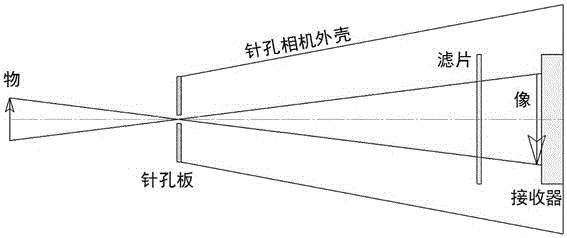

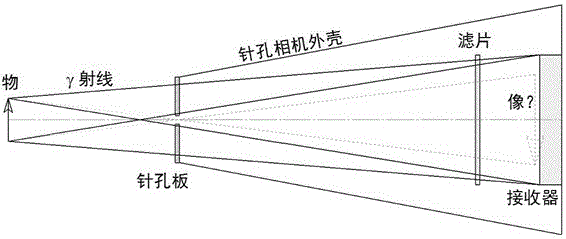

X-ray pinhole camera for intense laser light condition and installation and adjustment method

A pinhole camera and X-ray technology, which is applied in optics, instruments, photography, etc., can solve problems such as X-ray pinhole camera failure, and achieve the effects of saving adjustment time, increasing accuracy, and improving signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

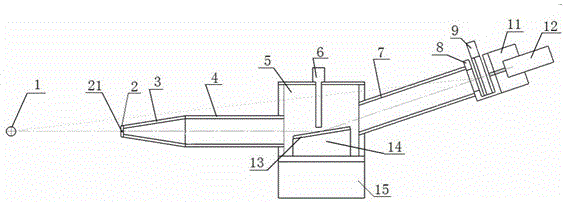

[0034] Such as image 3 , Figure 4 with Figure 5 As shown, this embodiment is used for an X-ray pinhole camera under strong laser conditions, and the pinhole camera includes a pinhole plate 2, a pinhole seat housing 3, a front light tube 4, a grazing incidence mirror chamber, and a rear light tube 7. Film chamber 8, film cassette 9, filter frame 10, filter disc 10-1, negative film 10-2, two-dimensional adjustment laser seat 11, semiconductor laser 12 and two-dimensional adjustment frame 15, in the film chamber 8 A two-dimensional adjustment laser seat 11 is fixedly arranged on the outside, and a semiconductor laser 12 is installed on the side corresponding to the film chamber 8 on the two-dimensional adjustment laser seat 11. A through hole for adjusting the passage of the laser light; the grazing incidence mirror chamber includes a mirror chamber housing 5, a light blocking lead plate 6, a grazing incidence mirror 13 and a two-dimensional adjustment grazing incidence mirr...

Embodiment 2

[0047] Such as image 3 , Figure 4 with Figure 5 As shown, the present embodiment is used for an X-ray pinhole camera under strong laser conditions. In order to realize high-temperature plasma X-ray imaging under strong laser irradiation and high background noise conditions, the pinhole camera includes a pinhole plate 2, a pinhole Housing housing 3, front light tube 4, grazing incidence mirror room, rear light tube 7, film chamber 8, film box 9, filter frame 10, filter 10-1, film 10-2, two-dimensional adjustment laser Seat 11, semiconductor laser 12 and two-dimensional adjustment frame 15, two-dimensional adjustment laser seat 11 is fixedly arranged on the outside of described film chamber 8, semiconductor laser is installed on the side corresponding to film chamber 8 on two-dimensional adjustment laser seat 11 12. At the optical axis positions of the two-dimensional adjustment laser seat 11 and the film chamber 8, there are through holes for the adjustment laser to pass t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com