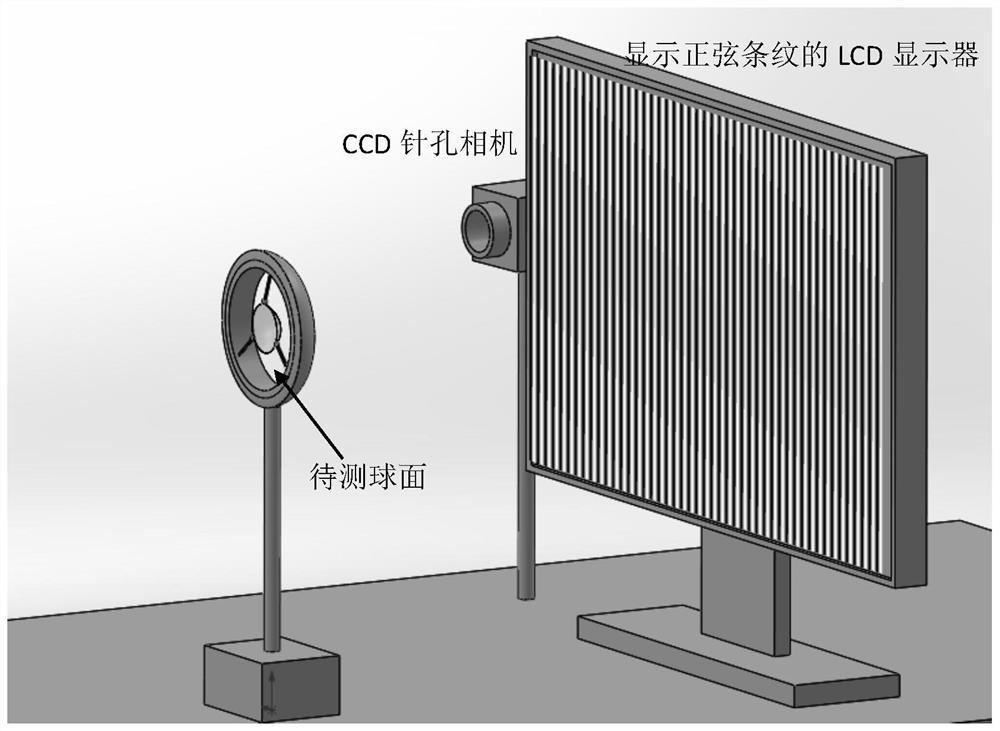

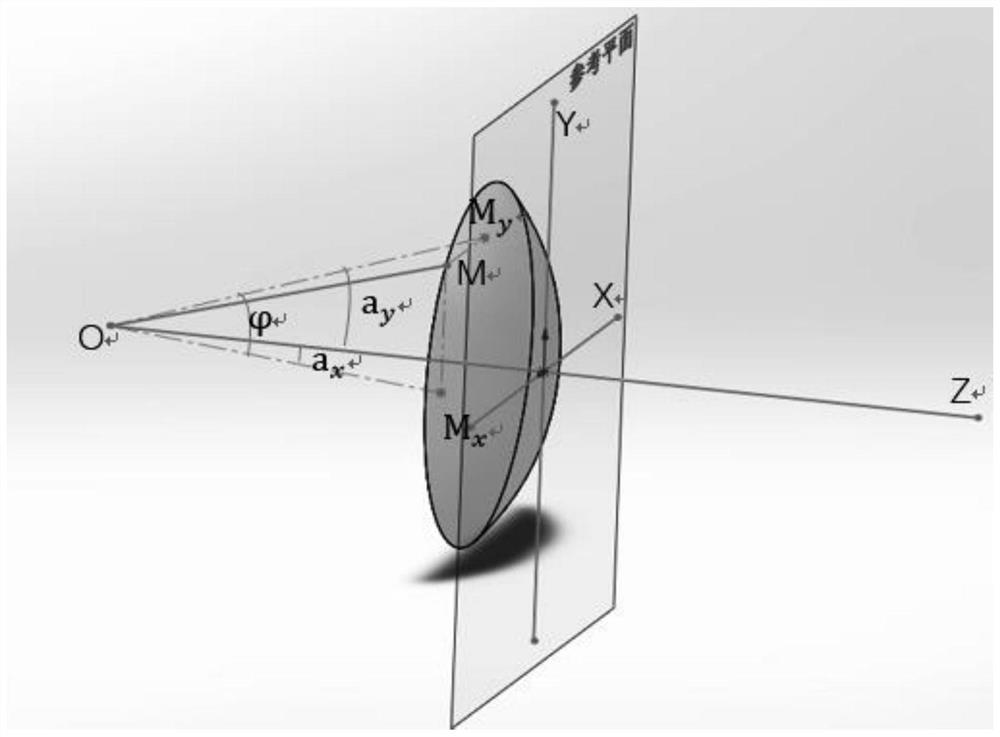

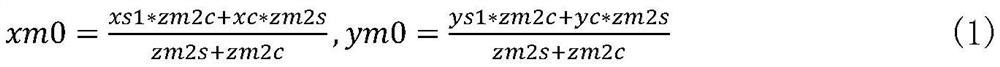

[0023] attached figure 1 The sinusoidal stripes are displayed on the middle LCD display, which are respectively reflected by the reference plane mirror and the spherical surface to be tested, and captured by the CCD pinhole camera. The camera pinhole coordinates C(Xc,Yc), and the display coordinates S1(Xs1,Ys1) and S2(Xs2,Ys2) of a ray reflected by a plane and a sphere, where the display coordinates are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com